Improve Sharpness and Chip Evacuation Indexable High Feed Endmill

LOGIQ4FEED

FFX4 XNMU

Available from Φ12 tool diameter.

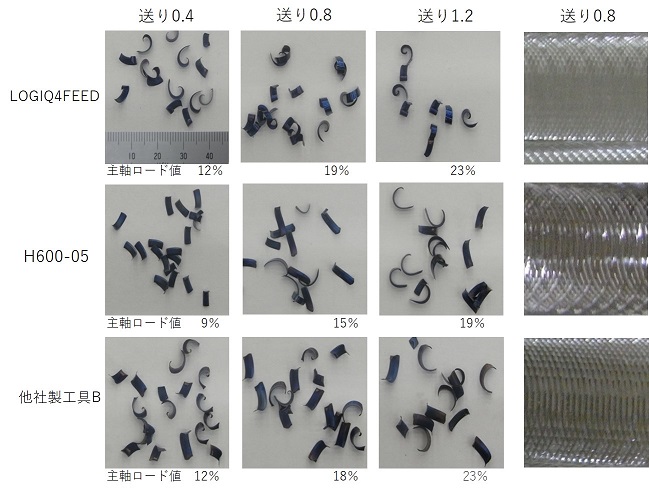

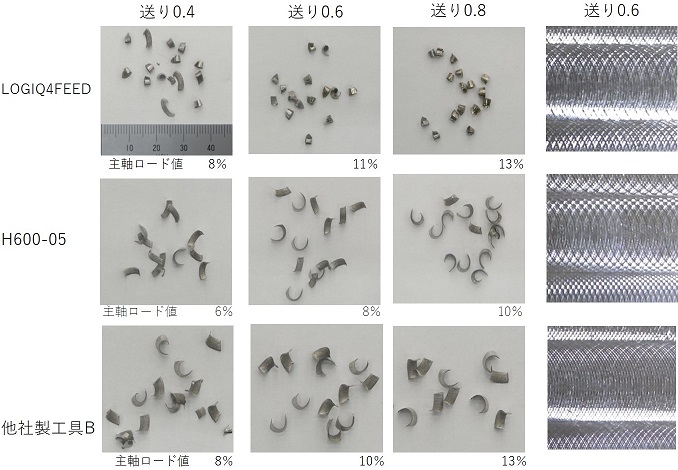

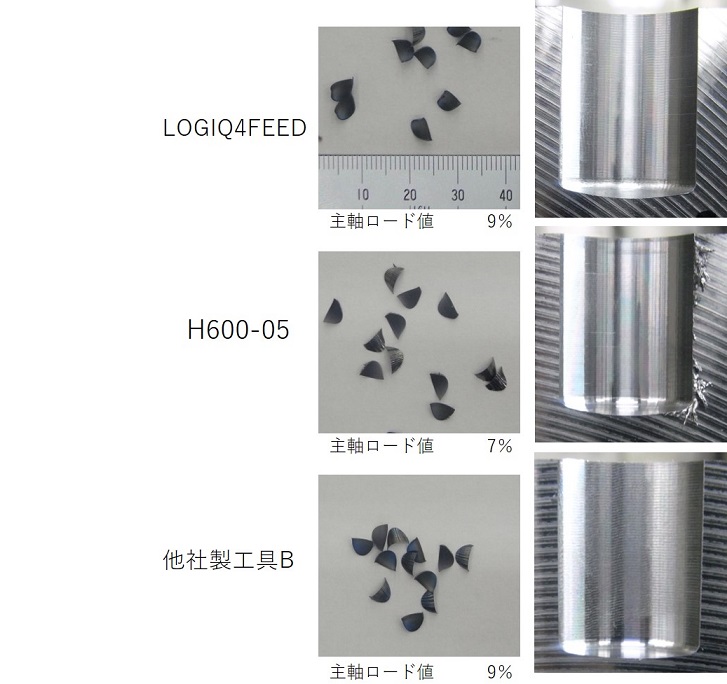

▪Here are comparison test results of Iscar's tool and other manufacturer's tool. High feed machining can be processed even in small machine tools due to the large rake angle of the insert.

-

Double-sided insert with enough web thickness

The web thickness that determines the rigidity of the endmill is firmly secured even with a double-sided insert.

-

Large rake angle

Rake angle is enlarged for the purpose of increasing sharpness.

