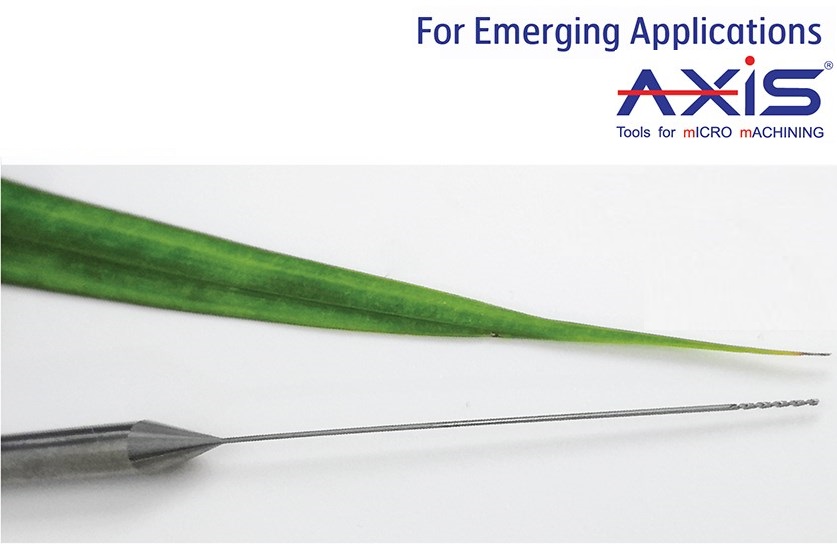

Improve tool performance by MMP technology: AXIS micro drills

Axis micro carbide drill

The COM-SUS and COM-D series of micro drills can improve tool performance significantly by MMP coating (ultra-precision surface finishing) to smooth the surface of cutting edges and grooves.

(MMP coating is available over Φ0.5.)

Index

1.What is "MMP coating" applied to COM-SUS and COM-D series?

MMP stands for Micro Machining ProcessThis can improve tool performance more than precision polished tools by surface treatment which is applied to smooth the cutting edge and groove of the cutting tool like a mirror surface.

-

Reduce cutting force

Extend the tool life is available by reducing cutting force.

-

Improve surface roughness

Improve precision of hole and stabilize machining.

-

Improve chip evacuation

Prevents sudden or chronic tool breakage.

-

Improve sharpness

Reduces welding of the cutting edge, stabilizes the hole diameter, and reduces burrs.

MMP coating allows to meet such needs.

