Proposal of proper tool selection depending on workpiece hardness <4Gmills>

INDEX

Outline

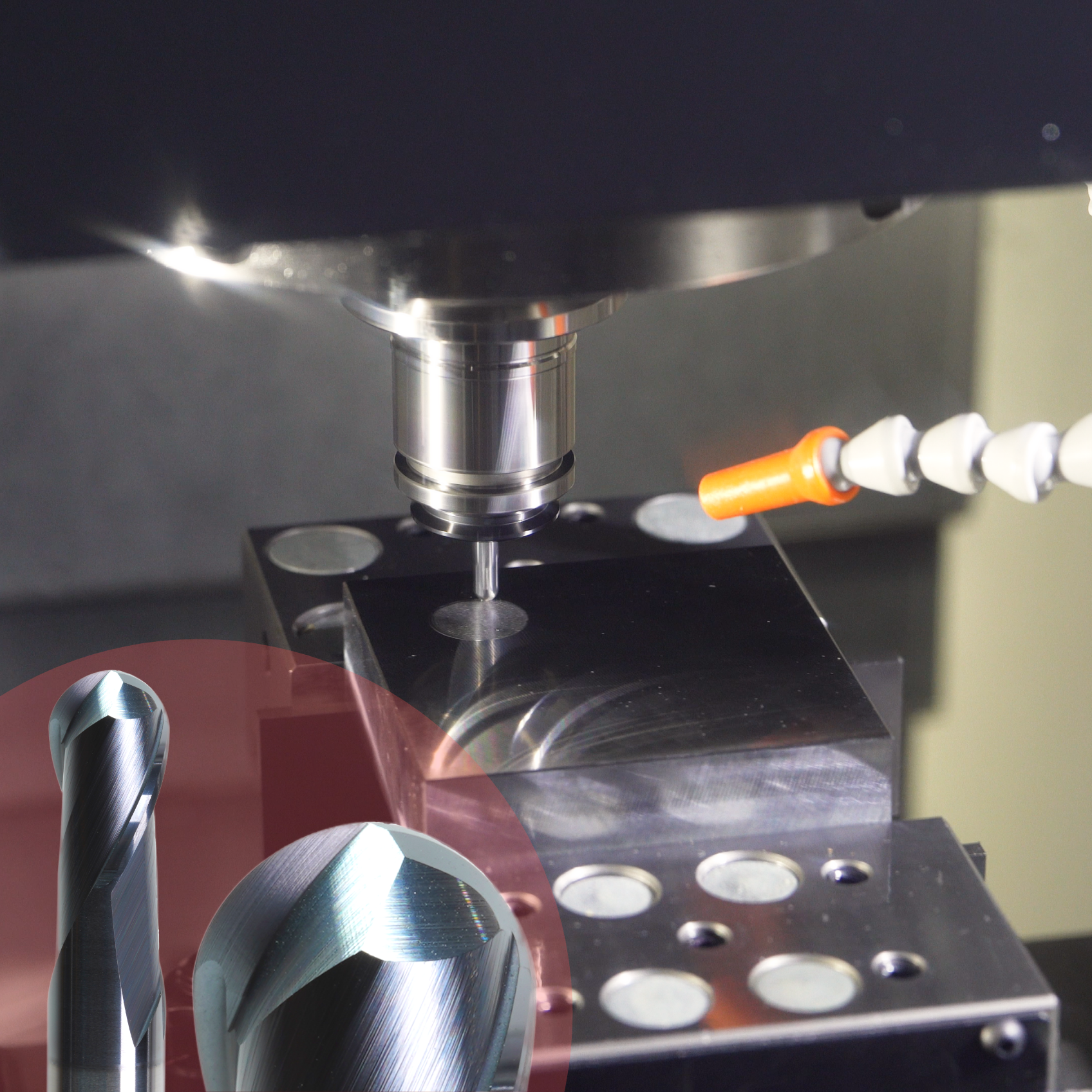

Previously, we introduced 4Gmills as"New option of endmill process for HRC40~55".This time, we tested to compare to a tool for hardened material which is top share in Japan.

