New turning insert shape to replace DC and VB

この記事の目次

Product description

Reference: Walter youtube channel

【WALTER TURN W1011-P/WL25 COPY TURNING SYSTEM - Combines maximum stability with cost-efficiency.】

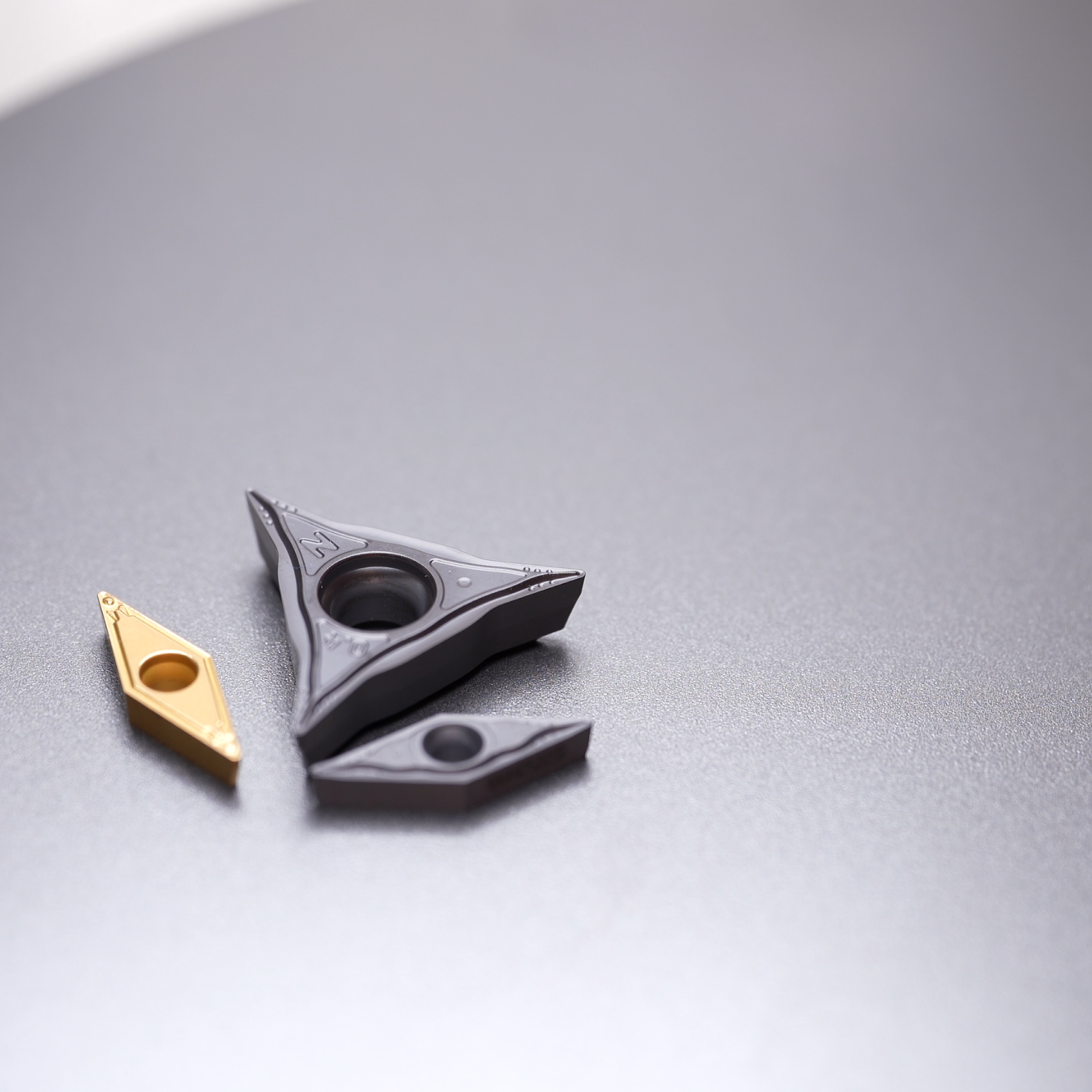

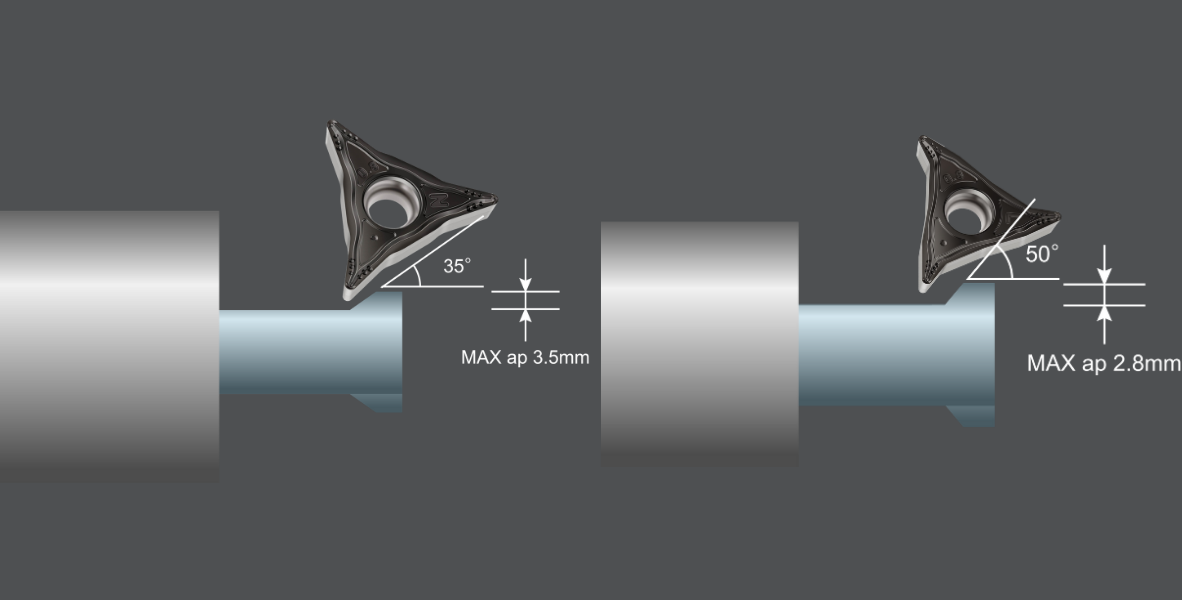

A cutting edge with a small angle has low cutting edge strength.

Tools with a small cutting edge angle, such as VB or VC inserts, have a structurally weaker contact surface than other inserts, and are easy to move due to cutting force.

Since it is a tool that is often used for finishing process, even small fractures may affect the machining quality.