2.Differences of the tool appearance

-

Without MMP coating

-

With MMP coating

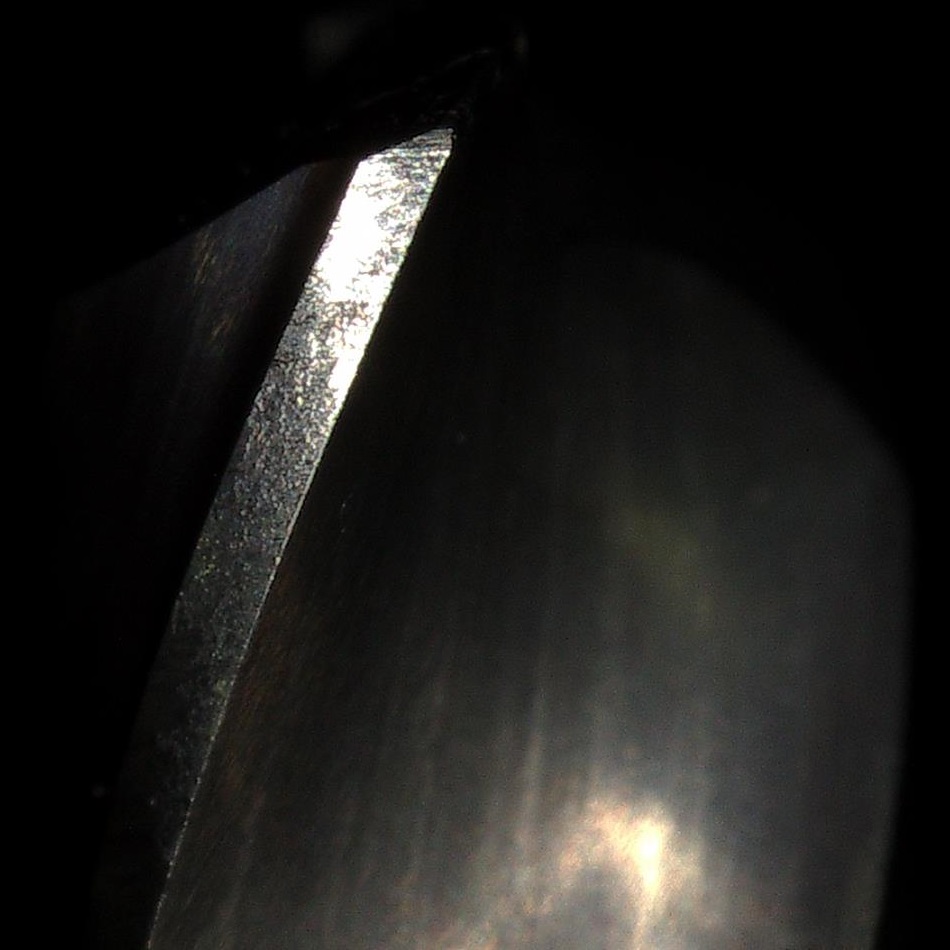

Comparison for edge smoothless (x500)

-

Edge without MMP coating

-

Edge with MMP coating

MMP coating is the technology that can make the surface smooth and improve sharpness with remaining original edge like horning.

3.Test data and explanation video

Workpiece material: SUS304Tool: COM-SUS-0300 (MMP coated Φ3 drill, standard inventory product of Cominix)

Holder: BBT40 PG25x080H (REGO-FIX pressure clamping system)

Collet: PG25-CF 3.0

Machine: VCN-430A (MAZAK BBT 40 vertical machining center)

Cutting condition: Vc=25m/min S=2700rpm f=0.04mm/rev, 4mm depth of cut (peck feed at 1mm)

Performance comparing video: Japanese micro drill manufacturer A vs. AXIS

This is an explanation video of this article

-

Japanese micro drill manufacturer A: Defect in 8m machinnig

-

AXIS COM-SUS drill: Possible to keep using after 40m machining.

