Ideas for Interference Avoidance and Automatic Correction of Diameter

Automation and labor saving are possible depending on the idea

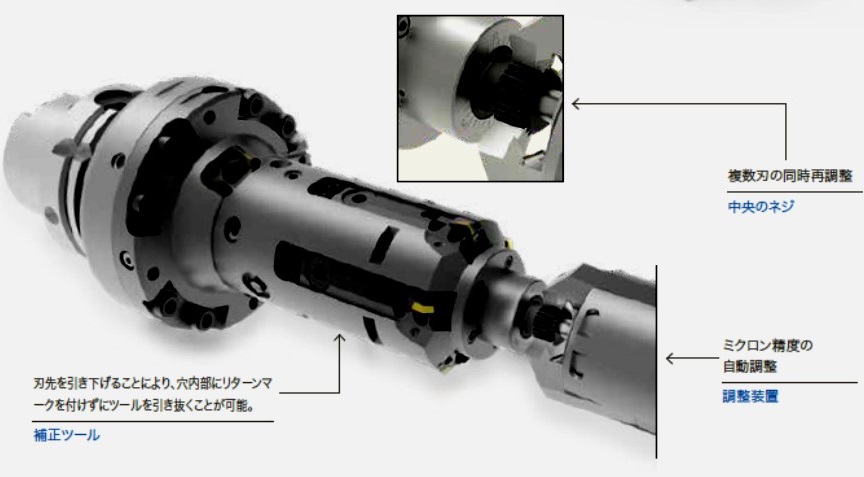

MAPAL's actuated tools have a wide variety of mechanisms and shapes.

In addition, they have a production site dedicated to actuation tools.

We can introduce various processing results.

MAPAL web site

Q. What is an actuation tool?

A. It is a tool with mechanism that can move the cutting edge.

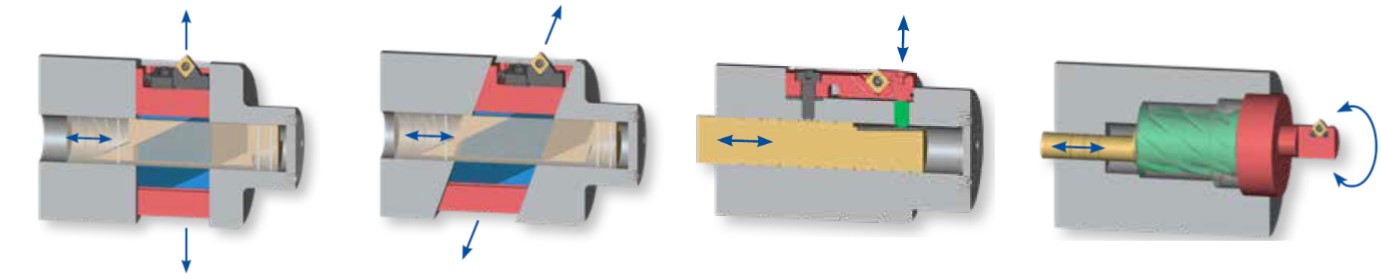

Firstly, explaining actuation tool mechanism and tools.

Example 1: Input by coolant pressure

-

Mechanism on the machine connection side

You can reach the machined part while storing the cutting edge by stopping the coolant to avoid interference.

-

Mechanism on the cutting edge side

When you reach the part you want to process, turn on the coolant. The coolant that mediates the oil activates the mechanism to move the cutting edge at any time.

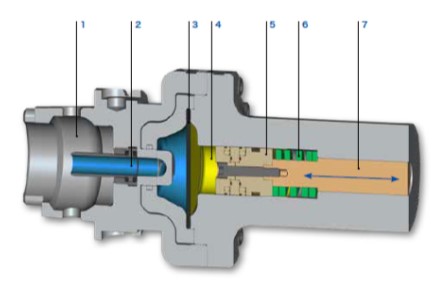

Actual tool and machining part illustration

Even on the machining center, you can process taper processing that the cutting edge slides and widens the back side by controlling the coolant pressure to move the cutting edge

Example 2: Automation of night operation (Automatic correction of diameter)

An actuation tool that operates by changing the coolant pressure or touching a jig or workpiece.

Example: cylinder bore in engine blocks (An actuation tool with 2 functions)

1) By changing the coolant pressure, the cutting edge moves in and out, and the tool can be pulled out without damaging the hole after machining.

2) Cutting edge wear compensation takes place, after feedback from a measuring station, automatically atan adjusting device via the central screw on the dace side.

This allows to continue processing at night without adjusting the diameter by people.

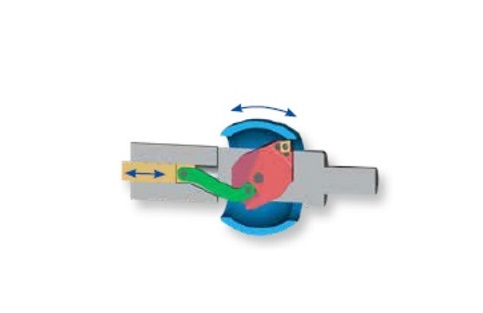

Example 3: High precision setting

Input by drawbar or push rod

-

Internal mechanism of drawbar/push rod

The drawbar/push rod mechanism is one of the most rigid actuation tools, so high-precision machining is possible.

-

Mechanism on the cutting edge side

The drawbar / bush rod mechanism is one of the process that requires a large range of motion.

Machining equipment compatible with this mechanism is required.

