Process Monitoring and Prevention of Tool Breakage from Improper Parameter

KOMET®Tool scope

Monitoring, analyzing, and recording system for cutting force.

There are supporting applications and one of app. it can detect collision.

Modular cutting force monitoring system

It is attached to communication sysytem at machine and keep monitoring cutting force.

The difference from the measurement system by measuring the cutting force of X, Y, Z axis.

Collect, store, record the data in real time regardless of the size and shape of the jig / work.

Tool scope applications

-

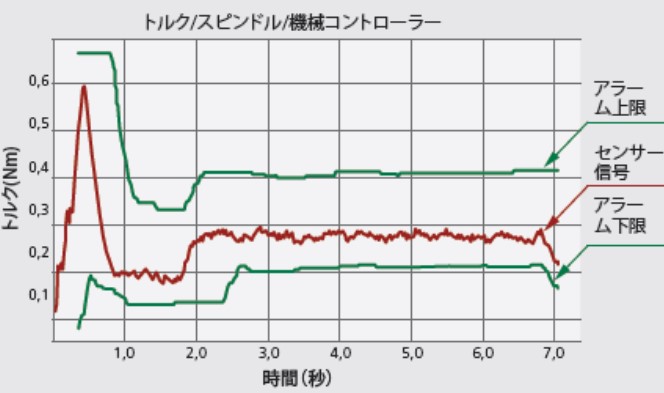

TS-PM app

Adjust maximum and minimum torque by tool and machining monitoring.

-

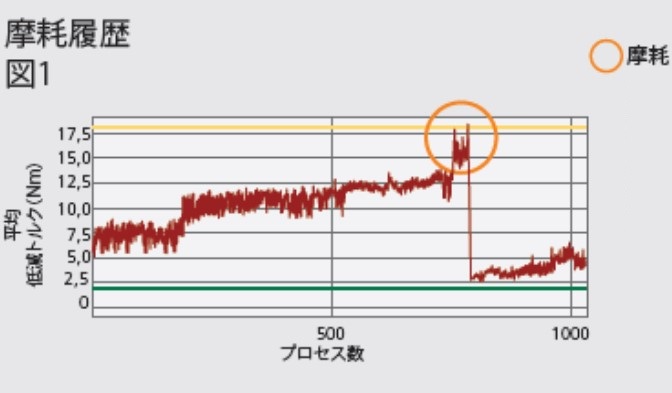

TS-WEAR app

Optimize tool life by monitoring torque changes.

-

TS-AFC app

Variation of feed override in dependence of torque load at the spindle.

-

TS-Cloud app

All data is automatically stored and enable to check.

-

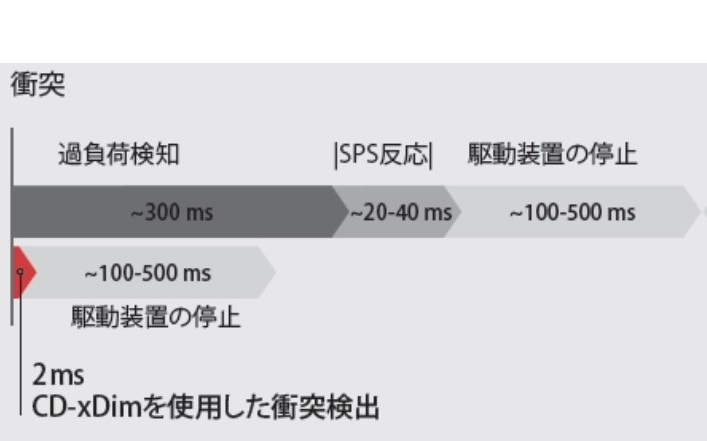

CD-xDim app

Monitoring a collision to prevent a collision occurs.

-

TS-TCLog app

Automatically logging tool change

-

TS-CM app

Always monitoring machining condition.

-

Application functions

-

TS-PM app

Self-learning process monitoring with statistical-based tolerance limits. (patented 6-Sigma method)

In case of abnormal status such as machining load is too high or too low, processing will be stopped. -

TS-WEAR app

Monitoring of torque changing to judge optimal tool life. Optimize tool change timing by the data.

-

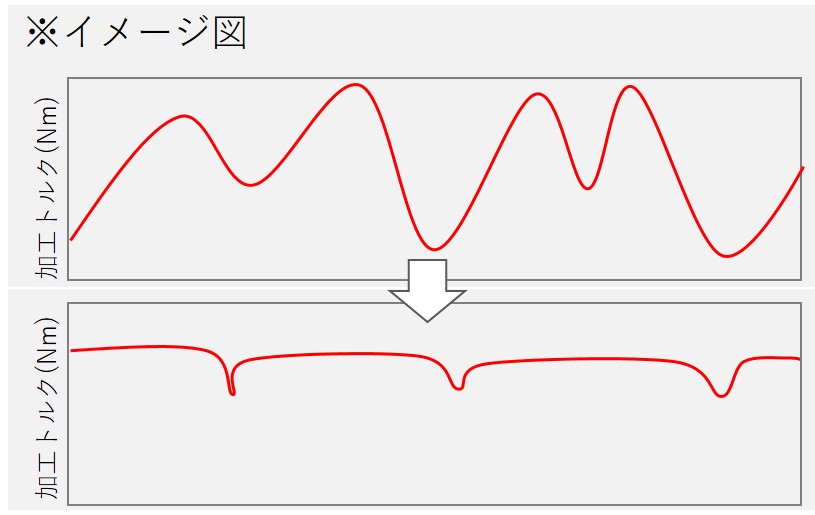

TS-AFC app

Automatically adjust feed to make cutting force uniformize by self-learning.

It is effective for interrupted machining of rough cutting since feed is optimized by each cutting force. Recommended for improving machining efficiency and extending tool life. -

CD-xDim app

Detecting collision 150 times faster compared to conventional system.

Minimize spindle damege by sending stop signal from tool scope.

Further product detail

https://www.toolscope.de/fileadmin/user_upload/9_downloads/informationen/toolscope/JP_ToolScope-Assistance-system.pdf

and attention

-

Improve machining based on data

Visualizing process improvement based on actual data.

-

Minimize problem

Detecting tool damage by adjusting maximum and minimum torque. Monitoring collision in case.

-

Technical service

Operation and maintenance services by technical sales and technicians.

-

Not recommended for micro machining and low cutting force machining

It may be difficult to properly detect resistance depending on the processing conditions