cominix Tech asks:A.L.M.T. Corp.

A.L.M.T. Corp.

Grinding and cutting tools made from diamond/CBN materials for various industry.

Manufactures and sells diamond and CBN tools used in a wide range of fields such as automotive, tools, electronics, and semiconductors.

Manufactures tools for various purposes: PCD / CBN brazing cutting tool, rotary dresser for grindstone molding, cutting carbide tools for drills and end mills, wheel for tool grinding, grinding wheel for on-vehicle motor magnet, wafer grinding wheels for semiconductors, etc..

This time, we interviewed them to expect getting ideas for developing a new market.

(From left) Mr. Fukaya, Mr. Nakanishi, Mr. Okanishi

and Mr. Onoda (without photo)

------ Hello everyone. Thank you for making time for us to have this meeting. Now, let us start.

Advantages of A.L.M.T Corp. core technologies

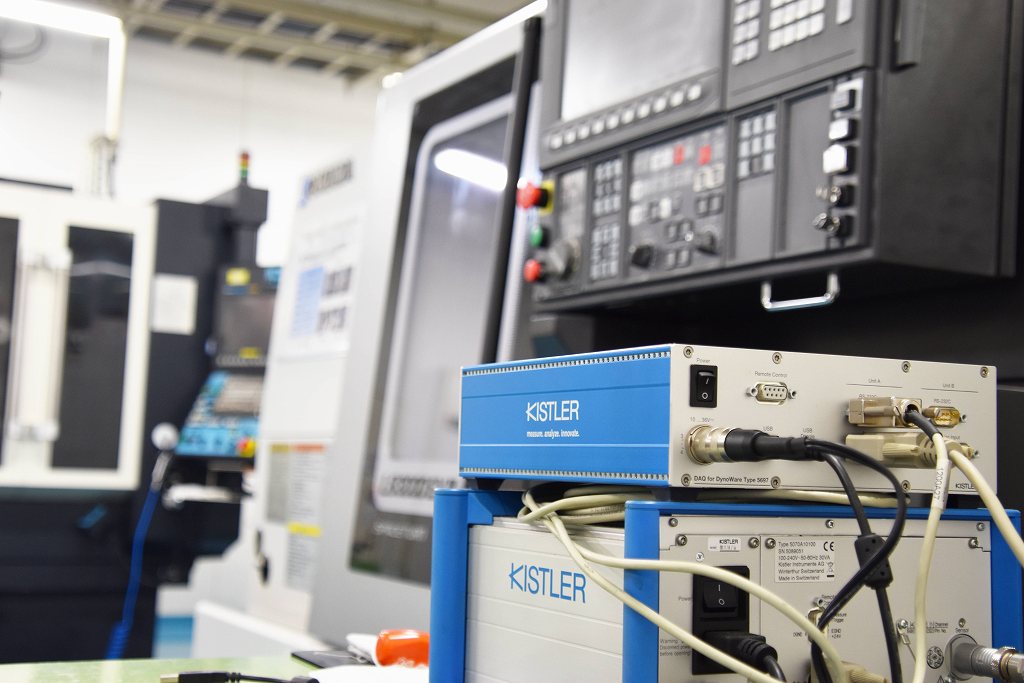

----------Speaking of A.L.M.T. Corp, I have the impression that the facilities for evaluation are very substantial.Mr. Onoda We are focusing on enhancing the customer solution center which is the department that responsible for evaluation which customer can attend the evacuation for tools and cutting process. I think that we are the only company that has an extensive equipment lineup and an organization specializing in evaluation.

Even at exhibitions, we receive comments from everyone, such as "No company is focusing on evaluation same as your company" or "I'm jealous your evaluation environment." We also want to utilize this department as a tool for selling to show off our technologies.

In addition, specialized staff are in the evaluation department to do various evaluations. I think that is a strong point which other companies do not have. Cominix also has specialized staff at the technical center, and I think that is the part that interests users.

(Photo by A.L.M.T Corp.)

----- How many evaluations do you do in a month?

Mr. Fukaya It is about 10 cases per month. There are about 10 evaluations per month, of which 5 to 6 evaluations are done together with customer. There are a few more depending on the month.