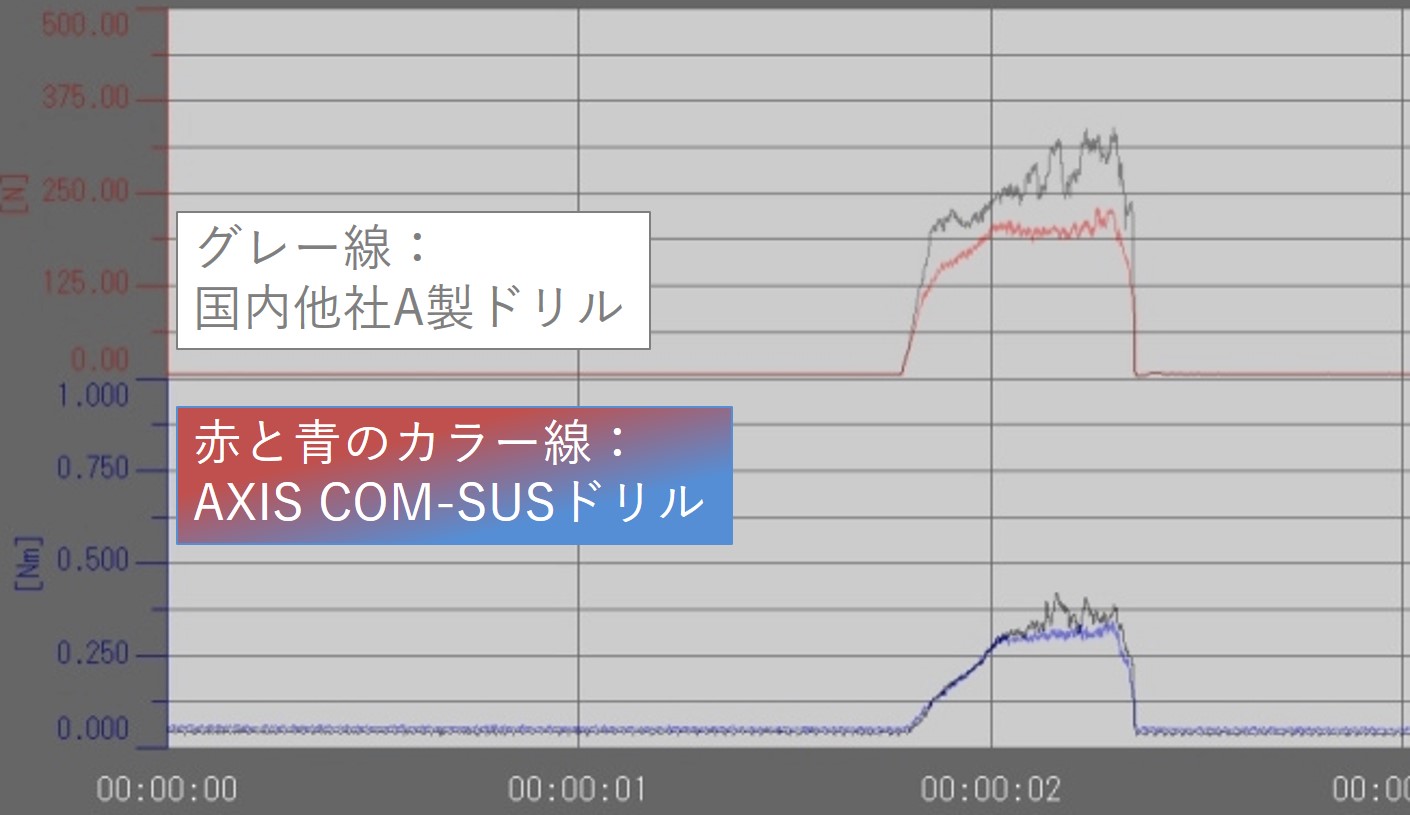

Comparison of thrust value and torque

Measurement result of maximum thrust value by Kistler

Japanese micro drill manufacturer A: 340N

AXIS: 230N

Cutting force is improved over 30%.

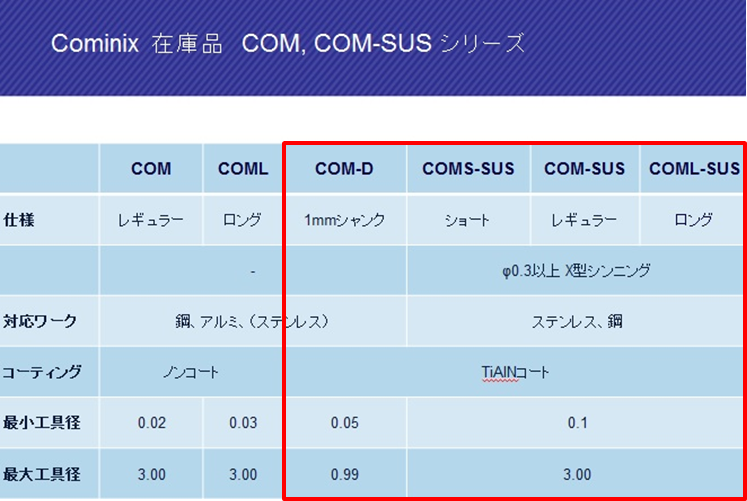

4. Product lineup

All AXIS drill of over Φ0.5 COM-SUS series and COM-D series which Cominix standard inventory, are MMP-treated.