Efficient changing of milling tools for lathes

The quick change system Varia

It is available for nearly all tool holders.

A tool change will just take short time!

Reducing the set-up time and increasing the productivity!

Tool change "without" the quick change system

The tool is replaced using a spanner in the machine, it may be difficult to replace the tool if the inside of the machine is too narrow or too far from the changing tool position.

Since the machine will stop during the tool change, productivity will change depending on workability.

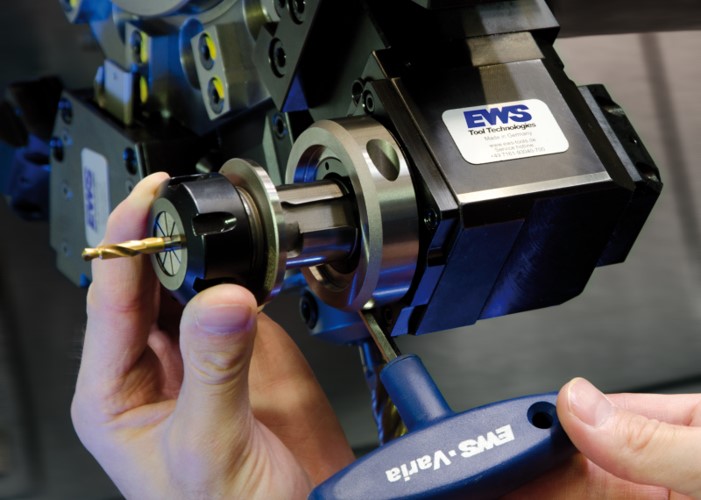

Tool change with the EWS Varia

Preset cutting tools outside of the machine in advance

Tools can be attached to the head in advance outside the machine.

* There is a fit-up aid to change the tool outside the machine.

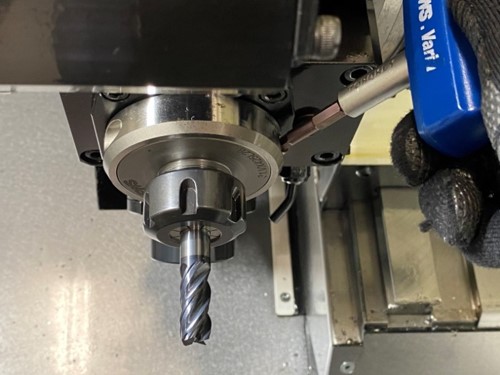

Simple and quick change the tools.

Quick change through only one clamping point.

Changing time is less than half that of the usual method.

Usual tool changing vs. EWS quick change system

No loose parts!

Machining test result with EWS quick change system: Smooth surface without vibration

Workpiece material: S45C

Tool: 3 flute indexable cutter (Φ20)

Machine: QT-COMPACT200MY(MAZAK NC lathe)

Cutting condition:

Tool change and machining video

Machining starts from 29 sec~Various heads for various tools.

-

ER collet chuck

-

Weldon / Whistle notch insert

-

Shell mill holder