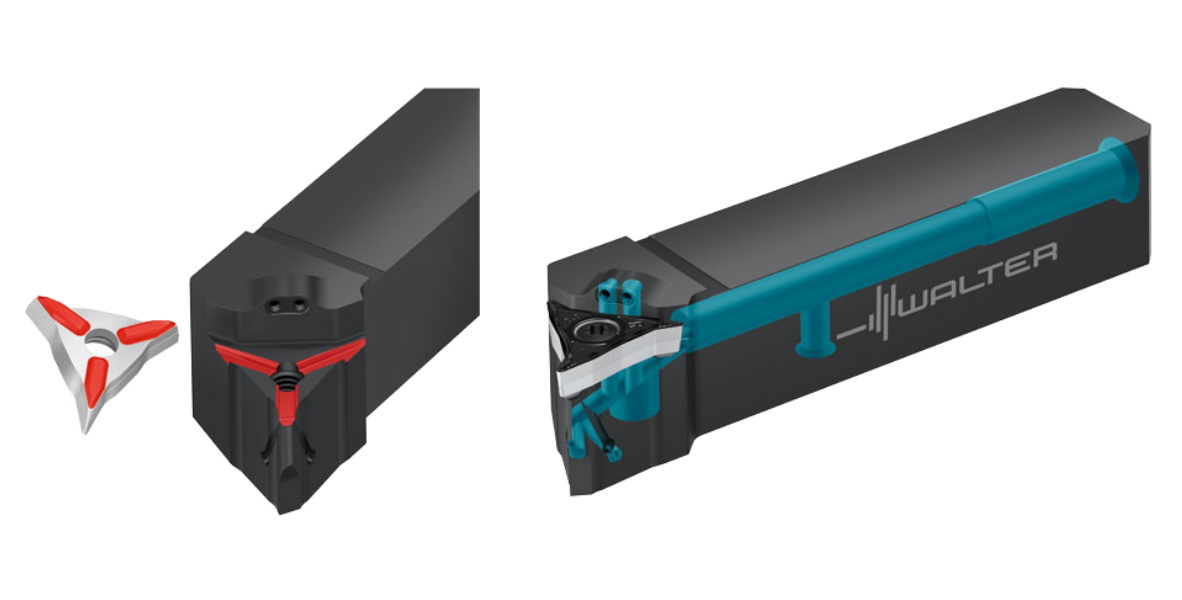

W1011 holder and WL25 insert have high rigidity due to the structure of the contact surface and holder.

The neutral type of the new product W1011 and WL25 insert has the same cutting edge angle of 35° as the V type insert.

It not only suppresses small vibration during machining, but also has high reliability against high cutting force such as intermittent machining.

The high-rigidity design achieves the recommended cutting conditions for high feed even with finish breakers.

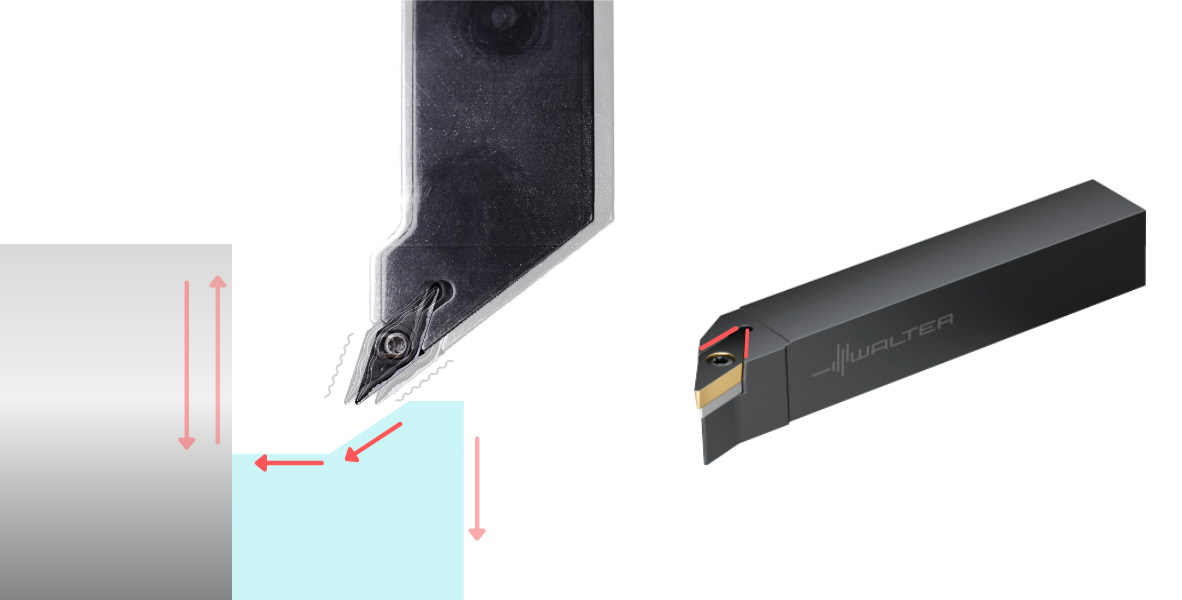

Higher feed is possible with back-turning.

