Economical collet chuck options

YG-1 toolings

YG-1 has the image of solid endmills and solid drills manufacturer, but Cominix also has ER collet chucks from YG-1.

The price is more affordable than the collet chucks made by other companies in Japan, but how is the performance?

INDEX

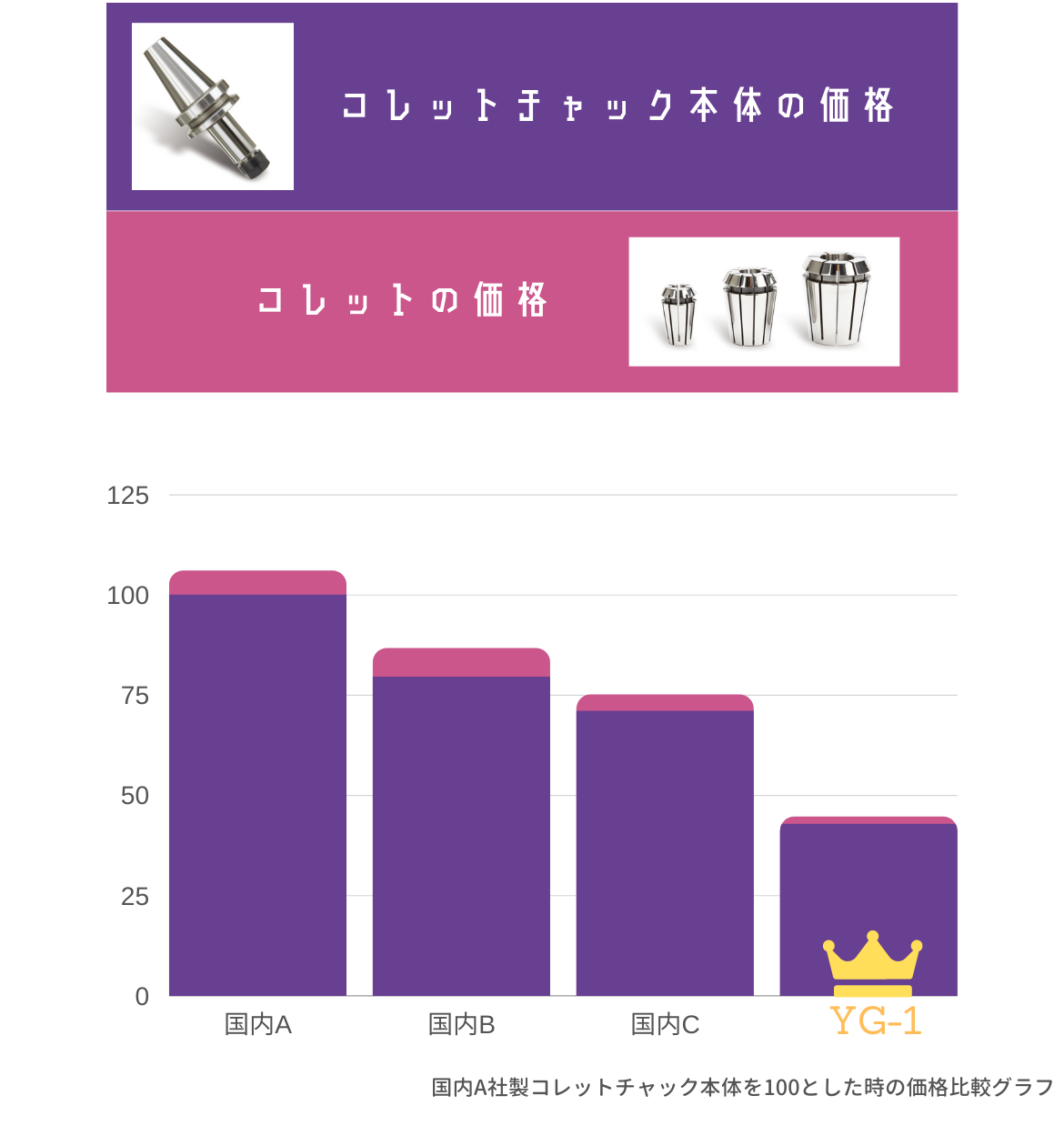

Appealing sales point 1: Cost advantage

*Comparison of similar size to ER20 by double contact BT40

Appealing sales point 2: Wide lineup

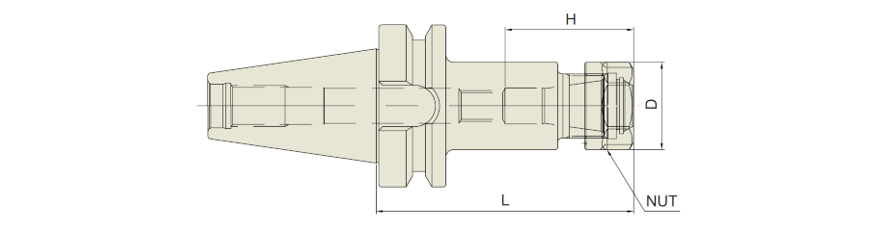

-

Double contact CBT 30, 40, 50, HSK A63, HSK A100 are prompt delivery inventory.

