magafor: Spotting drills (Centering drills)

Product introduction and comparing test

Here, we are featuring our new standard inventory product.

In the product comparison test, we compared and verified DUO-MAG which is recommended by Cominix, and products of other manufacture in Japan.

Outline

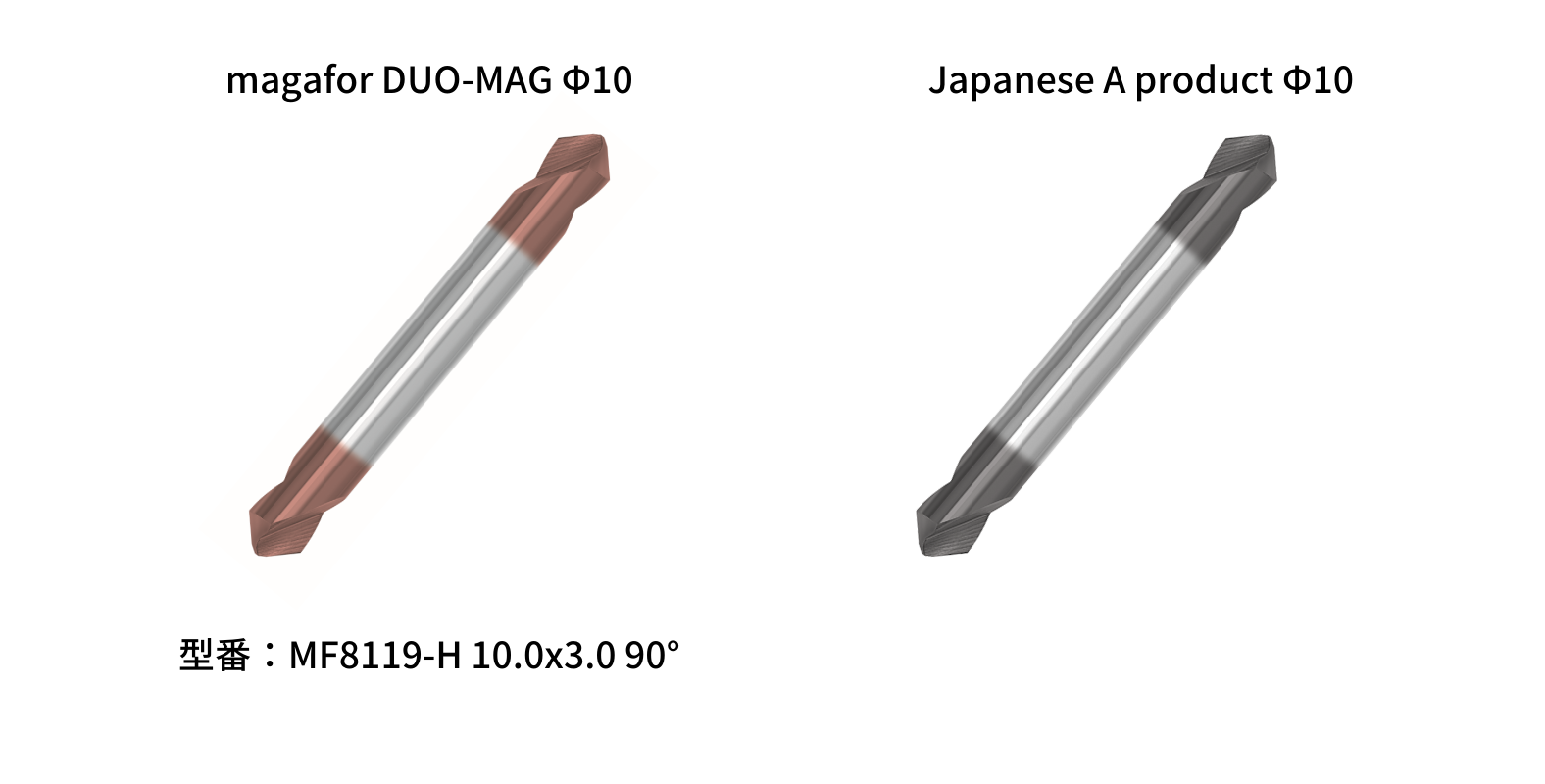

Spotting drills are used as pre-processing for drilling that requires strict position accuracy. Nowadays, both tools and machines have high accuracy and high rigidity. Therefore, in the general machinings which are not require spotting accuracy and deep hole, it is used for securing hole accuracy, but also for chamfering. Cominix has prompt delivery inventory products of magafor which is French tool manufacture. Their products are very unique and have good cost performance.In 2019, there were new lineup of many products, so we tested DUO-MAG which is double NC spotting drill with carbide coated, and the tools of Japanese manufacturer.