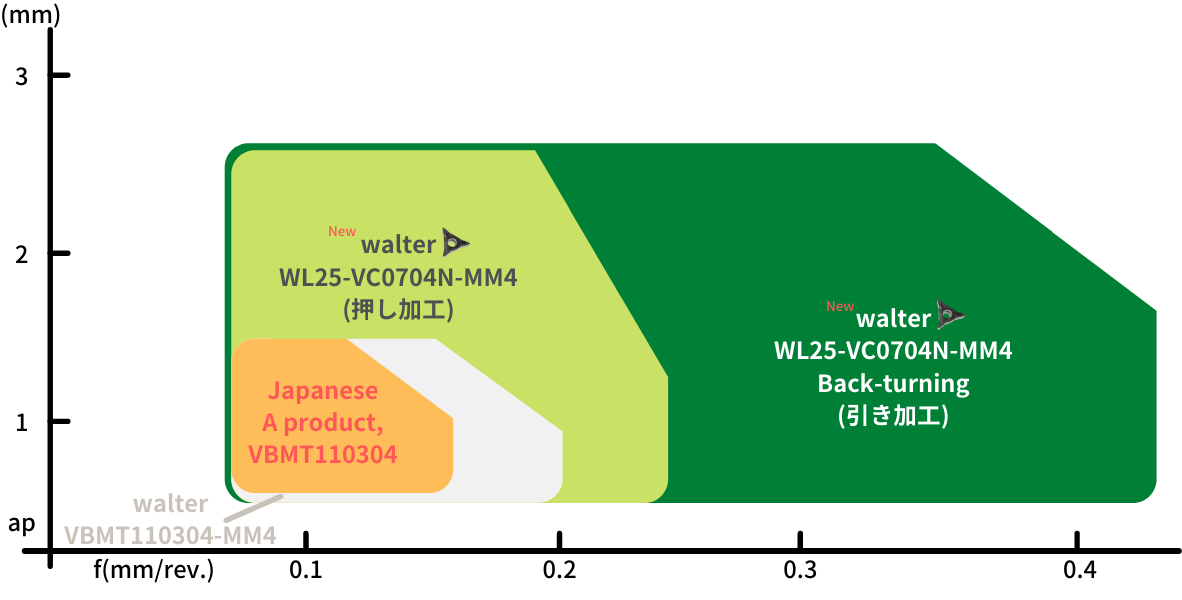

The differences from existing similar shape products

High feed is also possible with the existing similar shape but tool changing targets are CNMG or DNMG.

The unit price of those CN/DN shapes are low and have corners a lot, it is difficult to change from current one.

Also, the applicable machining environment is limited due to high cutting force.

On the other hand, the target for changing of Walter WL25-VC0704N... are VB, VC, and DCMT inserts which are relatively expensive. The tool design is also good with low depth of cutting and low feed.