(The pink part is the moving part)

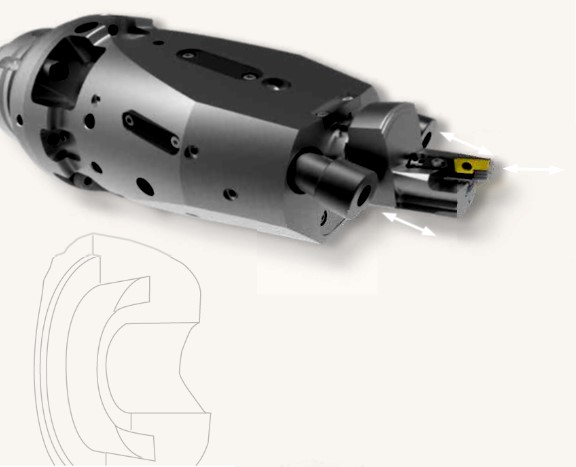

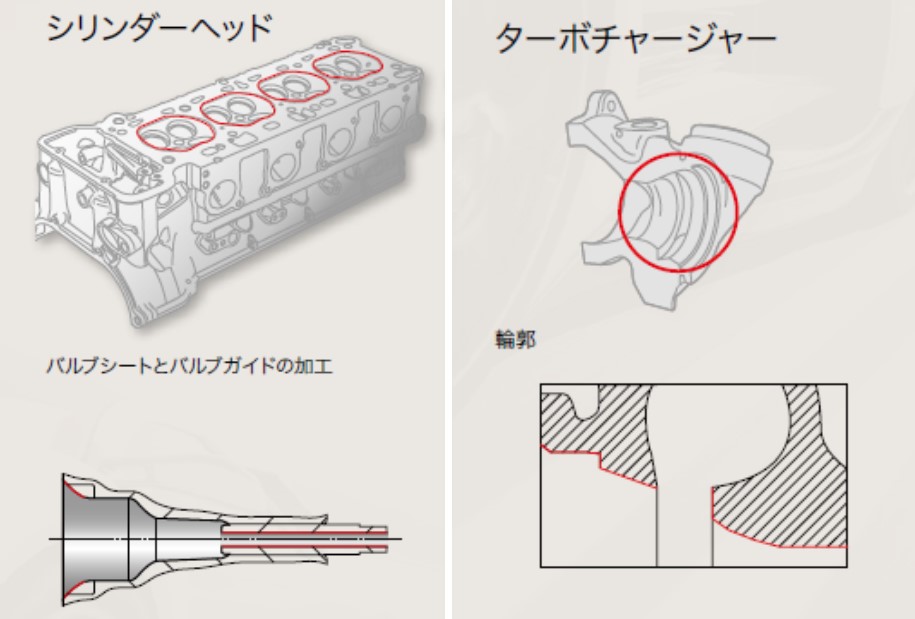

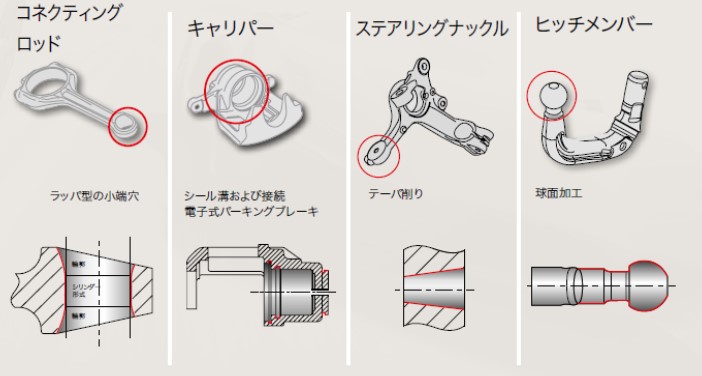

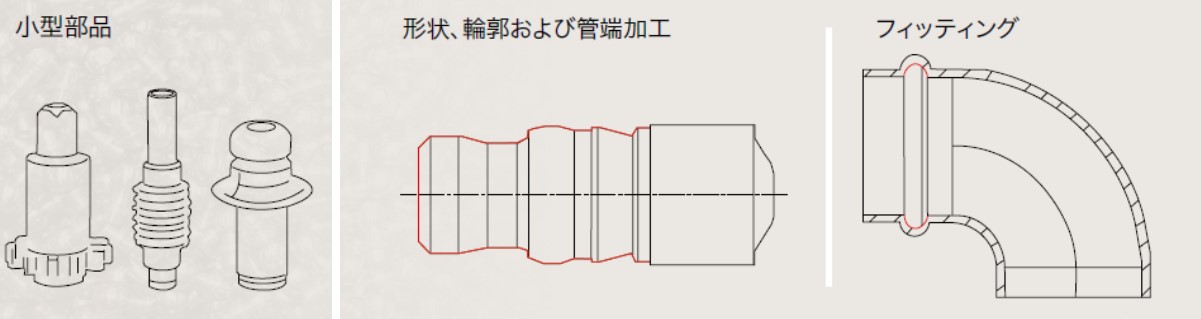

Processing that utilizes actuation tools

Since contouring can be processed on the machining center instead of turning, small lots can be processed with existing equipment, or the number of units can be reduced when purchasing new equipment.

(By using Tooltronic, a U-axis system made by MAPAL)

Others

We offer various actuating mechanisms.We will suggest the most suitable actuation tool depending on the condition of the jig and the condition of the machined part such as blind hole / loophole.

For other cases and processing ideas, please see the MAPAL Actuating Catalog.