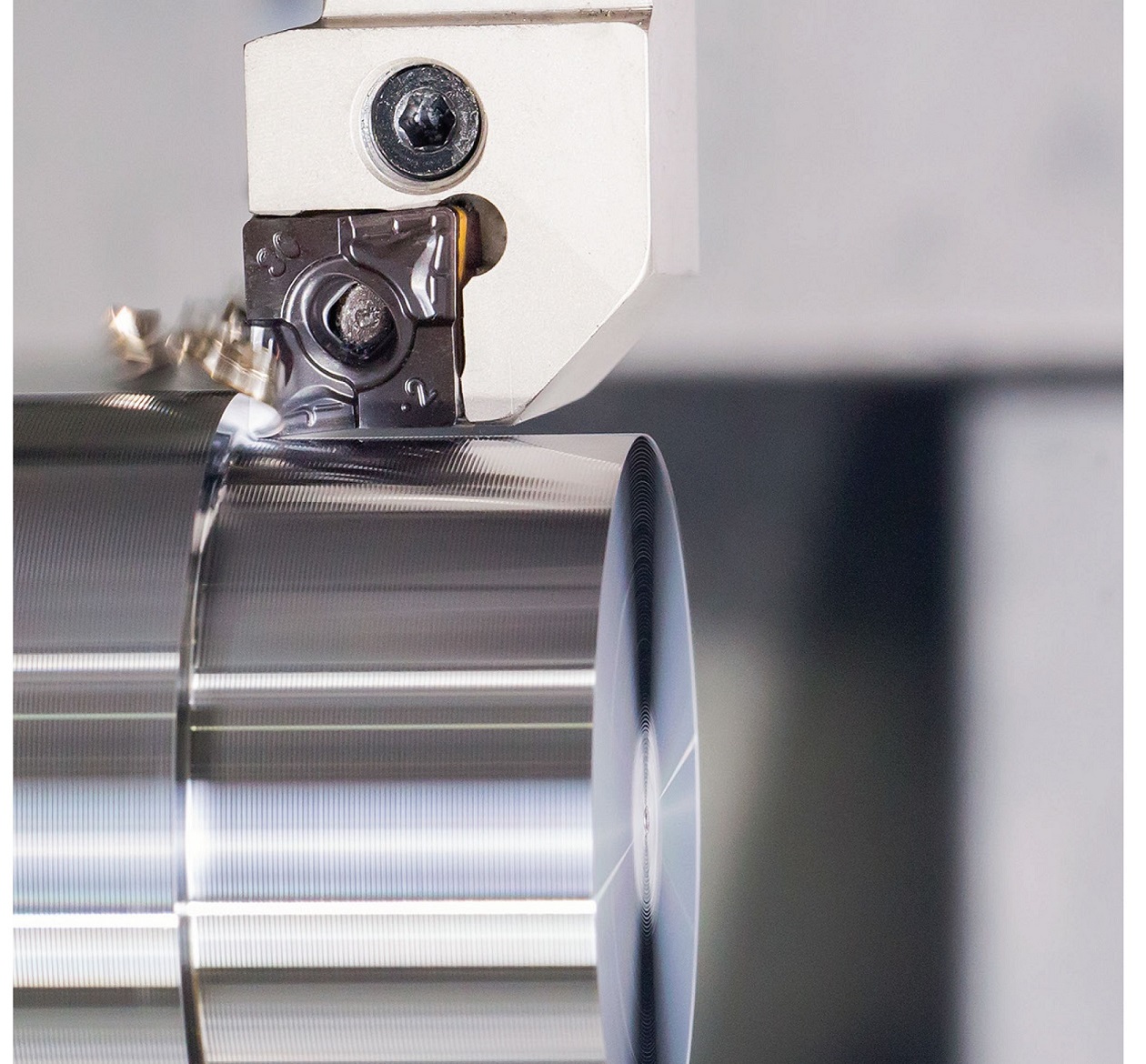

New Design Turning Insert Excellent rigidity, sharpness, and economical.

LOGIQ4TURN CXMG

CXMG is double sided insert with 4 cutting edges. It is possible to save cost if changing from CCMT insert.

A dove-tailed pocket design for very firm insert clamping.

It is available with finishing machining of alloy steel and stainless steel.

Low cutting force to eliminate built-up-edge.

Product concept

-

New design CXMG insert

4 cutting edges with flank angle

-

Conventional insert with 2 cutting edges

Usually flank angle is available with 2 cutting edges.

Recommended cutting condition

Comparison video

The machining noise difference is remarkable.Please refer Iscar web site for more detail.

CXMG insert:

https://www.iscar.com/eCatalog/Family.aspx?fnum=4249&mapp=IS&app=0&pageType=4&rel=I

External diameter holder:

https://www.iscar.com/eCatalog/Family.aspx?fnum=4249&mapp=IS&app=0&GFSTYP=M&fr=1

External diameter holder with oil hole:

https://www.iscar.com/eCatalog/Family.aspx?fnum=4245&mapp=IS&app=0&GFSTYP=M&fr=1

Internal diameter holder:

https://www.iscar.com/eCatalog/Family.aspx?fnum=4242&mapp=IS&app=0&GFSTYP=M&fr=1

-

Conventional CCMT insert

Economical as the number of available corners is doubled with the same sharpness.

-

CNMG insert for finishing

The specific flank angle design makes it suitable for finishing.

-

CNMG insert with high cutting force

High rigidity because the back of the cutting edge is a seat surface structure for receiving cutting resistance.

-

CNGP/CNGX insert

Greater sharpness by the high rigidity design and specific flank angle.