----- If it is 20 working days per month, evaluations will be done once every 2 days. You're doing a lot of evaluations.

Mr. Okanish We also do measurement and analysis after processing, then submit a report. So it is really hard if the evaluations of several companies are in a week.

Evaluation is not simply operating the equipment, but also needed to feel the customer needs, so the required skills are high. Sometimes we also need a role as a sales engineer.

Mr. Nakanishi The workpiece and machining that the customers have been in charge for a long time, they have more specialized knowledge than us. So we also study while evaluate.

----- I think that if you do such many evaluations, various ideas will be born that users are unexpected.

Mr. Onoda At the Customer Solution Center, we process various workpieces with cutting and grinding. I think we can propose methods that experienced users could not come up with.

Mr. Fukaya Especially in the field of analysis, we have made such proposals. It is a proposal of analysis and evaluation that can quantitatively capture and evaluate the phenomenon customer want to see.

Mr. Okanishi For example, for composite materials, we can propose improvements by analyzing the difference in plastic deformation depending on the material.

----- So, you are suggesting to change the depth of cut or the rake angle of the tool based on the analysis results.

(Photo by A.L.M.T Corp.)

Even jigs can be proposed by A.L.M.T. Corp.

Mr. Onoda Sometimes we are asked to evaluate a workpiece with a very complicated shape. When I went to see the equipment, I wondered how our technical staff set the workpiece. I am not in charge of the evaluation, so I was really surprised.Mr. Nakanishi That's true. We are making jigs so many times. There was a case that did not work even it was processed by the clamping method specified by the customer. Then I suggested the setting with the jig that I designed. That case was successful.

----------When I had a new workpiece project that I had no idea for clamping and cutting tool, I consulted with your company and got idea to solve.

Mr. Onoda I think it is a strong point that is able to suggest not only the actual machining but also the pre-process.

Mr. FUkaya As Japanese users try to add high value to compete with overseas competitors, we often receive consultations on workpieces with complicated shapes and unprecedented processing methods.

If we process it at our company, we can analyze various things together. I think that it creates a virtuous cycle that leads to the next business.

----------How long does it take from the time you get consultation of the project to the actual evaluation of jig preparation is needed? Do you ever provide the jigs made by ALMT to customers?

Mr. Nakanishi In the past, we had done in two weeks, but it was really a super urgent case. In case we need to make a jig, we ask 1 month lead time if possible. Unfortunately, we do not provide manufactured jigs.

----------Just 1 month lead time even making jigs. That is really fast. Cominix also sells jigs, but as the technical center, we have hardly been able to consider and make the jigs only for the evaluation now.

Mr. Onoda Perhaps because of such system, the repeat rate of customer is very high which is about 80%.

----------Do you charge evaluation fee?

Mr. Okanishi Mostly we do not charge it if we can sell our product. However, recently, we sometimes receive basic evaluation requests for a fee. At the Customer Solution Center, we can faithfully do what customer think.

----------When I hear your stories, it seems that you can almost meet the user's request. Do you have specific thing that you require?

Mr. Nakanishi Yes, I do want to get new equipment... (Looking at Mr. Fukaya)

(Everyone laughed.)

Mr. Nakanishi As customers request sometimes, I want to have centerless equipment. Currently, we are doing simulation tests with alternative equipment, but there are still concerns about reproducibility.

Mr. Fukaya I will seriously consider it. I would like to keep updating and enhancing the equipment.

Enhancing the dissemination of information

Mr. Onoda May I ask if you have any request to our products? We emphasize high rigidity and precision as our appealing points. I often hear requests for delivery dates.

----------Let me see... I do not have specific request to your products, but if you can share more ideas such as success stories, I think that will be useful for our improvement projects.

Mr. Fukaya That is the part that we also consider as an issue. It is a common understanding within the company that it is necessary to increase the number of technical documents and news. This year, I would like to increase.

Mr. Onoda Since our product is in a niche market, I think it is really important to have such a technical idea and to be ready to offer it.

