Cost improving YG-1 Flat Drills

DPP447、DPP450 Series

Flat drills with low cutting force, high chip control performance, and excellent cost performance.

We have a lineup of standard products from Φ3.0 to Φ20.0.

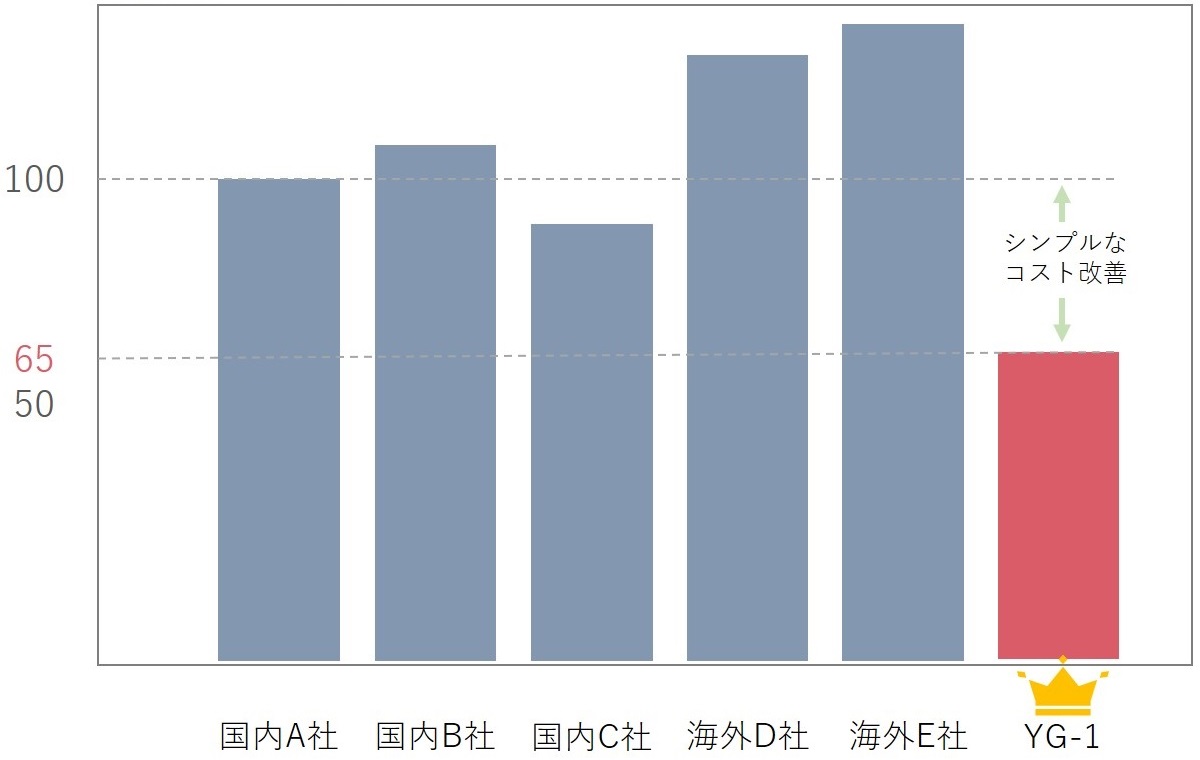

Introducing the tool life comparison results with other companies' flat drills.

Appealing point: Saving tool cost

(Comparison with Φ6 2D type without OH)

Japanese drill vs. YG-1 flat drill

Tool life comparison: machining on SCM440

-

Machine

MAZAK VCN-430A(BT40) -

Workpiece clamping condition

Workpiece material: SCM440

Size: 200mm square x 50mm height block

Vc=60m/min, f=0.1mm/rev

12mm depth, Blind hole drilling

-

Japanese other company's flat drill

2D type without OH

Actual tool diameter measurement: Φ5.008 -

YG-1 flat drill

2D type without OH

(Product code: DPP447050)

Actual tool diameter measurement: Φ5.001

Test result: After about 200 holes were drilled, there was a big difference in chip control.

Flat drills made by Japanese other companies has a chip clogging around the tool with about 1500 holes drilling.

