cominix Tech asks:YG-1 Japan

Wide product lineup with wide price range.

A tool manufacturer that boasts the world's top share in round tools.

More than two years have passed since COMINIX started selling YG-1 products. We interviewed them to find out what kind of tool maker YG-1 is.

While COMINIX handles various cutting tool manufacturers, which target should we suggest YG-1 tools?

Also, we asked for the cooperation of YG-1 Japan as a COMINIX technical center member.

(From left) President of YG-1 Japan Mr. Moon, Mr. Suda, and Mr. Mori

----------Hello everyone. Thank you for making time for us to have this meeting. Now, let us start.

YG-1 products boasting a high market share

----------YG-1 is South Korean cutting tool manufacture as you know, how is the current market condition?Mr. Moon: The cutting tool market in South Korea is about 230 billion yen (Editor's note: about 400 billion yen in Japan), but due to the influence of COVID-19, demand keeps sluggish by production reduction in the main industry which is automobile. South Korean economic growth is expected to be moderate among G20 and 37 OECD countries. YG-1's growth rate was 2% in May, but I suppose it would be declined sharply from June.

----------How is the market share in South Korea?

Mr. Moon: The market share of YG-1 in Korea is 50% for end mills, 70% for drills, and 40% for taps, which is the largest share in South Korea. Production sites are not only in Korea, but also in Germany, in the USA, in Canada, in India, and 2 prodction sites in China.

We mainly sell standard products, but recently the need for special products has become very high, so we have technical centers in Germany and the USA to provide solutions. YG-1 has a high overseas ratio of sales and a wide range of sales destinations. More than 70% of sales are for North America, Mexico, Latin America, Europe and Asia. On the other hand, the overseas ratio of Japanese tool manufacturers are about 30% to 40%, and I suppose main sales destinations are Asian region.