----------Addition to it, I think that coolant is always necessary with grinding. We have some knowledge about the features and specific product numbers of coolants as we suggest them to customer. I think that we can suggest better improvements if we can show the theory and basic condition such as applying coolant method, and nozzle shape.。

Mr. Okanishi I totaly agree with you.

Mr. Onoda We have experienced various evaluations, so I would like to be able to explain coolant apply systematically. Of course, the coolant flow rate is also a very important factor.

Enhancing the relationship with distributors

Mr. Onoda As a new initiative of our company, we will start keep in stock and selling the best-selling products of tool grinding wheels from April 1, 2020. The purpose is to significantly improve the delivery time.

Catalog of A. L. M. T. Corp.

Mr. Okanishi Regarding wheels for tool grinding, our competitors have a lot of direct transactions with users, but we have high percentage to get our distributors support. We will give priority to the distributors who can provide us the information.

----------We believe your product will be our weapon to expand sales to various industries. How do you think relationship with distributors?

Mr. Onoda I think it is important to appeal for distributoers and let them like and get to know our products.

As the customer solution center, we are very welcome to have consultations from users and distributors about anything.

It may not be easy to get the result or may take several years for the results. Even in such cases, we repeatedly proceed to evaluate with our customers. We hope that these efforts will make a fan of CSC and our company.

We are very welcome your consultations.

----------In the end, we were invited to the newly completed cafeteria.

Mr. Onoda This is Blanc Foret, which was completed in October 2018. We had a difficulty to provide lunch to customers who came to visit the evaluation, but now it is good reputation by our customers. The menu changes daily. When they provide special menu which is held once or twice a month, there is a long line of employees to get it.

----------We had a Chinese set meal, and it was voluminous and delicious.

All Thank you very much for your time today.

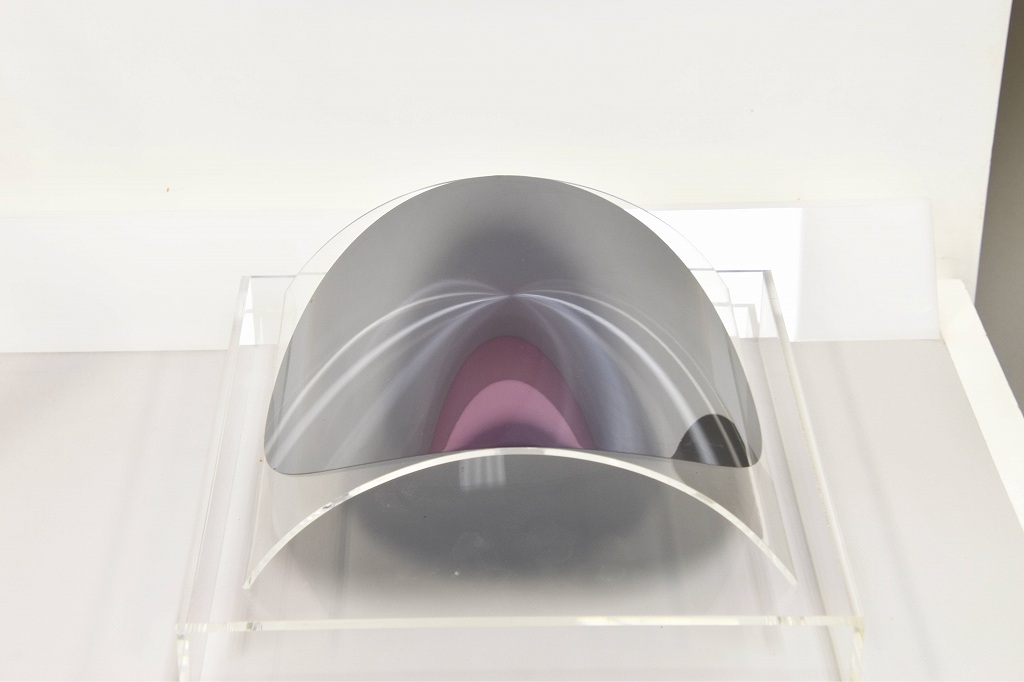

It is required to process it as thin as it can bend.

(Photo by A.L.M.T Corp.)

(Photo by A.L.M.T Corp.)