Reduce Semi-finishing of Face Milling

Q. How come semi-finishing process can be reduced?

A.

Since all blades are off by 0.05 mm in the axial direction, there is no need for pre-processing that leaves a small cut by using semi-finishing.

The final edge will be finished the process with itself.

Performance test and surface condition

-

Machine

Okuma Corporation MA550VB

BT50 vertical machining center -

ToolCutter:HTF D100-08-32-R-LN10

Insert:HTP LNHT 1006 ER IC808

Tooling:BT50 SEM 32X48

Cutting condition:Vc=250m/min, ap=0.4mm, ae=70mm

Testing video

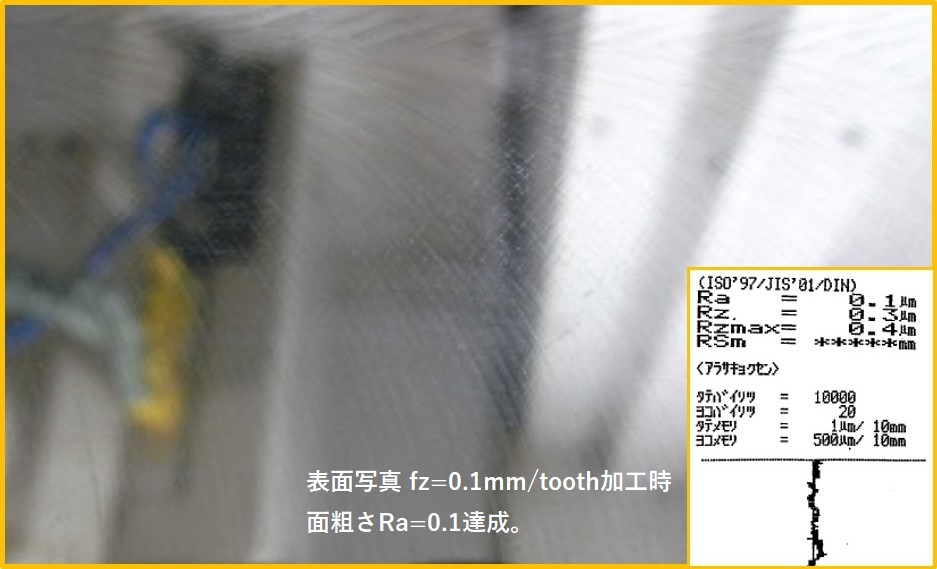

Processed surface

-

Processed surface(fz=0.2mm/tooth)

-

Processed surface(fz=0.3mm/tooth)

Please refer Iscar web site for more detail.

Holder:

https://www.iscar.com/eCatalog/Family.aspx?fnum=4192&mapp=ML&app=0&GFSTYP=M&fr=1&rcat=5606360&item2=&ssOrder=&loc=&IC=

Insert:

https://www.iscar.com/eCatalog/Family.aspx?fnum=2706&mapp=ML&app=0&GFSTYP=M&fr=1

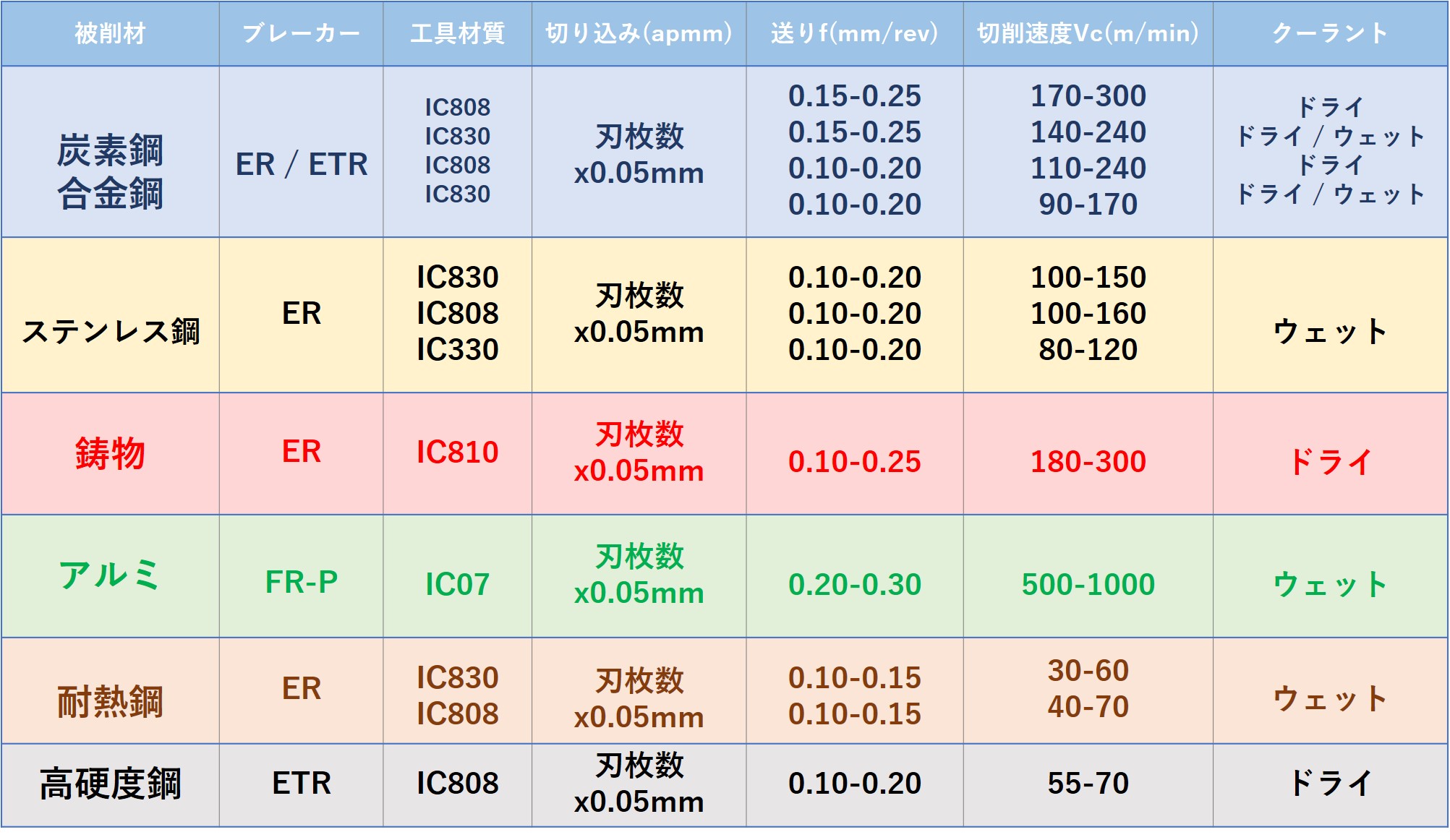

Appealing sales points

-

Reduce semi-finishing process

Reduce tool types, tool costs, and machining time by process consolidation.

-

Available with various workpiece material

Available with a wide range of workpiece materials by combining chip breakers and grades.