Cominix tool layout service

Selecting an optimal product and a manufacturer just one-stop.

Do you have many meetings with manufacturer when considering the tools for new project?

COMINIX provides one-stop layout for new tools.

Assumed case: Selecting the tools for new project

Disadvantages of conventional case

In case of having meetings with many manufacturer to compare the prices:

Have you ever been concerned that you couldn't manage the progress because you had many meetings, or that it took a long time to check each items and you couldn't have enough time?

Also, after making special tools, have you ever found it on other company catalog as standard products?

We can solve such a problems.

Advantages of selecting Cominix

Please give us some details.

We will provide one-stop service to select optimal tools.

Please give us some information about workpiece, machine, leadtime and your requirement.

Examples of customer requests

・Select a standard product as much as possible

・Reduce machining time by using special tools

・educe initial cost as much as possible

・Want to use excellent performance tools ... and so on

We will select optimal tools from various manufacturers by our knowledge and experiences.

We will suggest suitable tools and cutting conditions from 10 Japanese manufacturers and 20 overseas manufacturers based on customer request.

Examples of manufacturers

mall diameter drills and endmills :AXIS

Threading tools :VARGUS

Chamfering tools and Centering drills:MAGAFOR

Tools for automatic lathe :UTILIS

... and so on

We have plenty of inventory.

Over 100 thousand inventories make you feel safe in case of emergency. We have wide tool inventories both Japanese manufacturers' and overseas manufacturers'.

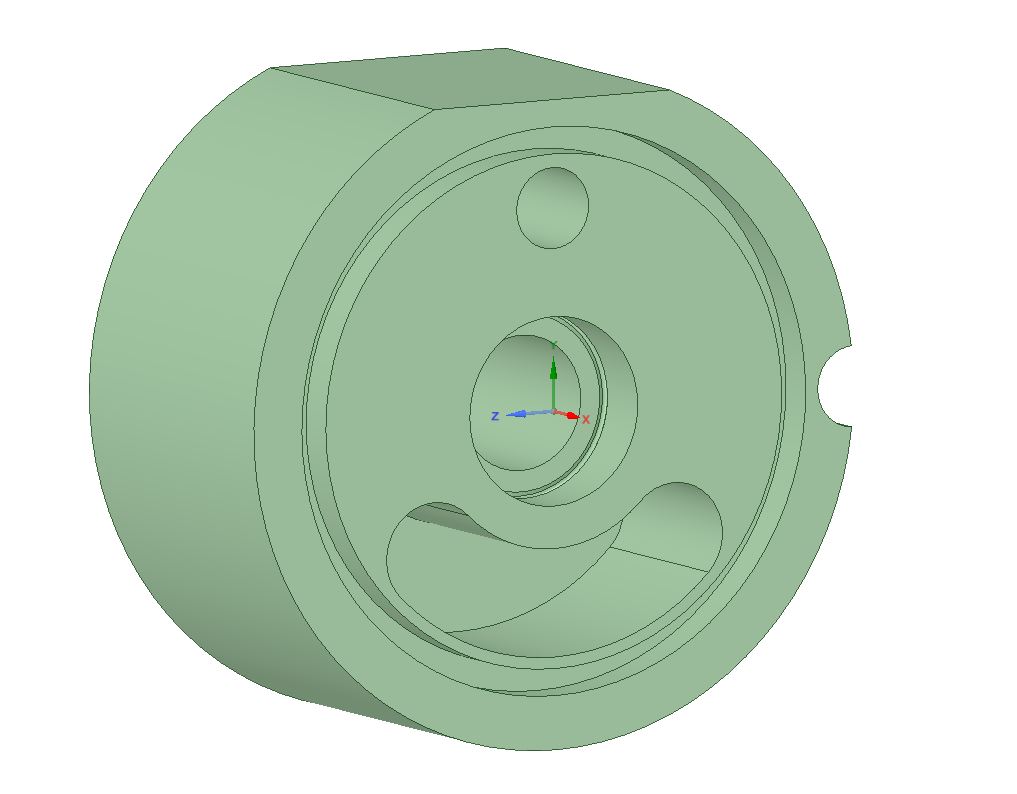

Cost estimating of tools with tentative workpiece

Tentative workpiece

Grade: SCM420

Machine: 5-axis machine by Mazak (Capto6)

Enternal diameter machining, end-facing

Cernter hole drilling

Internal diameter machining

Boring bar for special recessing

Face grooving

Flat slotted drill

Slotted endmill

Flat drill for eccentric hole

Small diameter drill

Threading (Threading endmill)

Flat cutting (Indexable endmill)

End mill for half moon machining

Inverse facing insert

Turning holder

15 pcs of various toolings

Insert is 10 pcs each. Drill, end mill, and holder is 1 pc each.

Total cost: 448,520 JPY (Leadtime: 20 days)

If consider with Japanese manufacturer A, Japanese manufacturer B, overseas manufacturer C, and overseas manufacturer D.

Total cost: 774,945 JPY (Leadtime: 70 days~)

Why Cominix can suggest such cost and short leadtime?

-

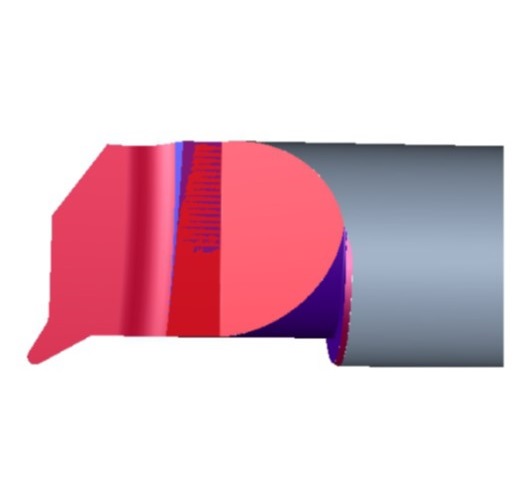

Special tool made by Nishiken Boring bar for special recessing

Leadtime for coated tool is about 20 days. Available from just 1 pc. -

New century

Even extra long 4 flute 5D drills are standard product. High-versatility and good cost performance. -

YG-1 flat drills

Excellent sharpness and good cost performance

How about folowing tools if the grade of workpieces are stainless steel or difficult-to-cut material?

-

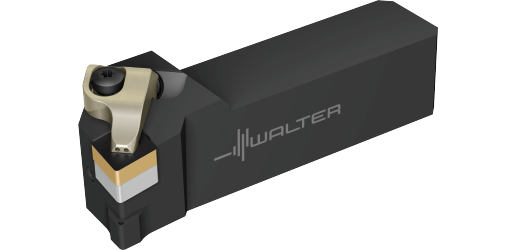

Walter: Insert holder with coolant to the edge

Double clamping and coolant to the edge make you feel safe.

-

Walter: Grooving tools with internal coolant

There is no holder body under the insert, no restriction of maximum diameter for face grooving.

Walter: C6 insert adapter for external turning holder

Internal coolant is available without hose.