Streight shank types are also prompt delivery inventory.

-

ER collet compatible with other companies.

Size lineup: ER11, (etc)

Available to clamp Φ0.5~30.

CBT50-ER20 has a rich lineup of length: L=90mm, 105mm, 120mm, 135mm, 165mm, 200mm, 250mm, and 300mm

(Reference information)

Length line up of collet chuck made by Japanese manuafcturer A: L=75mm, 90mm, 120mm, 165mm, 200mm, and 250mm

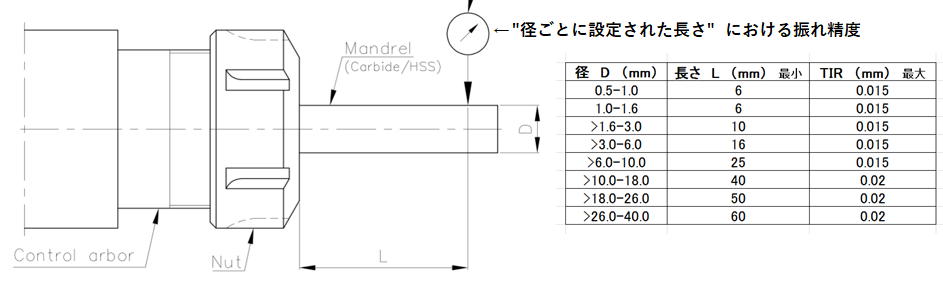

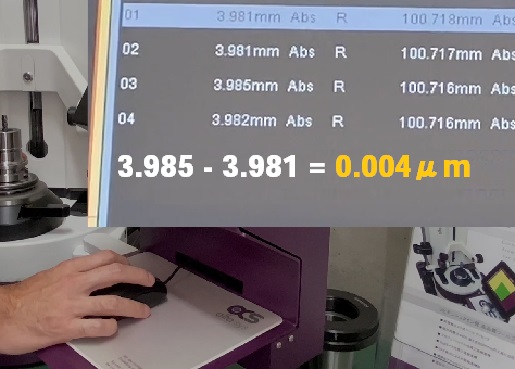

Runout accuracy

It is the runout accuracy at the length for each tool diameter.Please note that Japanese manufacturers often describe it as diameter to μm.

