Endmill for Heat Resistant Alloy YG-1 TitaNox Power

The best choice for heat resistant alloy.

Excellent sharpness. Stable processing is possible even with heat-resistant alloys such as titanium by increased rigidity due to the adoption of a double core. This is premium series in YG-1 products.

Features

YG-1's high-end product

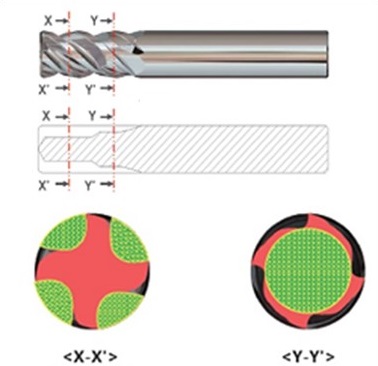

Double core endmills with excellent chip evacuation and higher rigidity.

・Excellent sharpness that cut titanium like iron

・Strengthened corner by radius

・Excellent wear resistance, heat resistant by YG-1's advanced coating technology.

Section X-X':Excellent chip evacuation

Section Y-Y':Higher rigidity

Slotting comparison

TitaNox Power vs. Other manufacturer's high performance endmill

-

TitaNox Power

Depth of cut: ap=6mm ae=6mm Cutting speed: Vc=50m/min S=2,652rpm Feed: fz=0.025mm F=265mm/min

-

Company A heat resistant endmill (Vibration occurred)

Depth of cut: ap=6mm ae=6mm Cutting speed: Vc=40m/min S=2,122rpm Feed: fz=0.03mm F=254mm/min

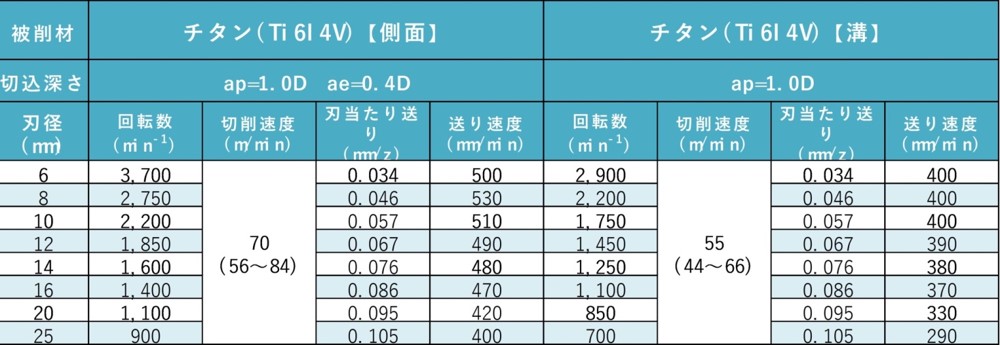

Recommended cutting condirition

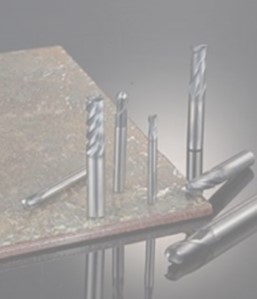

YG endmill series

-

For General Steels

NEW CENTURY -

For Stainless Steels

V7 PLUS -

For Heat Resistant Alloys

Titanox Power

-

For Pre-Hardened Steels(HRC40~55)

4G MILLS -

For High hardened Steels (HRC50~70)

X5070 -

For Aluminum, Non-ferrous Metals

ALU-CUT

Titanox power product catalogue

-

Excellent performance

Stable machining with no vibration for heat resistant alloy.

-

Regrinding and Re-coating

Supported by certified factory.