High-Precision Hole making to correct any Misalignment

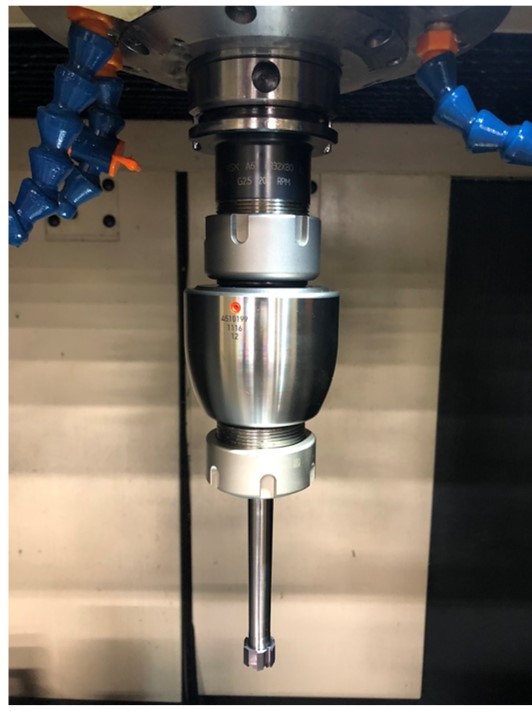

GFIS: Floating holder

GFIS holder has floating mechanism.Possible to attach to ER32 collet chuck.

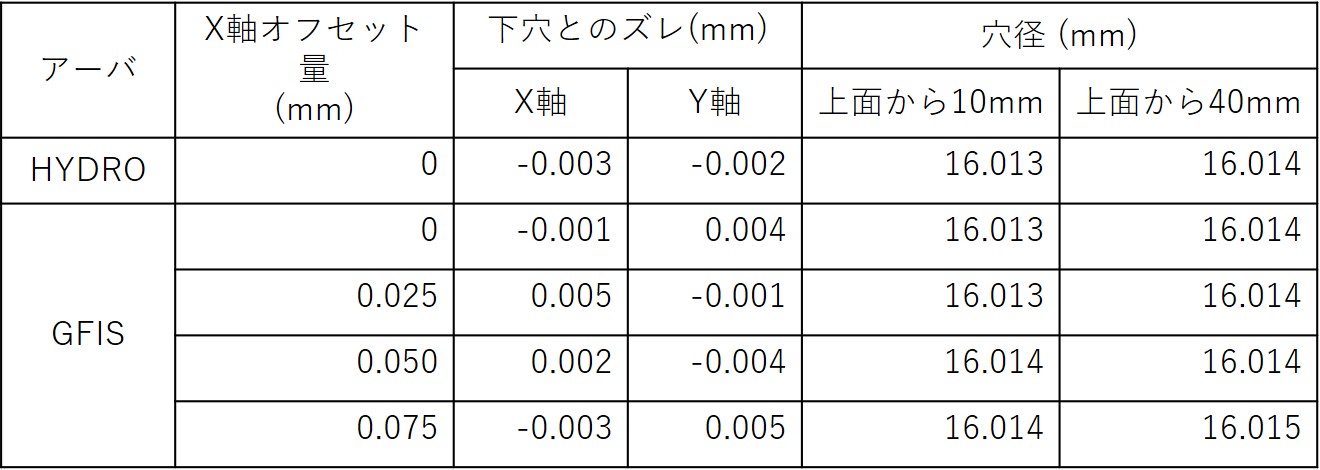

Test machining

Reaming: RM-BN6-16.000-H7SA IC908 (indexable reamer)

-

Workpiece clamping condition

-

Machine: Mitsui Seiki Kogyo

Vertex 550-5X(HSK-A63)

Coolant:Solution 10%

Tools for comparison

-

GFIS ER32X70-ER32

Collet chuck holder with floating system

(Testing with ER32 collet chuck and GFIS holder)

HSK-A63 HYDRO 16X95

Iscar HYDRO Chuck

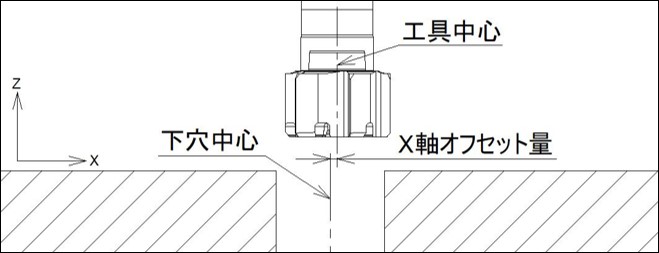

We got the same result: GFIS holder with misaligned 0.075mm from the center and HYDRO chuck without offset.

Expected machining is possible by floating holder even the machine is misaligned.

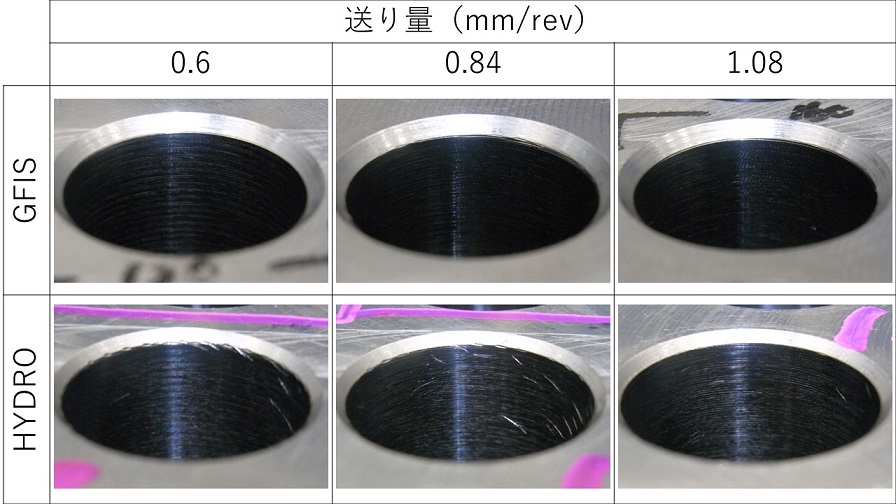

Hole surface after reamer processing

GFIS holder has quite smooth surface.

Appealing sales points, object candidates of changing, and attention

-

Attach to collet chuck

You can use your own collet chuck.

-

Improve hole accuracy

In case not finished with intended hole diameter.

-

Improve surface damege

In case of poor surface after reaming.

-

Machining with internal coolant

Internal coolant is necessary.