We tried to confirm whether 4Gmills can show advantages from the range of pre-hardened steel which is soft material among with hardened steel, and mold steel which is hard material among with hardened steel, since HRC 20 to 50 is recommended application range by the manufacturer.

Test report

-

Machine: Mazak VCN-430A (BT40)

-

Workpiece clamping condition:

120mm square x 40mm height

Workpiece material:

DAC MAGIC (HRC45,50), PCM30 (HRC30)

Testing tools for HRC45 and HRC50

Tested with Φ6 ball endmill.Cutting conditions

Rough cutting: Vc=180, f=0.2/rev, F=1,910mm, ap=0.3, ae=0.6

Finish cutting: Vc=180, f=0.2/rev, F=1,910mm, ap=0.1, ae=0.1

-

4Gmills

Item No. SEMD98 060080E

-

Japanese top share endmill A for high hardened material (referred below as endmill A)

Top share products which has distinctive coatings.

Test result

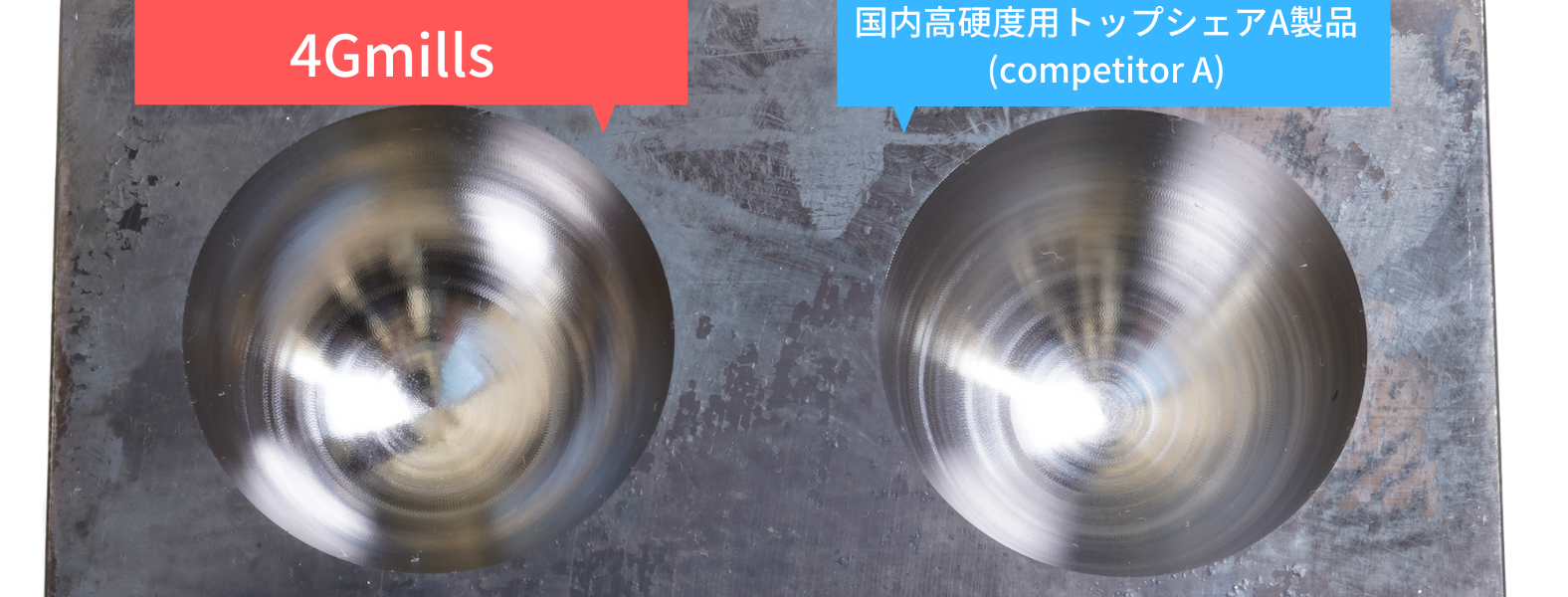

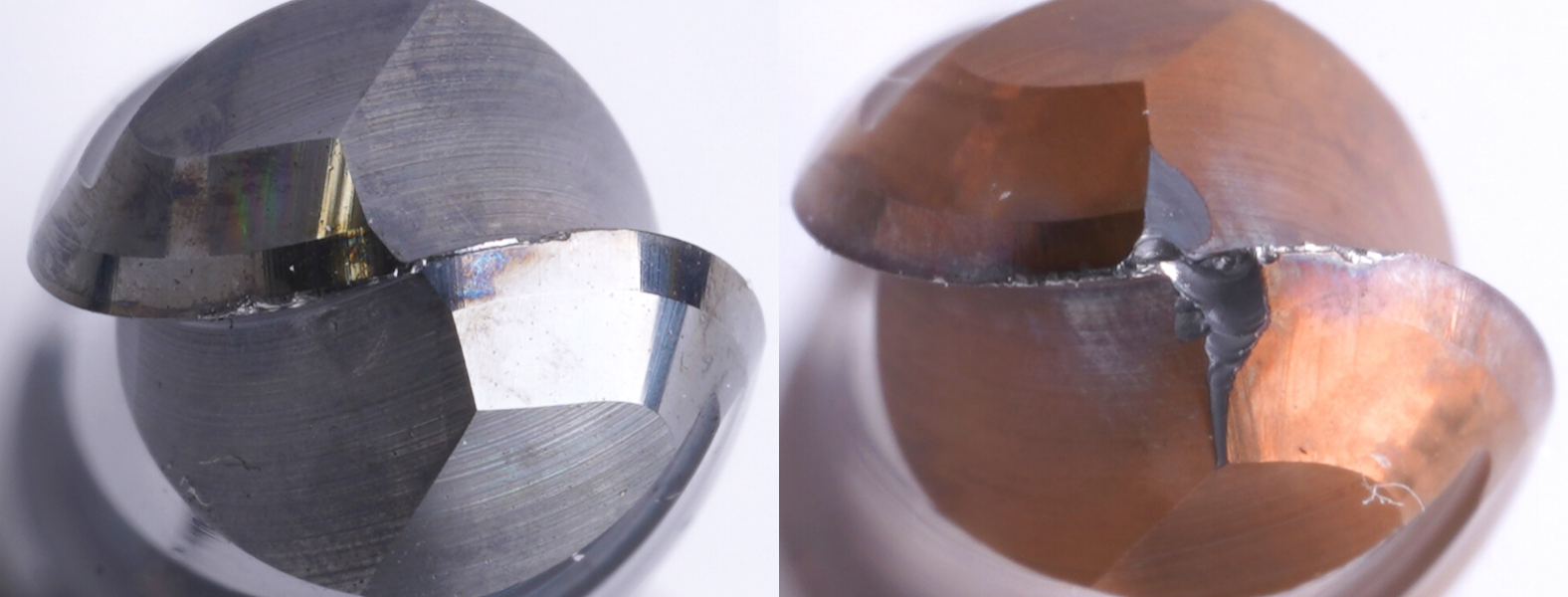

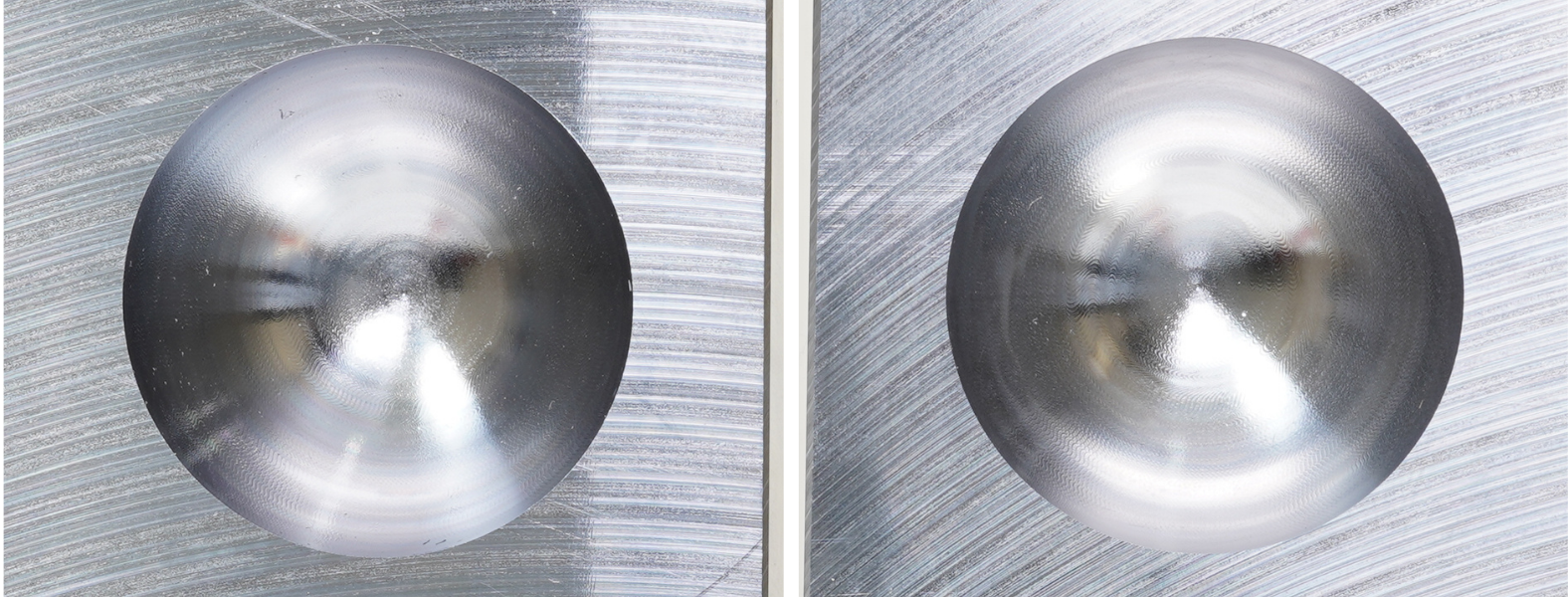

Workpiece condition after 303 min (approx. 5 hours) machining on HRC45

Left is machinined with 4Gmills, and right is machined with endmill A for high hardened material.Cloudiness is remarkable on the processed surface by endmill A compared to the processed surface by 4Gmills.

Rake face condition after 303 min (approx. 5 hours) machining on HRC45

Tool tip condition after 303 min (approx. 5 hours) machining on HRC45

The central part of endmill A is damaged.

4Gmills is longer tool life when machining of workpiece hardness of about HRC 45.