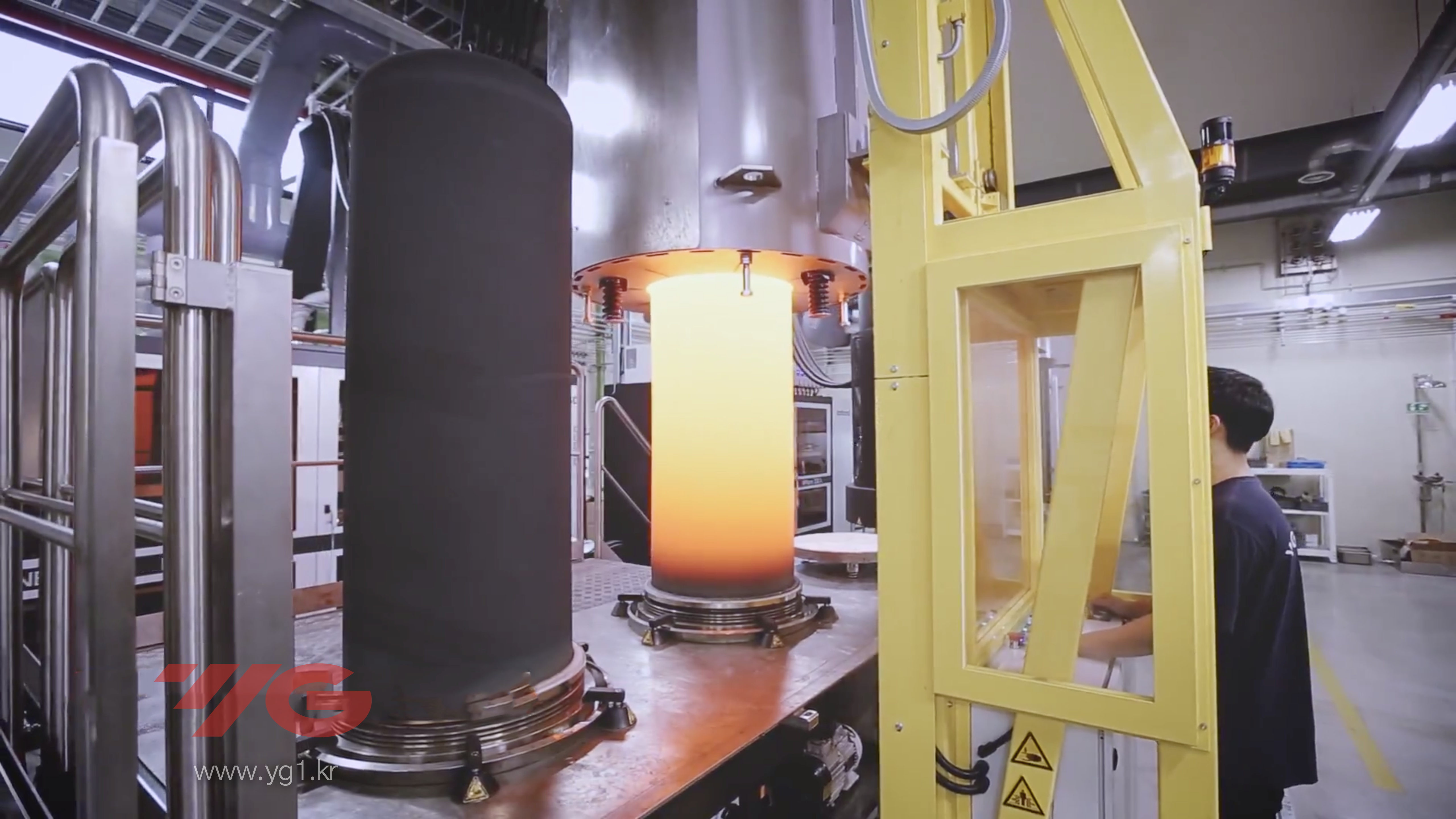

(From YG-1 official Youtube channel)

YG-1 Sales Strategy

----------Who is the main user of YG-1 products?Mr. Moon: Main users are automobile industry, aircrafts, semiconductors, power generation related parts, etc.

----------Are there any competitors who have a high probability of changing to YG-1 products or who have many cases of changing to YG-1 products?

Mr. Moon: Globally, most of the strong field products have been changed to our products, so I suppose we do not have much competitors. Rather, we believe that it is our mission to meet the needs of our customers through YG-1 products. However, we need to develop the Japanese market more.

----------Do you have any unique product from the category of the workpiece and machines?

Mr. Moon: Main strong point is that we have a wide range of products for mold processing. In addition, small-diameter size products are specially designed and manufactured for the Japanese market. We are developing various products, but I think that the carbide solid endmill is the first choice to recommend. Japan is a huge market, and there are many competitors even only carbide solid endmills, but we have a wide product lineup, so we believe that we can meet users' needs.

(Supported by YG-1 Japan)

----------How do you develop products?

Mr. Moon: In the old days, our CEO, Mr Song decided all new product developments. Now YG-1 has changed that the development team plans the product by reflecting the voices of users all over the world collected by the sales staff, and the marketing team research the market to commercialize it. However, Mr. Song developed a lot of items for a really long time. Now, YG-1 product development team has people from around the world who have a wealth of knowledge and experience. There are some who worked in the development position of other tool manufacturers.

----------Is the employment system of South Korean manufacturing industry like Japanese system which employees work at 1 company for a long time or Western system which is opposite to Japanese system? Is YG-1 relatively Western employment system?

Mr. Moon: For a long time, the employment system in South Korea was the same as in Japan, and it was common for people of my generation and above to work for one company for a long time. However, the employment environment in South Korea has changed drastically these days, and it is not uncommon to change jobs for raising positions and salaries.

The highest quality and low price are required to Japanese market

----------Are there any differences between Japanese cutting tool market and overseas cutting tool market?Mr. Moon: I worked at the South Korean headquarters for 18 years, expanded sales of YG-1 products in North America, Latin America, Europe and China, and transfered to Japan two years ago. My impression is that the Japanese market is the most difficult market in the world.

