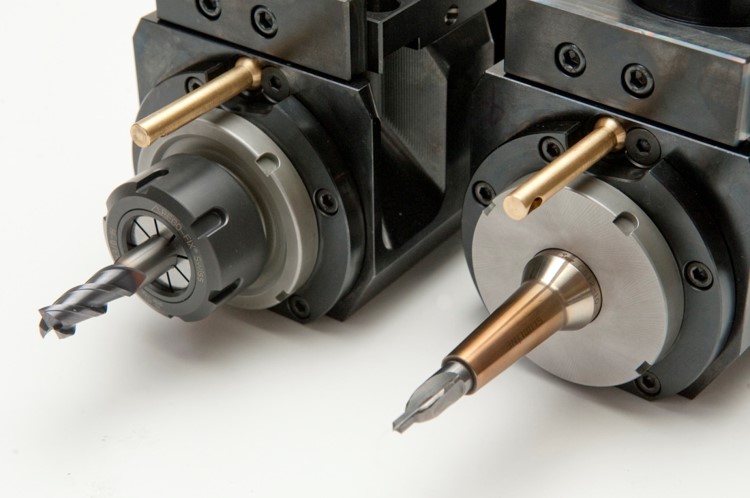

Repair of milling units for lathes Kitou Seiki

More than 2,000 units of reparing result

Are you having trouble with repairs and high costs for the milling unit used in combined lathes?

Kito Seiki provides high quality and low cost service.

http://kaitenkougu.com/

Here are repare service details.

①Disassembling, cleaning, and inspecting the milling unit to make a quotation.

Divide into parts that are still usable and parts that are no longer usable.

-

Before cleaning

-

After cleaning

We will submit a quotation and survey report at this time.

If you do not want to repair after receiving a quotation, we will return in the "disassembled condition".

It is possible to make a quotation just by the appearance, but if damage is found during repare, the quotation need to be revised.

We recommend to make a quotation with disassembled condition.

If you agree to the quotation, next process is as follows.

②Check the runout accuracy of the drive shaft and machining shaft.

③Reworking unusable parts by theirs master craftsmanship.

The accuracy will be as good as new.

-

④Assemble cleaned and reworked parts.

-

⑤Measure geometric tolerances with a coordinate measuring machine and guarantee static accuracy.

⑥Measure noise, and heat generation with a rotation test device and guarantee dynamic accuracy.

ALL Done!

We will report the repair result with the inspection report.