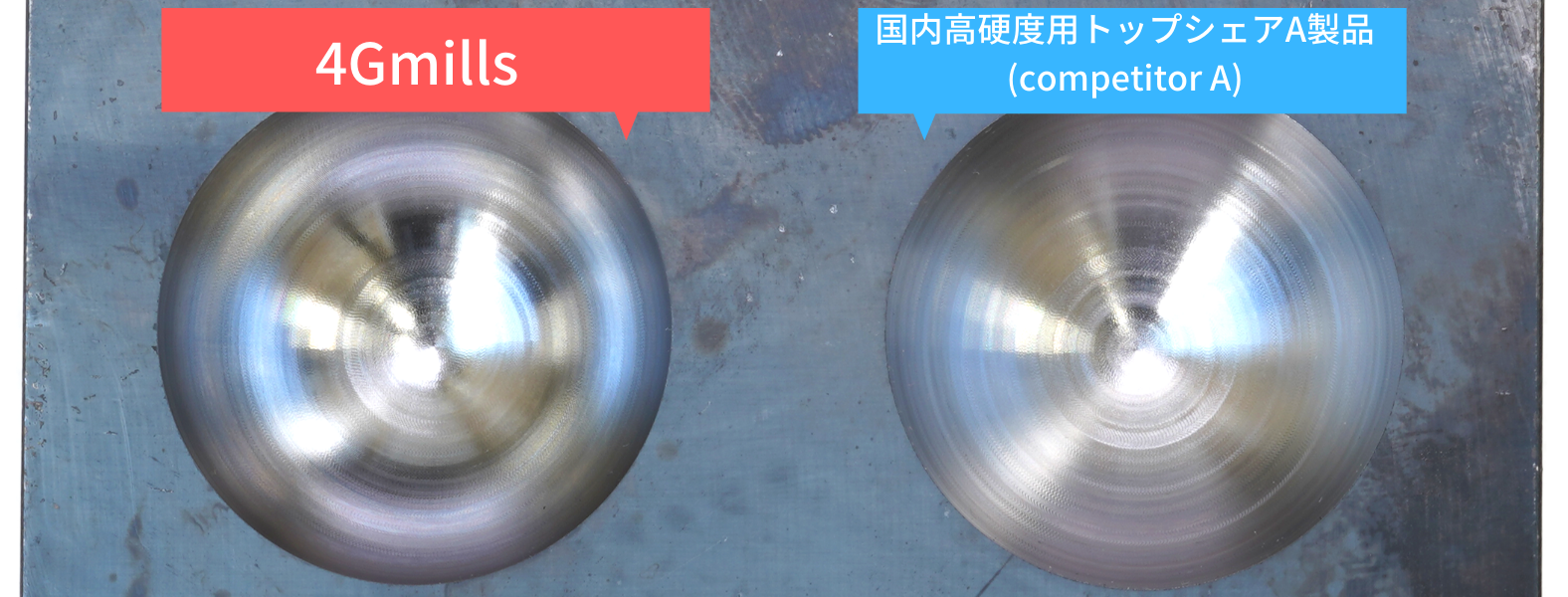

Workpiece condition after 390 min (approx. 6.5 hours) machining on HRC50

Left is machinined with 4Gmills, and right is machined with endmill A for high hardened material.Cloudiness is remarkable on the processed surface by endmill A compared to the processed surface by 4GMills.

Rake face condition after 390 min (approx. 6.5 hours) machining on HRC50

Tool tip condition after 390 min (approx. 6.5 hours) machining on HRC50

Once check from the rake side, it is less wear by 4Gmills machining.

Testing tools for HRC30

Tested increasing only feed, f=0.28 (0.14/tooth), since the tool life is supposed to be long with HRC30.