The targets for changing

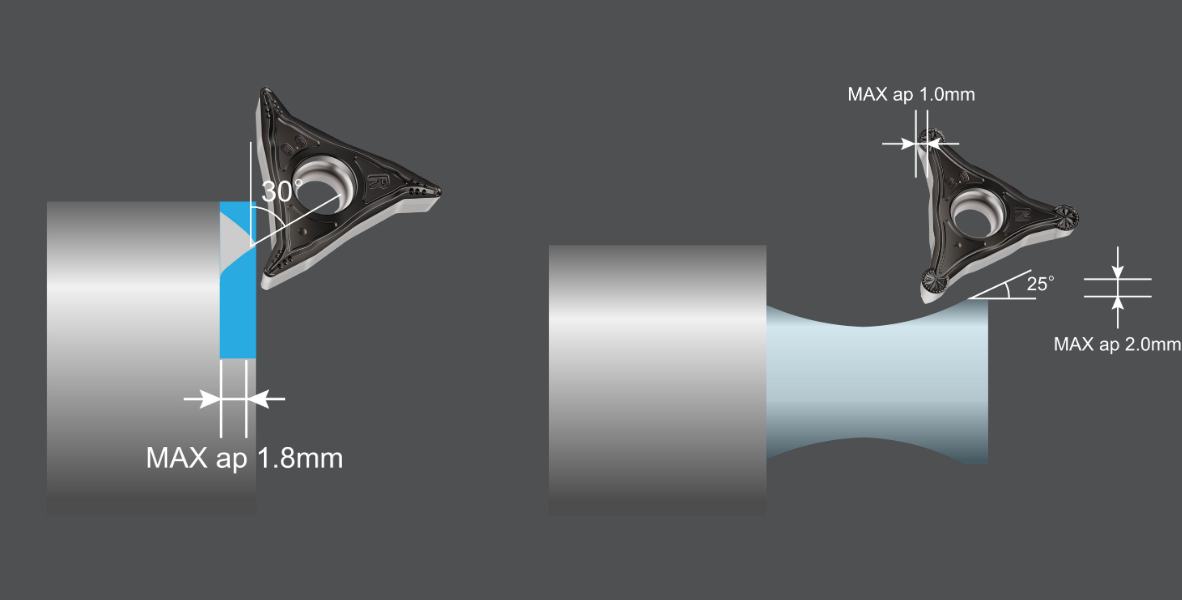

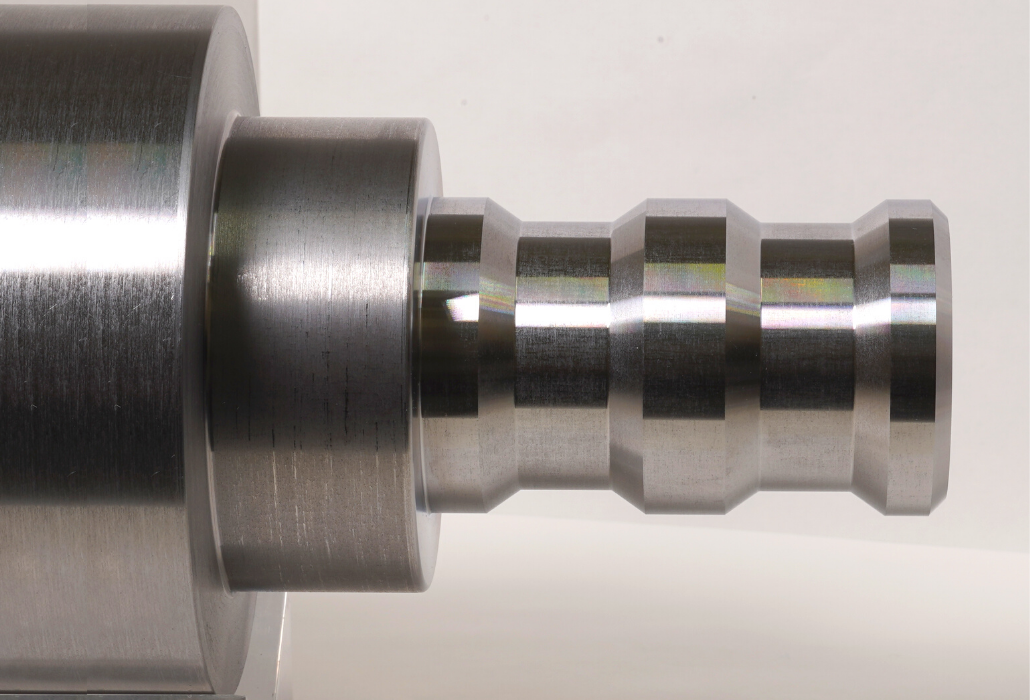

The targets for changing are external turning that requires sharpness, copying with a relief shape and recess cutting angle, and end face machining.

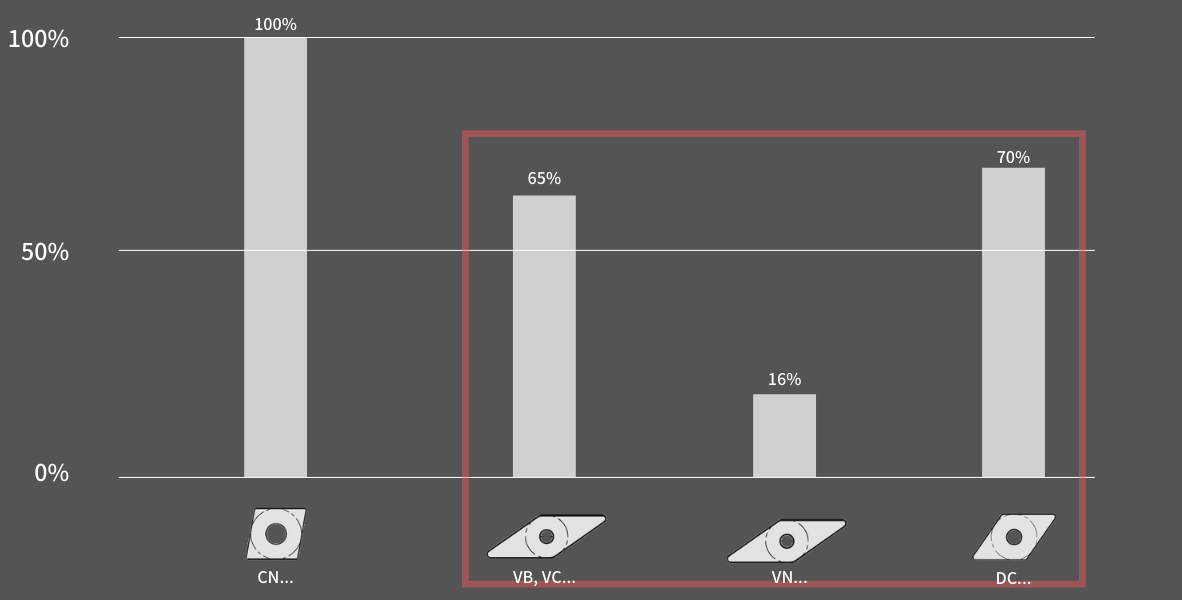

The market volume of positive cutting edge lathe inserts such as DCMT, VBMT, and VCMT is about 65 to 70 when the CN insert market is 100. (Source: WALTER, amount based)

4 different types of inserts can be used in the same holder.

