Saving Cost for High Hardened Steel Machining X5070 Endmill

Endmills for high hardened steel

Endmills for high hardened steel from HRC50~70. Good performance with competitive price.Comprehensive lineup: Square, Corner Radious, Balls, and libs

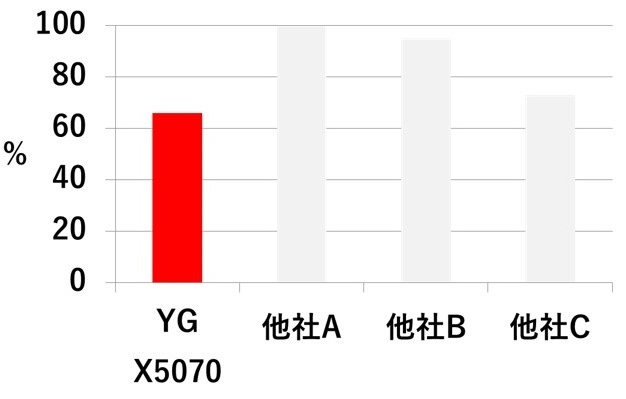

Save tool costs

Blue coated (AlTiN/Si3N4) solid carbide nano grain endmill

Excellent wear resistance, sharpness, and cost performance.Machining performance is equal to or more than other companies.

Test data

Workpiece material: HAP (HRC70)

Product code: G8D63080(Φ8.0x6 flutes)

Cutting condition: ap=12mm, ae=0.05, V=48m/min, S=1,910rpm, fz=0.03mm, F=343mm/min, DRY, machining for 58 min (approx. 20m)

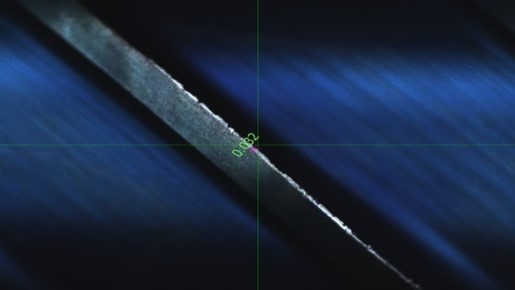

Test result: Quality of wear resistance is more than Japanese other manufacturer.

-

YG X5070

Wear amount: 0.032mm

-

Company A's endmill for high harded steel

Wear amount: 0.059mm

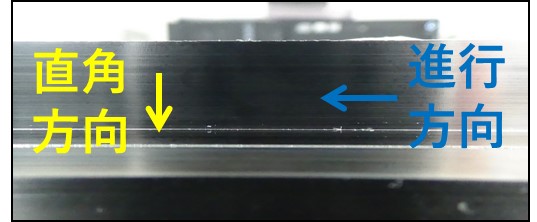

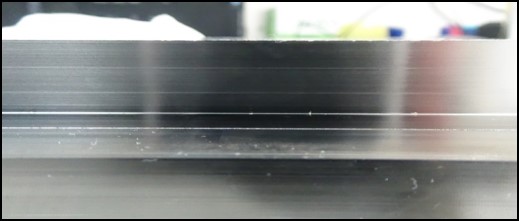

Excellent quality of surface roughness compared to tool of Japanese other manufaturer.

-

YG X5070

After 58 min machining

Vertical direction: Ra0.42

Feed direction: Ra0.17 -

Company A's endmill for high harded steel

After 58 min machining

Vertival direction: Ra0.43

Feed direction: Ra0.15

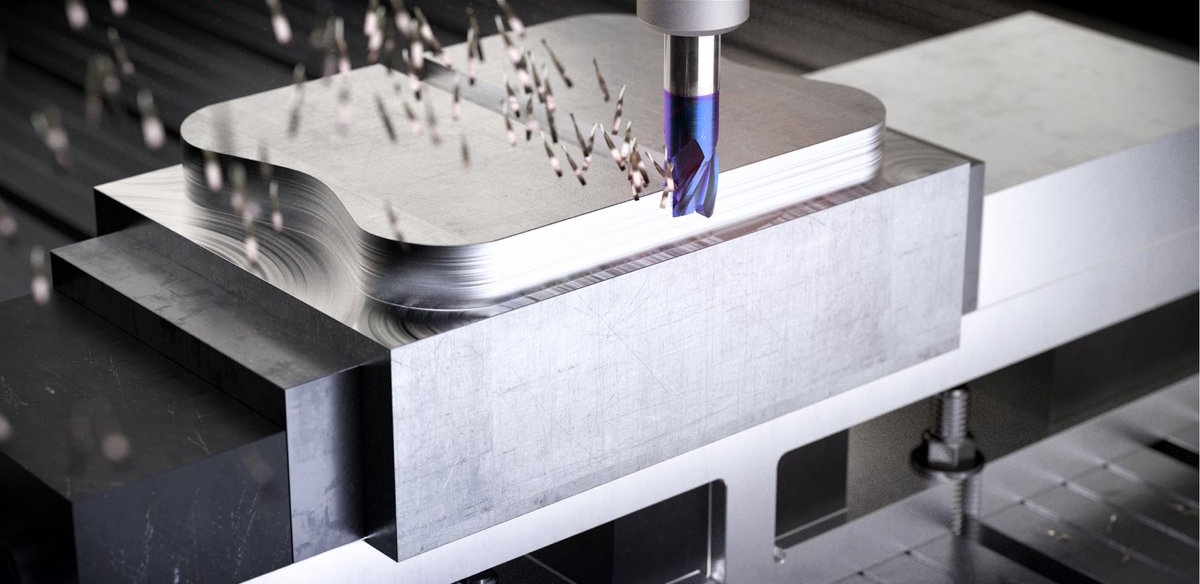

Machining video

YG endmill series

-

For General Steels

NEW CENTURY -

For Stainless Steels

V7 PLUS -

For Heat Resistant Alloys

Titanox Power

-

For Pre-Hardened Steels

4G MILLS -

For High hardened Steels (HRC50~70)

X5070 -

For Aluminum, Non-ferrous Metals

ALU-CUT

-

Saving cost

Save tool cost with better performance.

-

Regrinding and Re-coating

Supported by certified factory.

-

Recommended cutting condition

DRY.