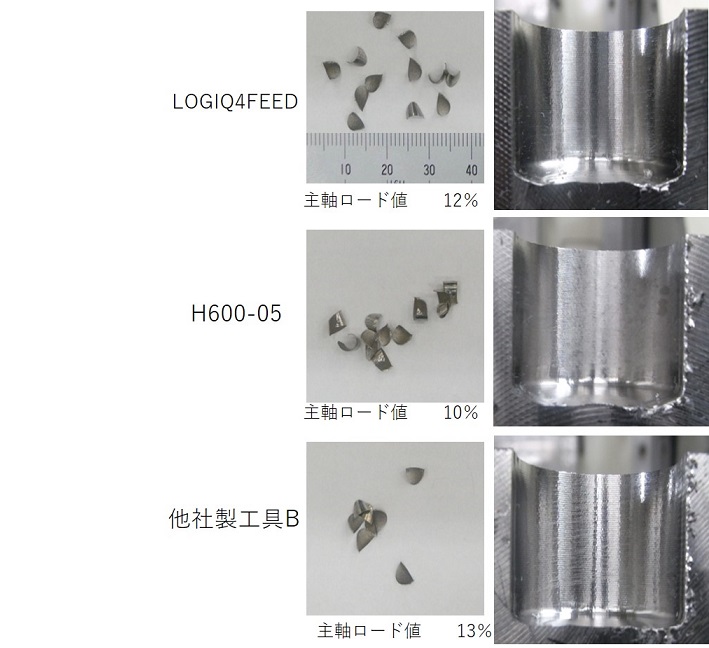

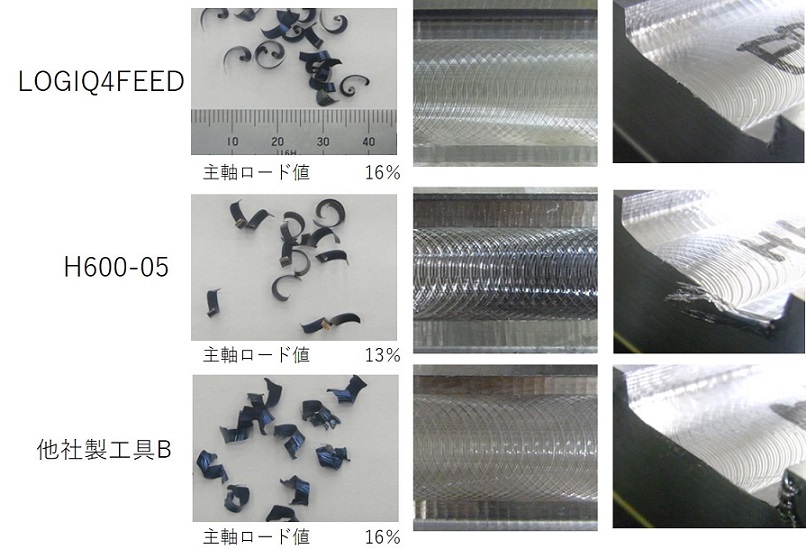

Comparison test

LOGIQ4FEED / Iscar H600 vs. Other manufacturer's high feed tool

-

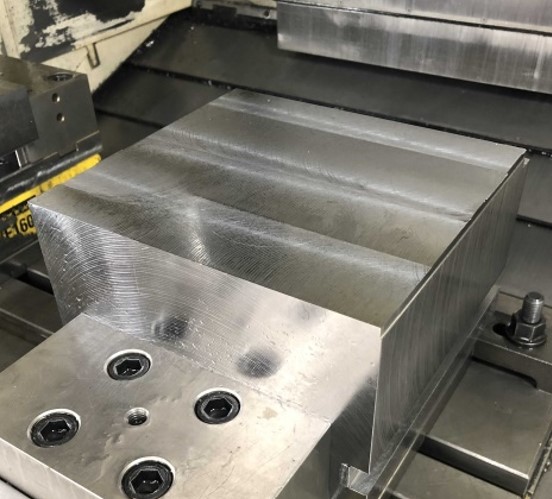

Machine

Okuma CorporationMA550VB

BT50 vertical machining center -

Workpiece clamping condition

Workpiece size: 200mm square x 120mm height, block

Workpiece material: SCM440、SUS304

Testing Tools

-

LOGIQ4FEED

Cutting edge angle: 17° Shank size: Φ12,16,20,25,32 Max. depth of cut: 0.8mm No. of corner: 4corners No. of edge: 4edges -

Iscar H600-05

Cutting edge angle: 17° Shank size: Φ25,32,40 Max. depth of cut: 1.0mm No. of corner: 6corners No. of edge: 3edges -

Other manufacturer's high feed tool

Cutting edge angle: 12° Shank size: Φ16,20,25,32 Max. depth of cut: 1.0mm No. of corner: 4corners No. of edge: 4edges

Test result:

Better surface with LOGIQ4FEED.

Reduce galling on plunging and surface burrs on slotting.

Face milling:SCM440

Vc=150m/min、ap=0.5mm、ae=15mm

* There is no significant difference in the surface due to the difference in feed of the same tool.

Face milling:SUS304

Vc=100m/min、ap=0.5mm、ae=15mm

* There is no significant difference in the surface due to the difference in feed of the same tool.

Plunging:SCM440

Vc=120m/min、fz=0.07mm/tooth ap=20mm、ae=3mm

Plunging:SUS304

Vc=80m/min、fz=0.07mm/tooth ap=20mm、ae=3mm

Slotting:SCM440

Vc=120m/min、fz=0.4mm/tooth ap=0.5mm、ae=25mm

Recommended cutting condition

Please refer Iscar web site for more detail.

Insert:

https://www.iscar.com/eCatalog/Family.aspx?fnum=4291&mapp=ML&app=0&GFSTYP=M&fr=1

Holder:

https://www.iscar.com/eCatalog/Family.aspx?fnum=4291&mapp=ML&app=0&pageType=4&rel=T

-

Small Diameter indexable high feed insert

Indexable tools often have problems like lack of sharpness and chip evacuation. This product's design will solve such problems.

-

For various workpiece material

You can use for various insert grades by using just one holder.

-

For various application

Wide lineup of holder with face miliing type, multi master type, etc.