Test report

-

Machine

Mazak QT-compact200MY -

Workpiece material :S50C

Workpiece size : Φ90 x 200mm length

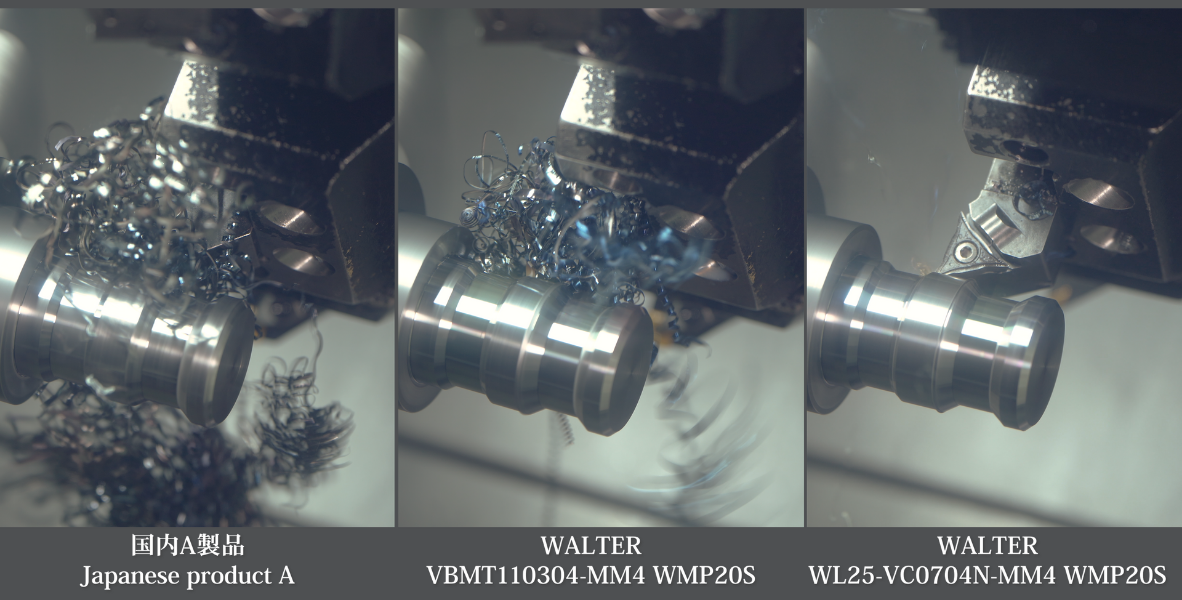

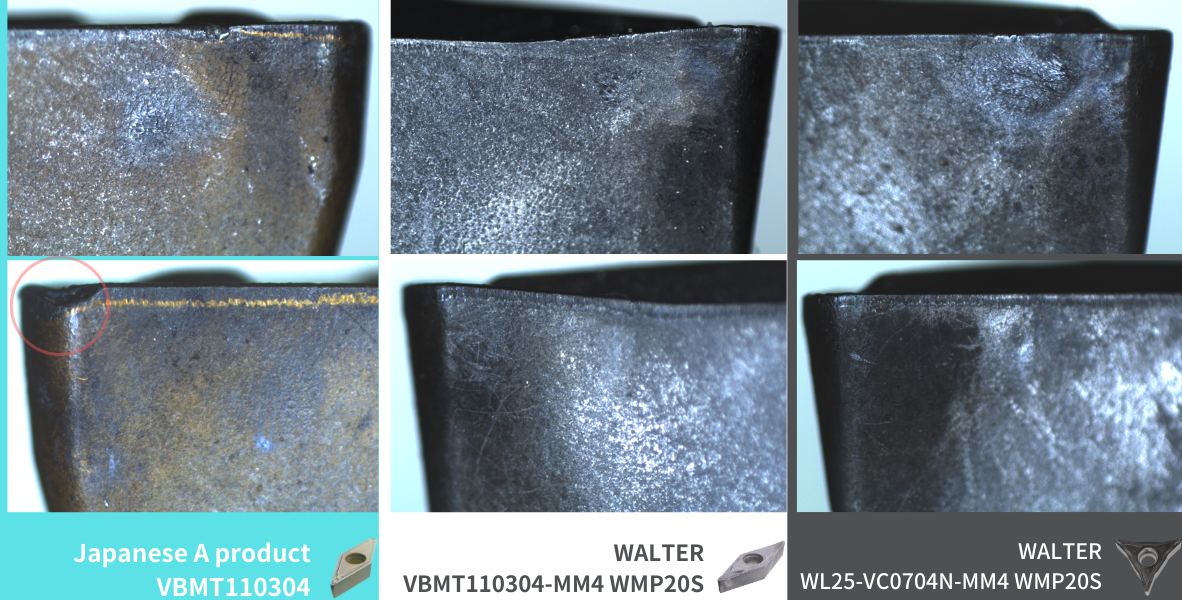

Chip control performance / Comparison of finishing surface on the workpiece

Vc=170m/min, ap=1mm & 0.3mm f=0.08mm/rev.

A machining test with the lower limit of the recommended feed conditions for Japanese company A's product and Walter BMT110304-MM4.

Breakers and materials are for medium finishing to finishing, but VBMT products could not control chips properly.

WL25 insert had good chip control in all processes of turning back-turning, recess cutting, and end face back-turning.

