Wedge Clamp with Internal Coolant System

Internal coolant system

Strong and reliable clamping mechanism prolongs tool life.

Coolant jet directed to the cutting edge.

External diameter holder lineup: 20mm square and 25mm square (C, D, and W insert can be attached.)

Internal diameter holder: Minimum cutting diameter Φ40 (The standard product is a type with a CN12 insert attached.

Concept video

Coolant efficiency difference by insert temperature

Coolant efficiency drops by coolant evaporation when the insert temperatur is high.

It is possible to increase the efficiency of coolant supply by keeping the cutting edge cool properly

Minimum cutting diameter is Φ40 for internal diameter

Only Iscar has a standard lineup of hollow clamp that serves also as coolant nozzle with a minimum cutting diameter of Φ40.(According to our research in 2019)

Pdoduct code and sizes(Iscar web site)

https://www.iscar.com/eCatalog/Item.aspx?cat=3340676&fnum=4263&mapp=IS&GFSTYP=M&srch=1

Machining test with middle pressure machine

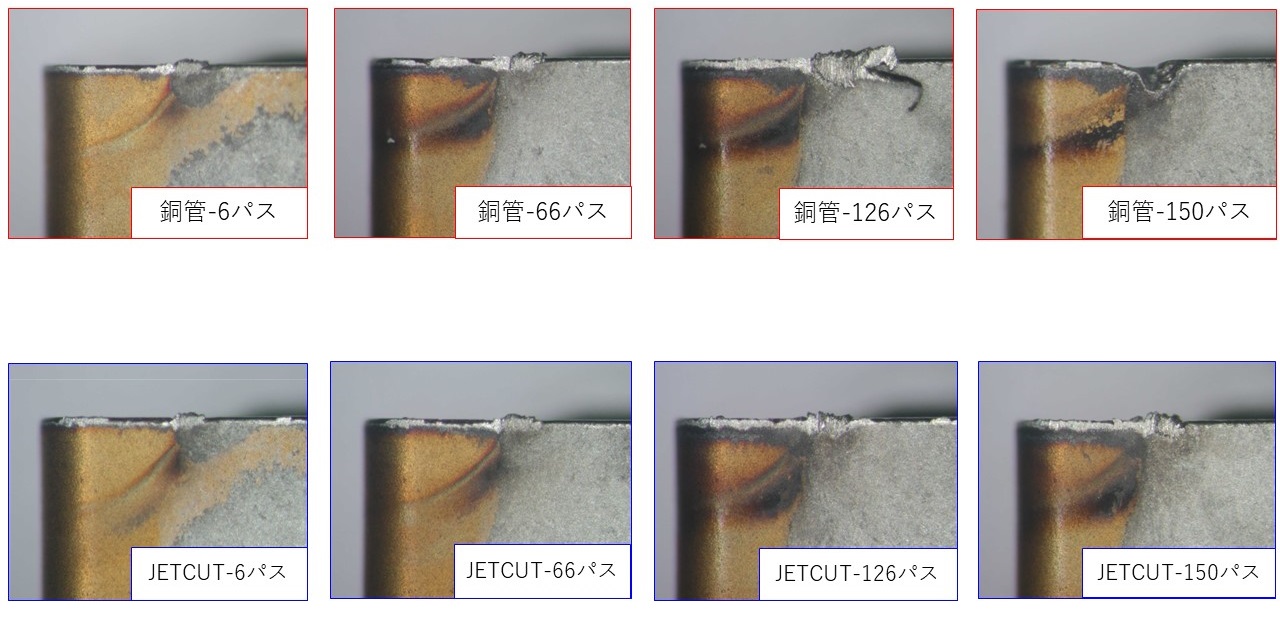

Coolant supply from copper pipe vs. Coolant supply from JETCUT

Machine:DMG MORI NL2000/700MC

Workpiece material:SUS304

Cutting speeed:Vc=150m/min

Feed:f=0.2mm/rev

Depth of cut:ap=1.0mm

Coolant:Emulsion with 8%

-

Coolant supply from copper pipe

Both looks to be able to properly jet to the cutting edge.

How different the coolant supply efficiency by different coolant system? -

Coolant supply from JETCUT

Test result

With the copper pipe supply, boundary wear and welding became remarkable from 126-pass and occurred chipping of the cutting edge.

On the other hand, with JETCUT supply, the progress of wear and welding is suppressed even after 126-pass.

In addition, JETCUT get slightly welded at the end of 150-pass, but it is about the same condition as 66-pass with the copper pipe supply. It can be judged that continuous machinign is possible.

As a test result, JETCUT can further extend tool life than copper pipe supply even the coolant is supplied accurately from copper pipe.

Please refer Iscar web site for more detail.

C type external diameter holder:https://www.iscar.com/eCatalog/Family.aspx?fnum=4261&mapp=IS&app=0

D type external diameter holder:https://www.iscar.com/eCatalog/Family.aspx?fnum=4259&mapp=IS&app=0

W type external diameter holder:https://www.iscar.com/eCatalog/Family.aspx?fnum=4262&mapp=IS&app=0

C type internal diameter holder:

https://www.iscar.com/eCatalog/Item.aspx?cat=3340676&fnum=4263&mapp=IS&GFSTYP=M&srch=1

-

Machining on stainless teel and titanium

Good choice for machining where welding is occurred on the cutting edge.

-

Finishing machining of steel

Good choice for finishing machining of steel since the cuttig edge is quickly welded by the steel workpiece.

-

High efficiency internal coolant

By supplying from the wedge clamp, you will be able to get better clamp rigidity and high efficient coolant supply.

-

Free from readjustment of the nozzle

Readjustment of nozzle is not necessary at tool replacement and insert changing.