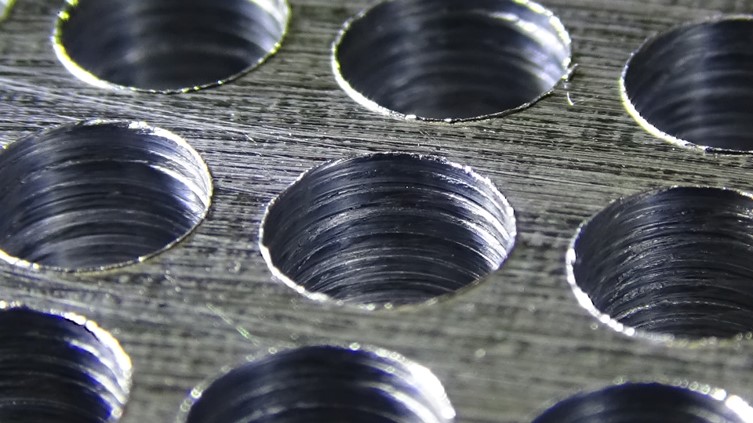

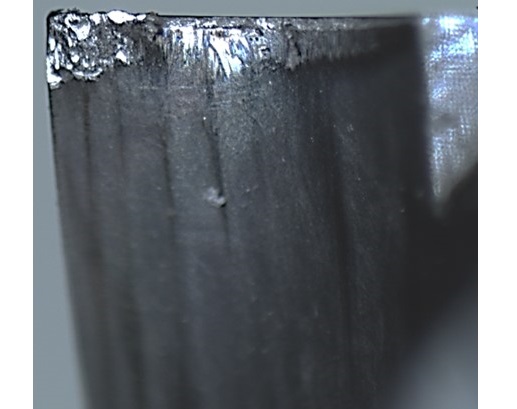

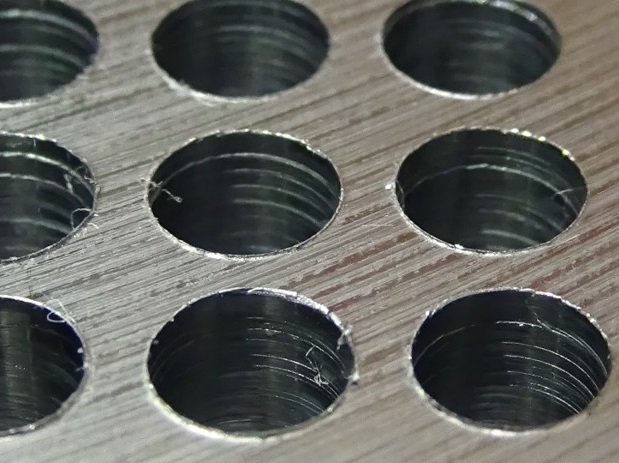

Chip clogging condition of Japanese other companies drill

During the machining of about 1500 holes, a large amount of chips clogged the tool, and it was judged that further use was not possible.

It is presumed that chip control could not be performed due to a breakage in the cutting edge.

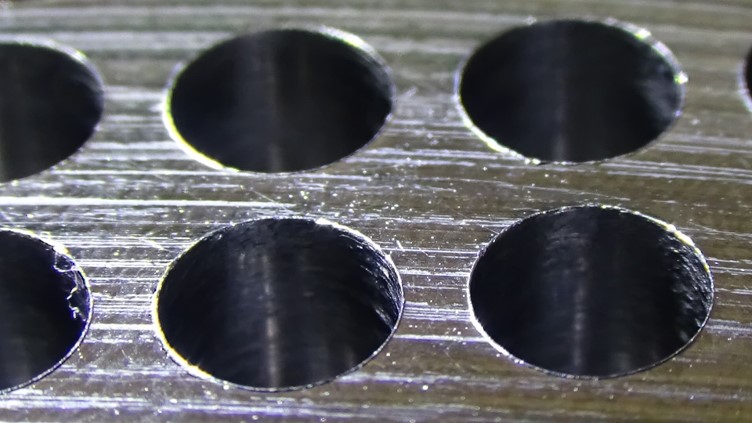

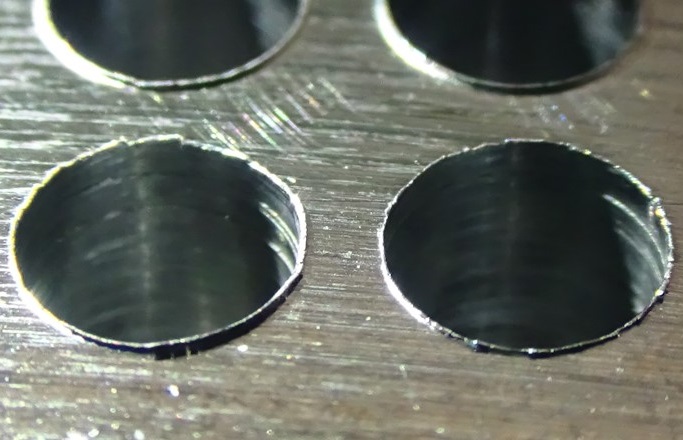

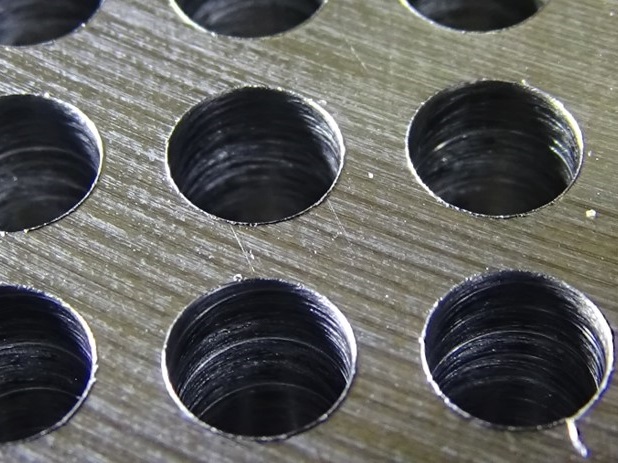

Hole comparison after 1500 holes are drilled with each flat drill

-

Japanese other companies drill: Hole diameter Φ5.109

Machining traces and burrs are conspicuous. -

YG-1 flat drill: Hole diameter Φ4.996

Less machining traces and burrs.