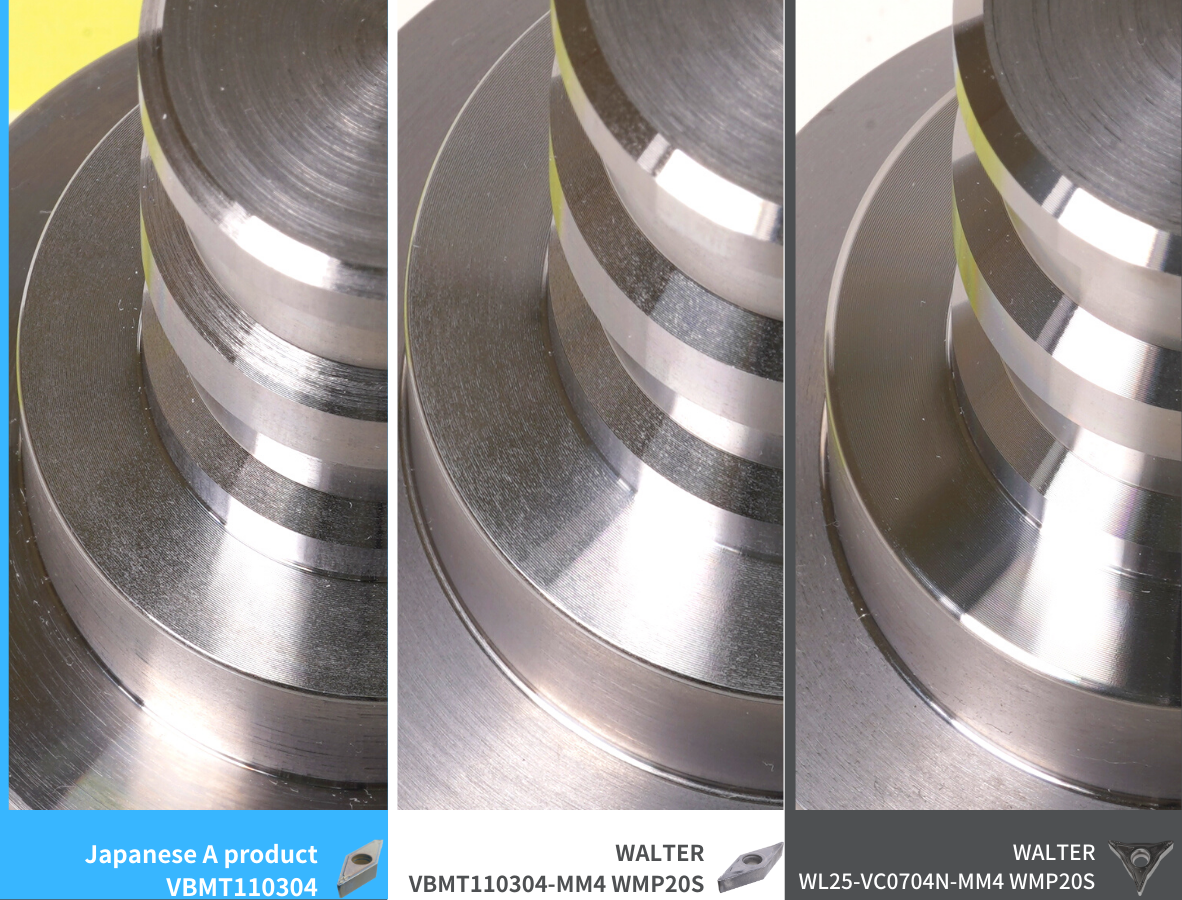

Cloudiness is remarkable on the end face of the workpiece processed with VBMT, but the surface is shiny processed with Walter WL25.

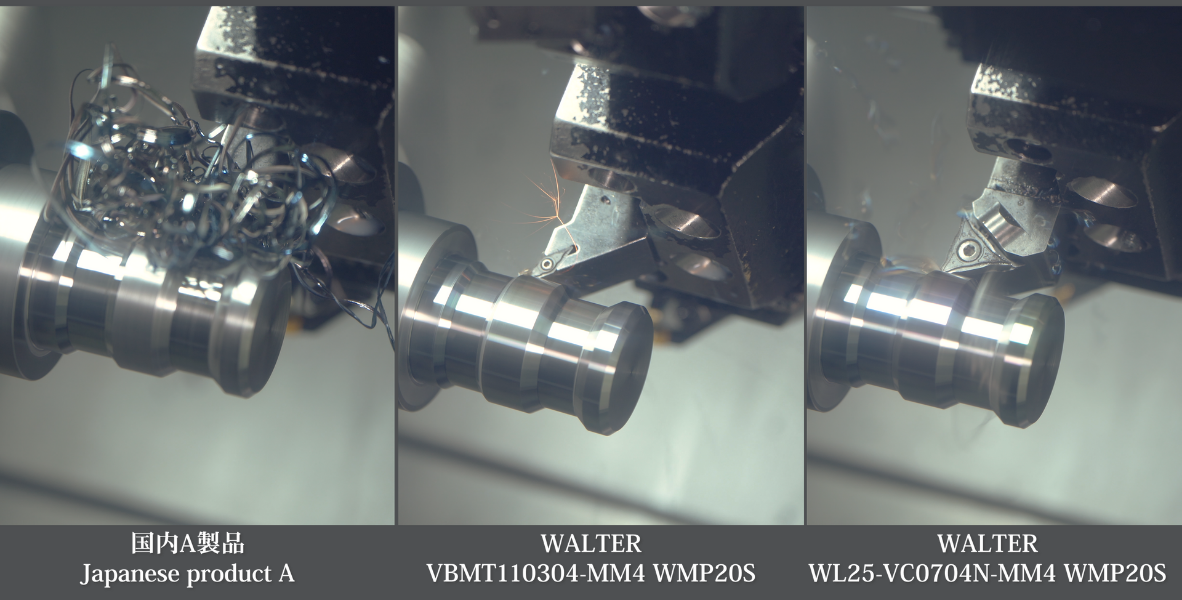

Chip control performance / Comparison of finishing surface on the workpiece

Vc=170m/min, ap=1mm & 0.3mm f=0.16mm/rev.