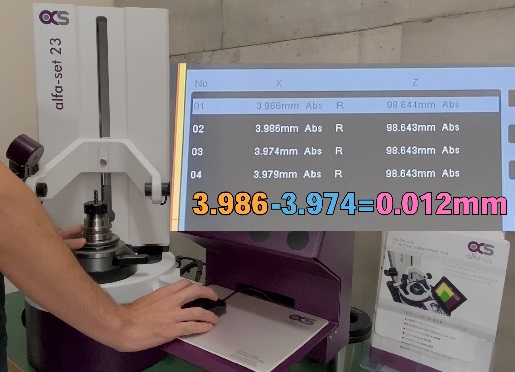

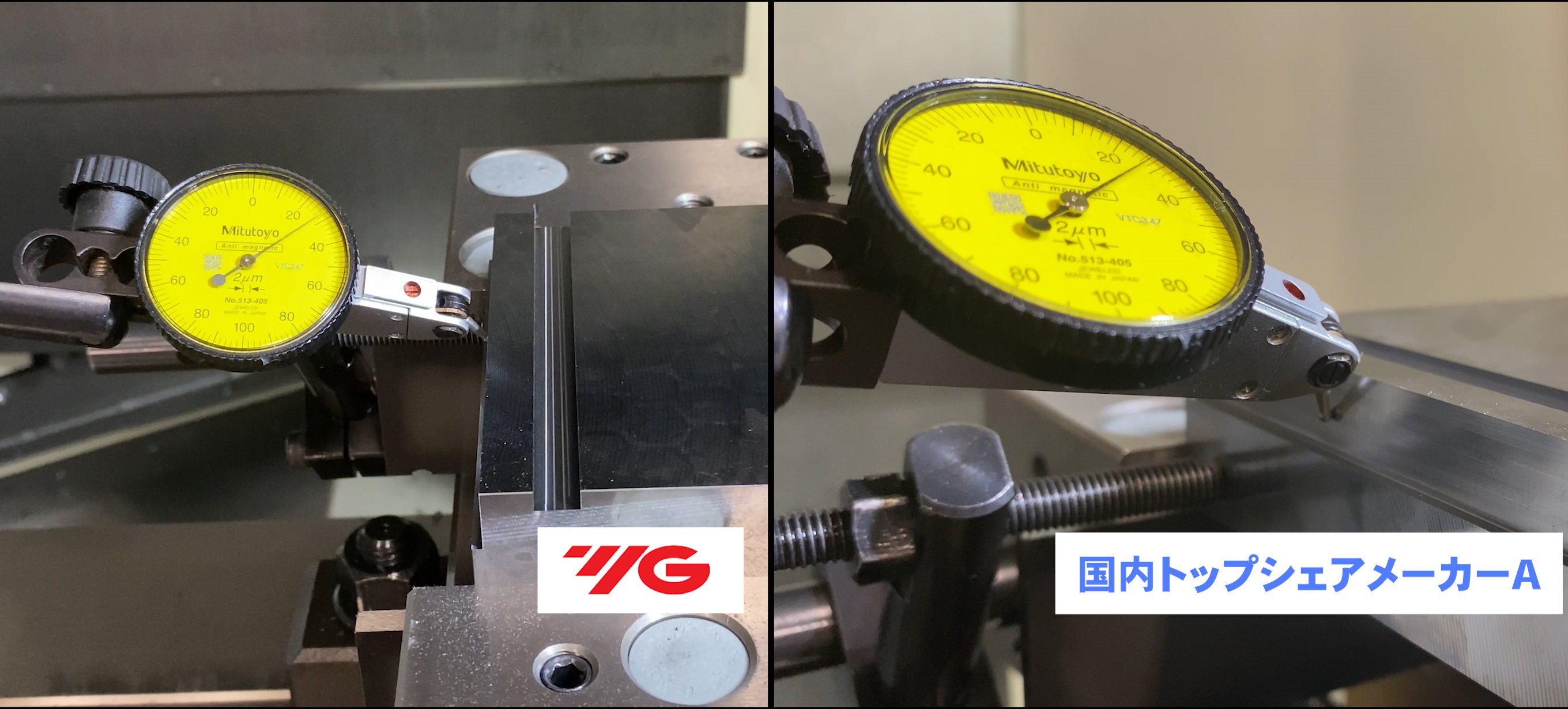

Comparison test report (YG-1 vs. Japanese manufacture A)

Compared with the collet chuck made by Japanese manufacturer A which boasts the top share in Japan with high runout accuracy.

The purpose is to check that it can be used in ordinary processing and whether it can be used as a cost reduction idea.

Result: Under general processing conditions for general steels, it can be used without much difference from high-performance products.

Tesr report is as follows.

-

Machine

Mazak VCN-430A(BT40) -

Workpiece clamping condition

Size: 200mm square x 30mm length

Material: S50C

-

YG-1 collet chuck

(Product code:The runoutis 12μm by general collet

-

Other manufacturer's collet chuck

(The same size as YG-1)The runout is 4μm by high precision collet.

→ In side milling, there was almost no difference due to collet chucks compared to Japanese top share manufacturer.

There was a difference as a value, but there were some parts where there was no difference by the measurement position.

→ YG-1 collet chuck could be used without problems even in 0.5D slotting.

Explanation video

Documentary video of YG-1 collet chuck

We held an audition to find a talented tool.