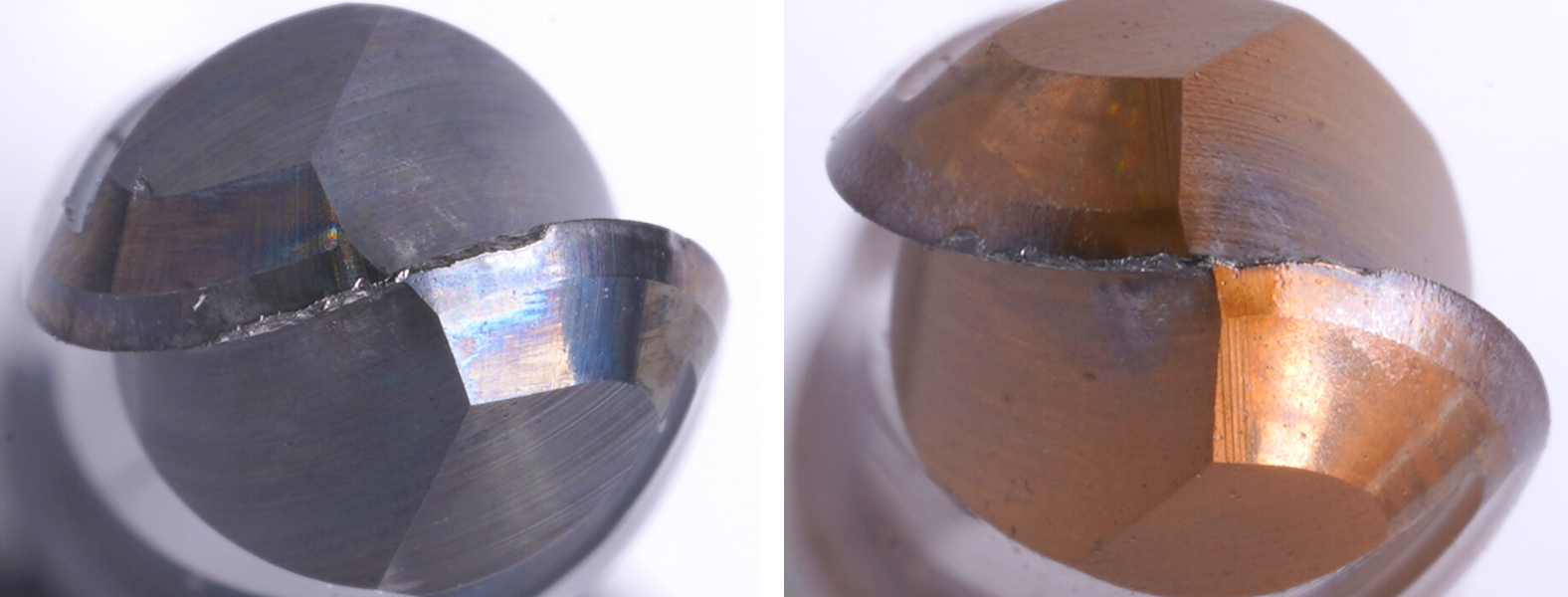

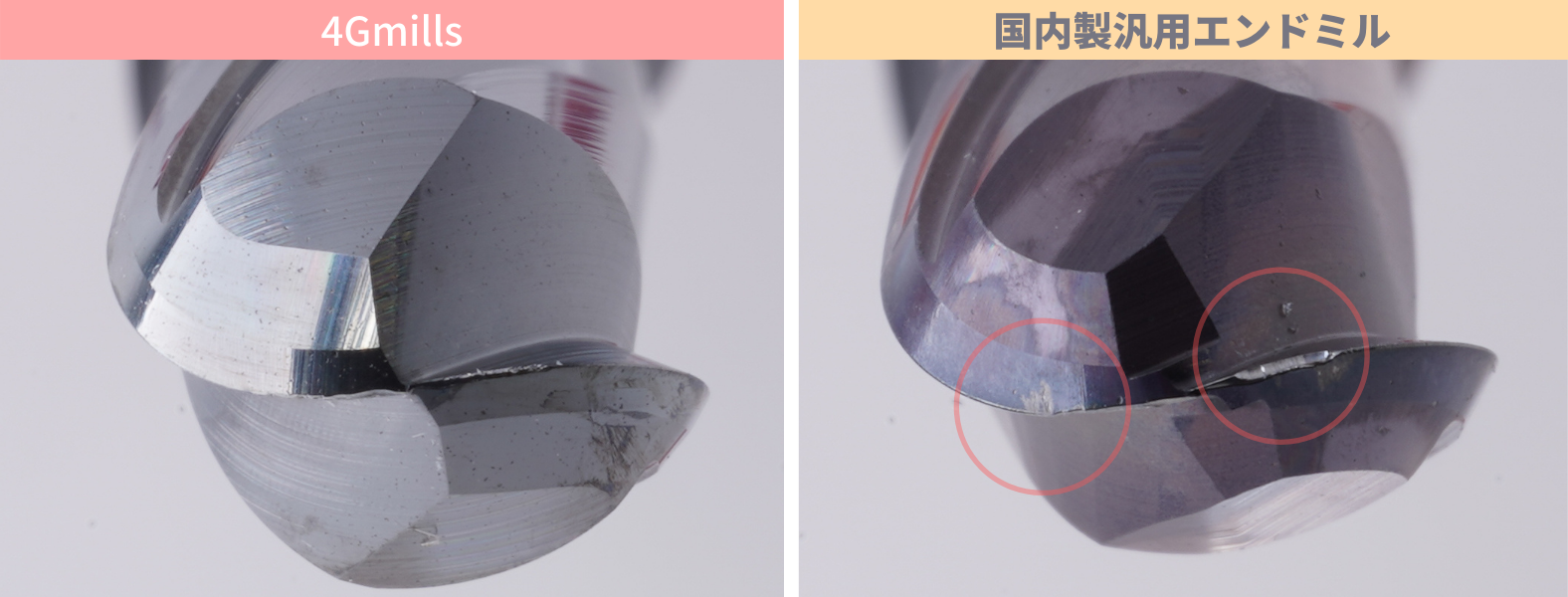

Tool tip condition after 265 min (approx. 4.5 hours) machining on HRC30

It was worn and damaged on the tool tip of general-use endmill (center).On the other hand, 4Gmills and Japanese general-purpose end mill B did not show any significant wear or damages, so these two were continuously tested.

Tool tip condition after 530 min (approx. 9 hours) machining on HRC30

The Japanese general-use endmill B got suffered large wear and damages after 530 minutes of machining.

On the other hand, 4Gmills just have a small amount of wear.

Workpiece condition after 530 min (approx. 9 hours) machining on HRC30

Application range

The light pink part shows the application range of 4Gmills on the catalog specifications.The dark pink part shows advantages range which is found by the test in Cominix technical center this time compared to Japanese top share tool A and B.

