High feed cutters carrying tangentially clamped rhombic inserts

Unique design high feed cutter

Product code: FFV-DR-VN077

V type two-face contact

×

Tangential high feed

Here are comparison tests with SOMT and LNMU.

Videos

-

Concept video

Strong dovetailed insert clamping

-

Machining test

How is the performance difference by different insert shape?

Performance comparison: Face milling, Shoulder Milling, and Helical coutouring milling

-

Machine

Okuma Corporation MA550VB

BT50 vertical machining center -

Workpiece clamping condition

Workpiece size: 200x200mm, block

Workpiece material: SCM440、SUS304

-

TANG4FEED

Insert design: VNMTCutter lead angle: 16°

Maximum ramping angle: 2.2°

Maximum depth of cut: 1.5mm -

Other manufacturer's high feed cutter A

Insert design: SOMTCutter lead angle: 1°

Maximum ramping angle: 2.0°

Maximum depth of cut: 1.5mm -

Other manufacturer's high feed cutter B

Insert design: LNMUCutter lead angle: 16°

Maximum ramping angle: 0.6°

Maximum depth of cut: 1.5mm

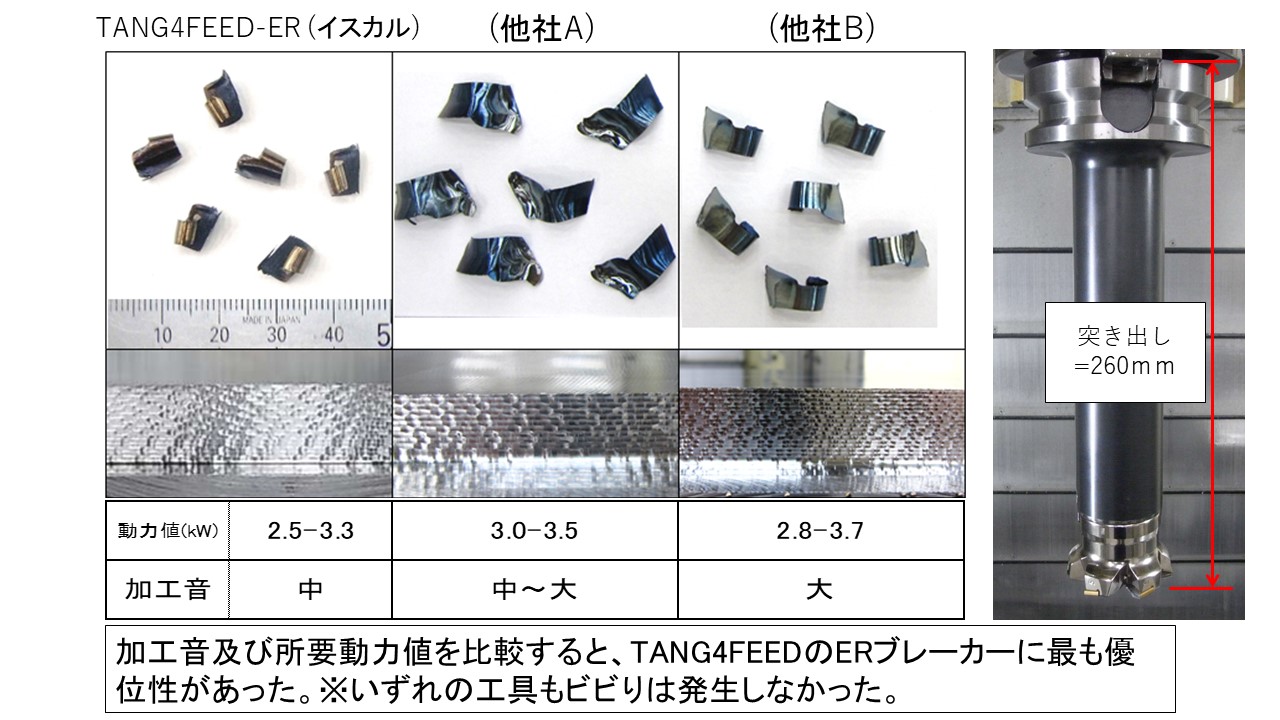

Face milling test result

Chips of TANG4FEED are shorter compared to other tools.

SCM440 (Vc=120m/min、fz=1.0mm/t、ap=1.0mm、ae=45mm)

SUS304 (Vc=120m/min、fz=1.0mm/t、ap=1.0mm、ae=45mm)

Shoulder milling test result:Compared to other tool, machining sound volume of TANG4FEED is smaller and cutting power is also lower.