The markets other than Japan are very simple. The needs for high quality and high prices and the needs for low cost and general-purpose use are clearly separated. The needs for technical support are also limited. At first, we were able to raise awareness of YG-1 products and increase sales by selling general-purpose products.

On the other hand, the Japanese market is extremely strict about quality and inventory status, and if everything is not perfect, including human relationships and technical support, a business transaction cannot be completed. Also, even high quality products are generally quite less expensive.

Since there are so many cutting tool manufacturers in Japan, I think it is very difficult to increase sales in Japan even for brands that have a global share in Europe and the USA. We have confident that YG-1 has been successful in several large markets around the world, including Europe, the USA and China, but the Japanese market is the final stage for the success of the YG brand. To acheive the success, I believe that we must provide more support to COMINIX in terms of quality, price, and product lineup.

Unfortunately, the Japanese ecomony is expected to worsen due to the influence of COVID-19, but we believe this is an opportunity to expand our market share. This is because both dealers and users will begin to find and use more competitive products from around the world as economic conditions deteriorate. We, YG-1 Japan want to stand between Cominix and YG-1 headquarters to deepen cooperation, and break through the current situation.

We do not know a clear way to build a stable foundation with current economic conditions, but COMINIX has a wide sales network such as wholesale business and direct sales business not only in Japan, but also in the world. I believe this is one of the way to continue business.

If you are reading this article and have any concerns about the price or supply of the product you are using, please feel free to contact us.

The first project was successful

----------Could you give us your honest opinion about Cominix sales activities?Mr. Moon: I think the first project with COMINIX was successful. The second project has been successful in the Kansai region, but I feel that there is room for further growth in other regions. I understand that it will take a lot of time to grow sales in the Japanese market.

I would like to consider together with Cominix how to propose and how to let users try YG-1 products which have used all over the world.

Mr. Mori: We would like to prepare and provide more technical information of products.

----------I understand. Since we are a trading company that specializes in cutting tools, we cannot just say "this is a tool for XX" to the users, and it is difficult to propose other applications. For example, if it is a "tool for stainless steel", we can guess the welding resistance and sharpness, and deep cutter sweep. If the sharpness is good as expected, we can propose machining with low mechanical rigidity and measures against burrs.

However, for our proposal sales style, the reason is the most important why the tool manufacturer is recommending for stainless steel. This is because it may be less sharp than the current product depending on the shape of the cutting edge. I think this is a general situation not only for us but also for users.

(Supported by YG-1 Japan)

Mr. Mori: As you said, I think that is the reason why overseas tool manufacturers, which have a large global share, are not increasing their share in the Japanese market. They don't disclose too much information. We will try to break through it.

Mr. Suda: We recognize that it is a big problem for us that we do not prepare proper technical information and test reports which are basic support of Japanese manufacturers. Although it will take some time, we will persistently request the head quater to change awareness and work to disclose such information.

How we can deliver YG-1 products

----------COMINIX Technical Center try to make data and disclose information for explaining the characteristics of cutting tools objectively and logically. However, it is difficult to select competing products and set cutting conditions now.Based on my sales experience, I select the compete tool and similar workpiece material for the test, but I would like to refer YG-1's case study in the future. It is difficult for Japanese cutting tool manufacturers to provide this kind of information, but how about your company?

Mr. Moon: We have a system that allows to collect and to refer test reports from all over the world. We will use and share it with you near future.

(From YG-1 official Youtube channel)

----------At the end, do you have any message for readers of this article?

Mr. Moon: We are focusing not only on general-purpose products, but also on high-end products such as V7plus, X5070 and 4G Mills for specific workpiece materials. YG-1 wants to support improvement by proposing various product groups to users and dealers, including Cominix. After that, I believe the key point is how we can deliver the product. Anyway, I want users to try using our products once.

----------Thank you very much for your time today.

Thank you.