-

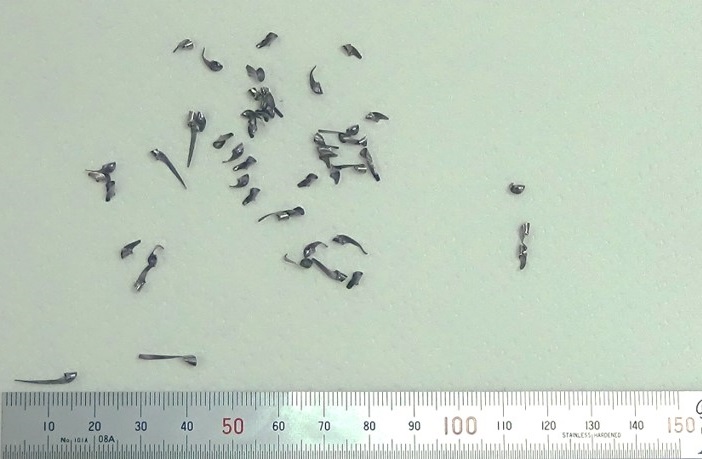

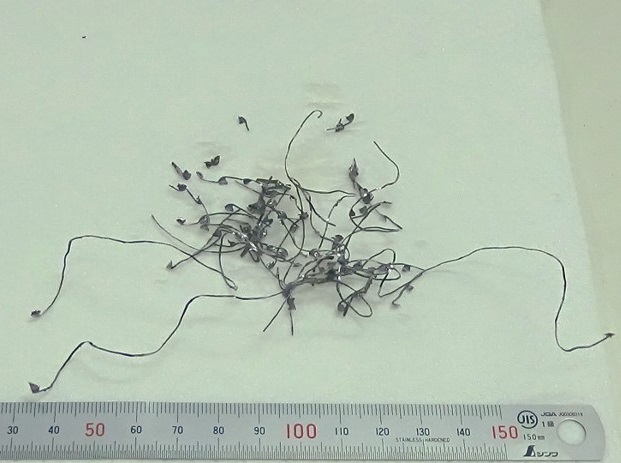

Japanese other companies flat drill:

Long chips and out of control -

YG-1 flat drill:

Cutting chips are short and able to be controlled.

-

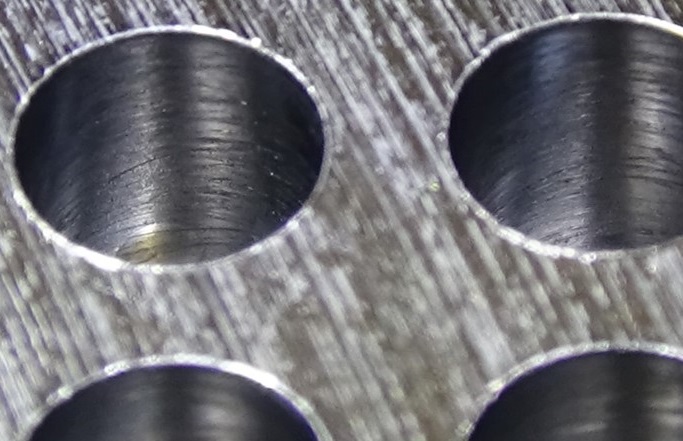

Japanese other companies drill:

The central part is largely broken. -

YG-1 flat drill:

The sholder part is damaged but machining diameter and chips have no problem.

Test progress details

After 1 to 20 holes are drilled

-

Japanese other companies flat drill:Hole diameter Φ5.018

-

YG-1 flat drill: Hole diameteΦ5.008 Machining surface is smooth.

-

Japanese other companies drill

-

YG-1 flat drill

After 200 holes are drilled

-

Japanese other companies drill:Burrs are getting produced

-

YG-1 flat drill

-

Japanese other companies drill:Chips are getting longer

-

YG-1 flat drill:No big difference

After 500 holes are drilled

-

Japanese other companies drill

-

YG-1 flat drill

-

Japanese other companies drill

-

YG-1 flat drill

After 1000 holes are drilled

-

Japanese other companies drill

-

YG-1 flat drill

-

Japanese other companies drill

-

YG-1 flat drill