SCM440 (Vc=120m/min、fz=1.0mm/t、ap=1.0mm、ae=20mm、Overhang=260mm)

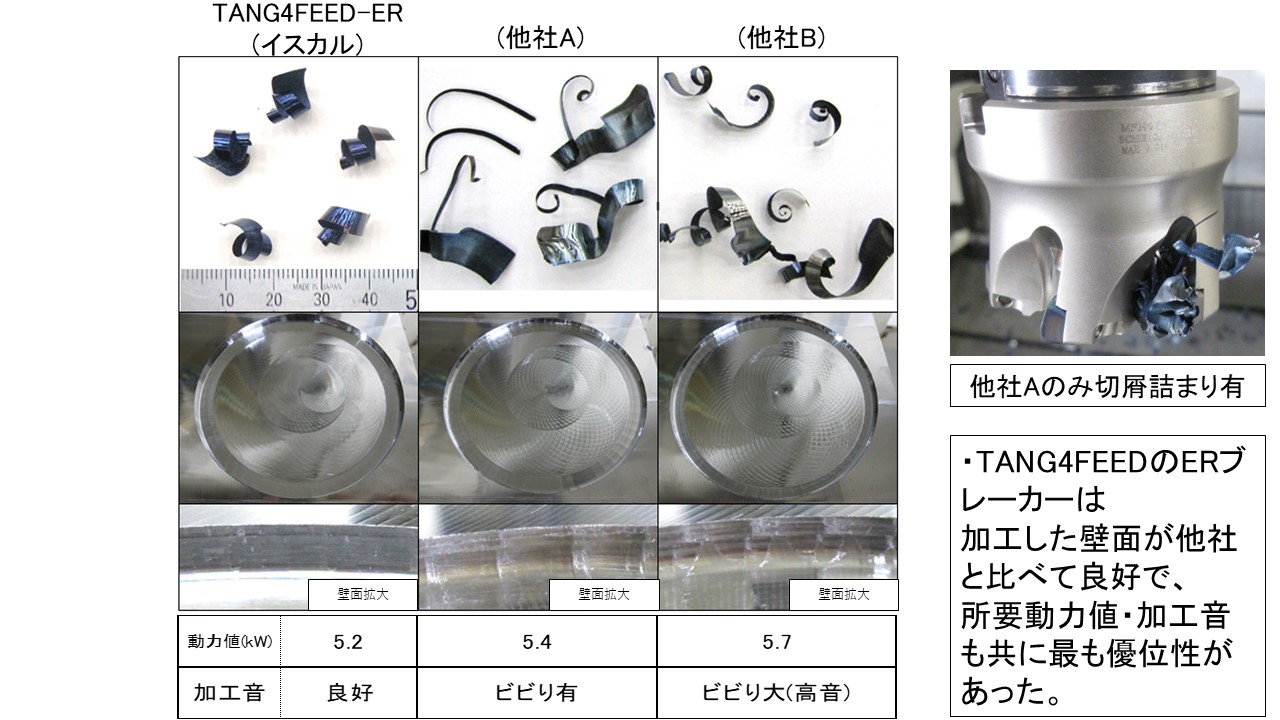

Helical coutouring milling test result:

Helical coutouring milling test resultTANG4FEED has high surface quality.

Machining sound volume is smaller compared to other tools.

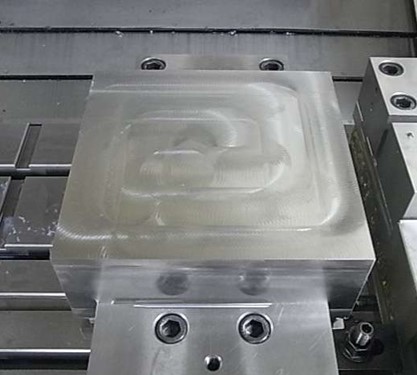

SCM440 (Vc=120m/min、fz=1.0mm/t、

Pitch=1.0mm[Ramp down angle:0.4゜]、Overhang=260mm)