We did not test materials with lower hardness than HRC30 this time, but considering the comparison with HRC30, it is supposed to be good results.

Target steel material example

Heat-treated steel: S30C, SCr435, SCM435, etc.

Hardened steel: SKD61, SNCM431, etc.

*Reference: Akiyoshi Yokoyama (2012), 元素から見た鉄鋼材料と切削の基礎知識 (Basic knowledge of steel materials and cutting from the view point of element), THE DAILY INDUSTRIAL NEWS, 232P.

Explanation video

Ball endmill comparison test by different hardness

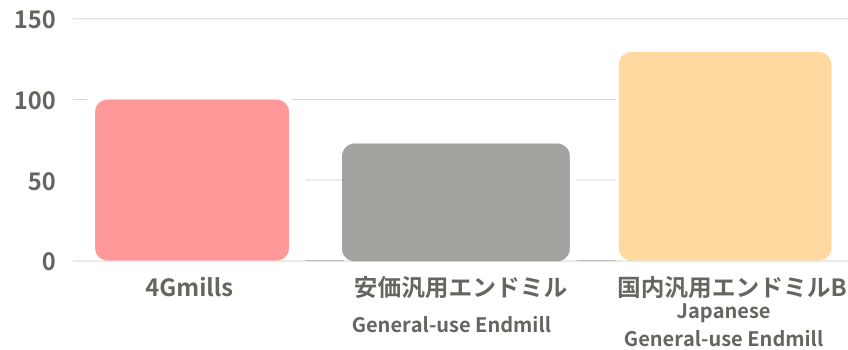

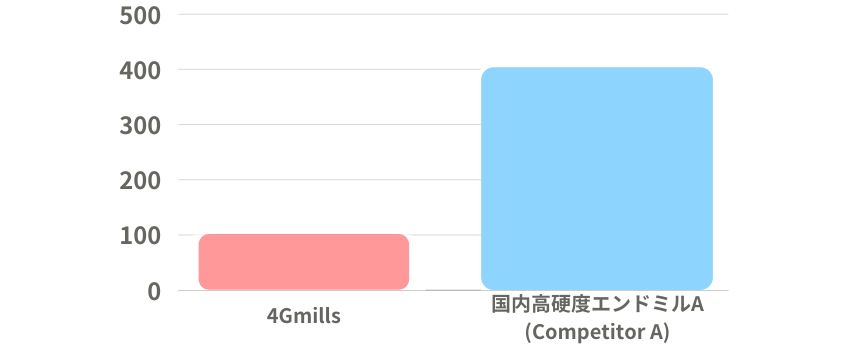

Cost comparison

4Gmills SEMD98 060080E: Price comparison when Φ6 ball endmill is 100.Excellent price advantage compared to Japanese endmill A.

Excellent price advantage and performance compared to Japanese ball endmills.