A comparison test with the recommended upper limit of feed of Japanese company A's products. (f=0.16)

The chip control of Japanese company A's product did not improve even if it was raised to the upper limit of the recommended value.

WL25 has good results even under this condition.

Galling and scratch mark are worsened at recess cutting by Japanese company A's product.

On the other hand, the surface is shinier by Walter WL25.

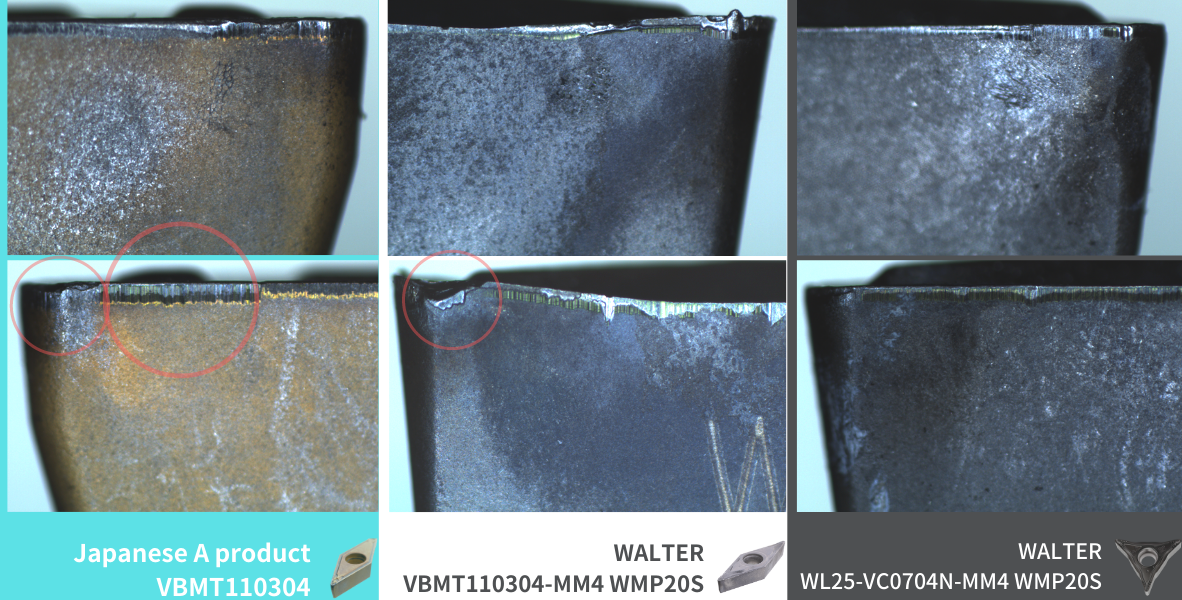

Durability test

Vc=110m/min, f=0.11mm/rev, ap=1mm After machining for 300 min (5 hours)

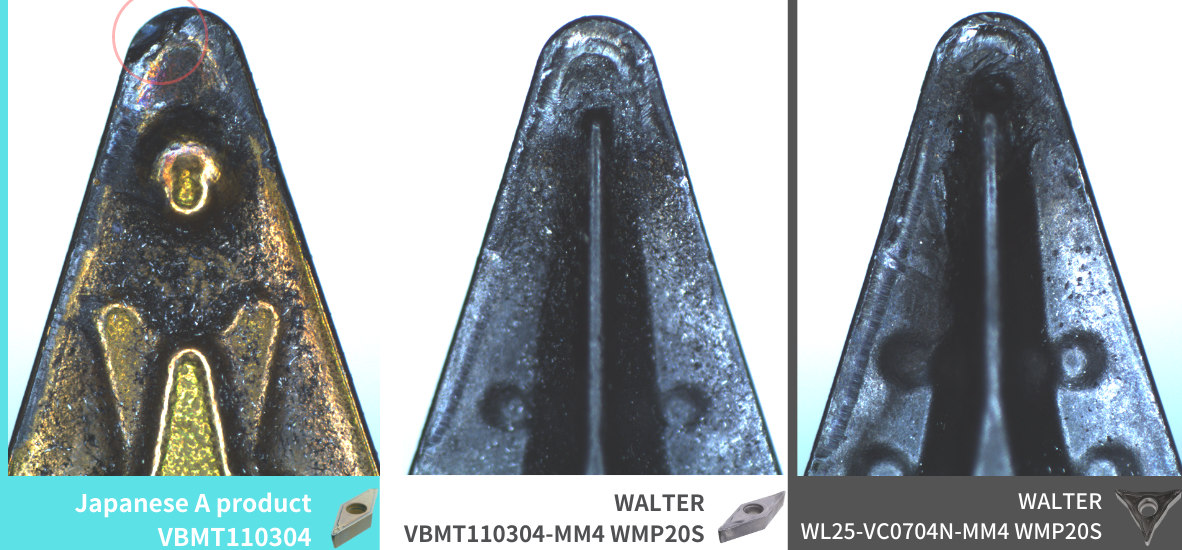

Upper: Push-turning side / Lower: Back-turning side

VBMT has a large amount of wear on the cutting edge on push-turning process side, and defects occur on the back-turning process side.

Vc=230m/min, f=0.16mm/rev, ap=1mm After machining for 100 min

Upper: Push-turning side / Lower: Back-turning side

A small fracture occurred on the turning side of the Japanese company A's product, and a tool breakage occurred on the cutting edge on the back-turning side. Walter's products did not change at this amount of machining.