(Supported by YG-1 Japan)

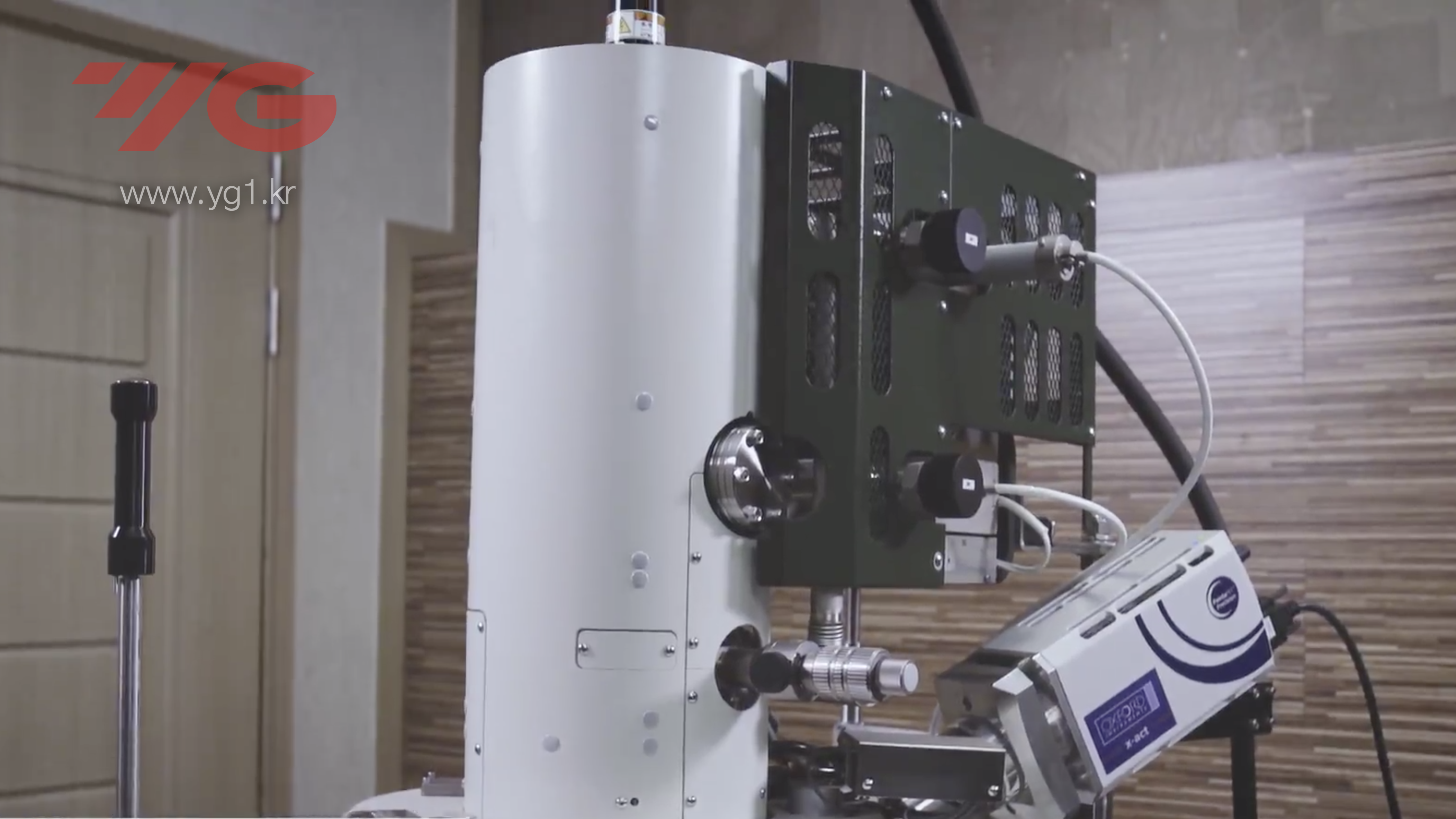

This is for analyzing competitors' products.

(Supported by YG-1 Japan)