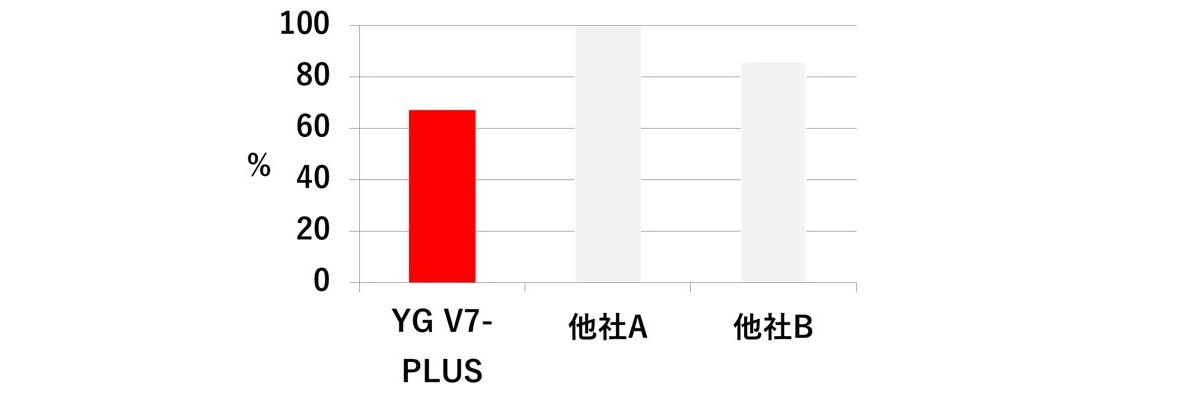

Saving Cost of Steel and Stainless Machining V7 PLUS End mill

High Cost Performance Endmill for Stainless Steel.

Excellent sharpness on stainless steels machineing.

Excellent performance with inexpensive price.

Save tool costs

※Price comparison : company A is taken as 100.(each tools are for stainless steel)

Optimum Edge for Stainless Steel Machining

Reduce vibration by variable leads and pitch.

Competitive price to other endmill for stainless steel.

Test data

Workpiece material: SUS304

Product code: GMF56100 (Φ10x4 flutes)

Cutting condition: ap=15mm, ae=2mm, V=80m/min, S=2,547rpm, fz=0.03mm, F=305mm/min

Test result: V7-PLUS has the best sharpness judging by surface roughness and burrs.

-

YG V7-PLUS

Smooth surface with less burrs.

-

Company A

Surface is almost the same but more burrs.

-

Company B

Rough surface by vibration at starting.

Video

YG endmill series

-

For General Steels

NEW CENTURY -

For Stainless Steels

V7 PLUS -

For Heat Resistant Alloys

Titanox Power

-

For Pre-Hardened Steels

4G MILLS -

For High hardened Steels (HRC50~70)

X5070 -

For Aluminum, Non-ferrous Metals

ALU-CUT

-

Saving costs

Tool cost improvement for stainless steel and titanium.

-

Regrinding and Re-coating

Supported by certified factory.