New option of endmill process for HRC40~55

Solid carbide endmills for pre-hardened steel

This is recommended for high speed machining of pre-hardened steel from HRC40~55 and hardened steel.

The tool cost is competitive compared to the equivalent tools of Japanese manufacturer.

Save tool cost

Optimal tooth design for HRC40~55 workpiece.

This product allows to reduce cutting force and vibration.

This allows to extend tool life for high speed machining of pre-hardened steel and hardened steel.

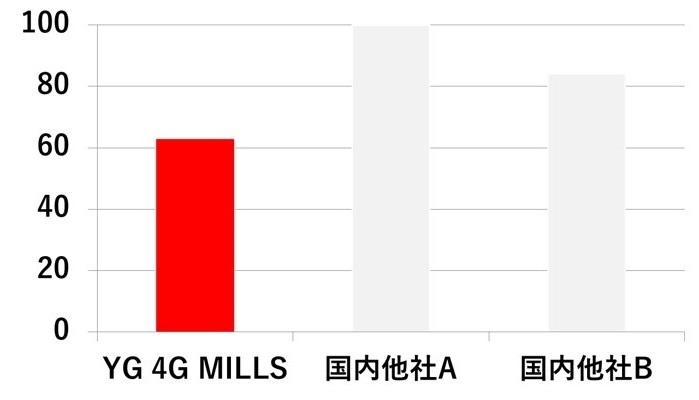

Test data

Cutting condition:Tool diameter Φ10 x 4 flute, processed approx. 20m

ap=10mm、ae=3 V=150m/min S=4,777rpm fz=0.04mm F=764mm/min

Test result: YG 4G MILLS is the least wear amount.This is suitable for high speed machining of HRC40~55 workpiece!

-

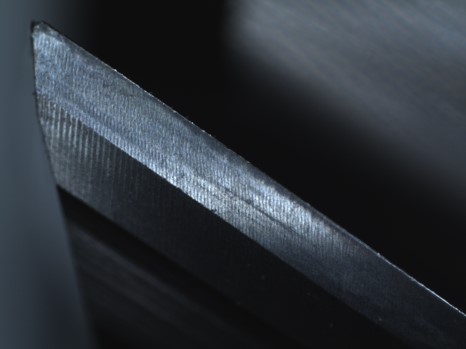

YG 4G MILLS

-

Other manufacturer endmill

Machining video

YG endmill series

-

For General Steels

NEW CENTURY -

For Stainless Steels

V7 PLUS -

For Heat Resistant Alloys

Titanox Power

-

For Pre-Hardened Steels (HRC40~55)

4G MILLS -

For High Hardened Steels (HRC50~70)

X5070 -

For Aluminum, Non-ferrous Metals

ALU-CUT

-

High speed and high efficiency machining

High speed and high efficiency machining

This excellent wear resistance allows to shorten machining time. -

Wide products lineup

Square, radius ball, and long neck are availale.

-

Regrinding and Re-coating

Supported by certified factory.