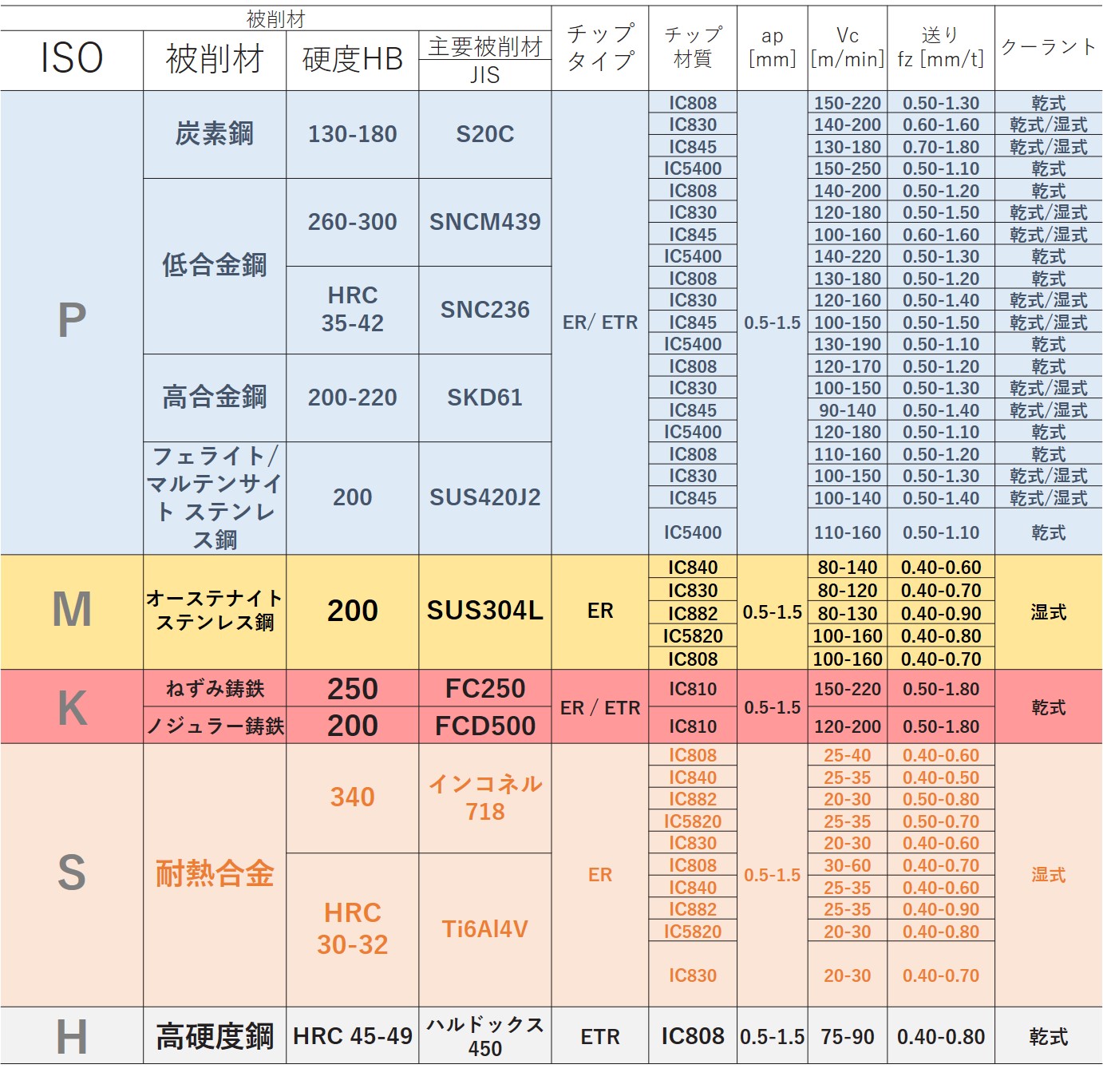

Recommended cutting condition

Appealing sales points and object candidates of changing

VOMT insert

https://www.iscar.com/Ecatalog/Family.aspx?fnum=3907&mapp=ML&app=75&GFSTYP=M&fr=1&rcat=3312129&item2=&ssOrder=&loc=&IC=

FFV-D-R-VN07 holder:

https://www.iscar.com/Ecatalog/Family.aspx?fnum=3906&mapp=ML&app=75&GFSTYP=M&fr=1

-

New design insert

Large lapping angle is available by new insert design.

-

Strong dovetailed insert clamping

Stable machining by strong dovetailed insert clamping even at large cutting force.

-

Recommended machine

Since insert corner areas are large design, machine rigidity and workpiece rigidity are necessary.