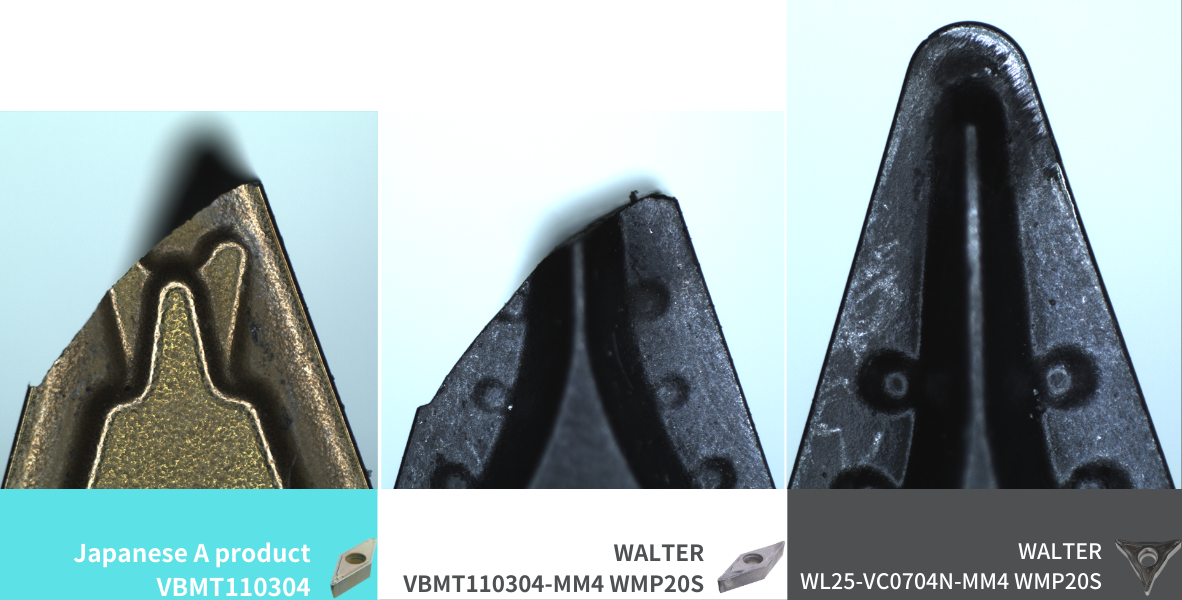

Testing with intermittent workpiece

Vc=130m/min, f=0.12mm/rev. ap=1mm

VB insert was damaged in a few passes due to the strength of the cutting edge and the clamp rigidity of the insert.

The images below: (from left) 1st pass by Japanese company A's product, 3rd pass by Walter VBMT, after machining for 30 minutes or more by Walter WL25

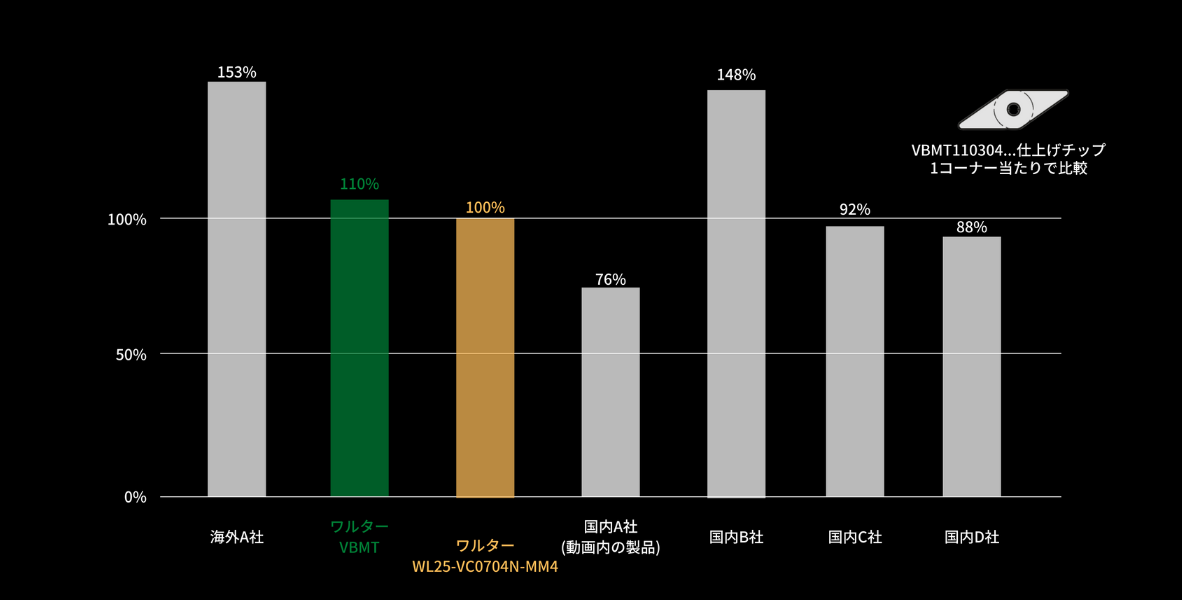

Price comparison

Price comparison graph with VBMT1103 type when WL25-VC0704N ... is set to 100.

There is a possibility that further cost benefits can be expected compared to VB and VCMT16 size.

(from left, Overseas A product, walter VBMT, walter WL25, Japanese A, B, C, D product)

Summary video of this article

Serious ver.

Parody ver.

We asked question to Sales engineer