INDEX

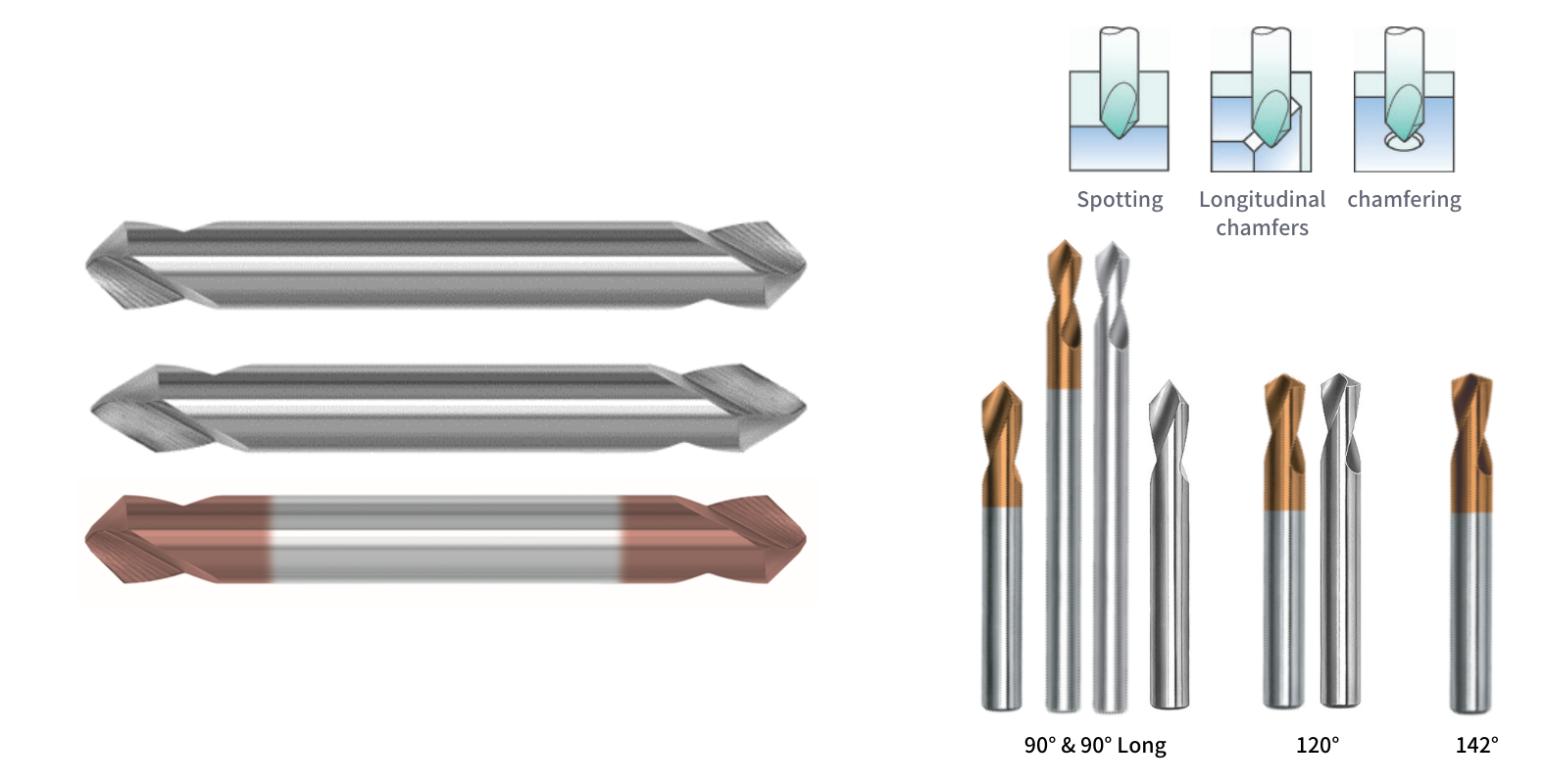

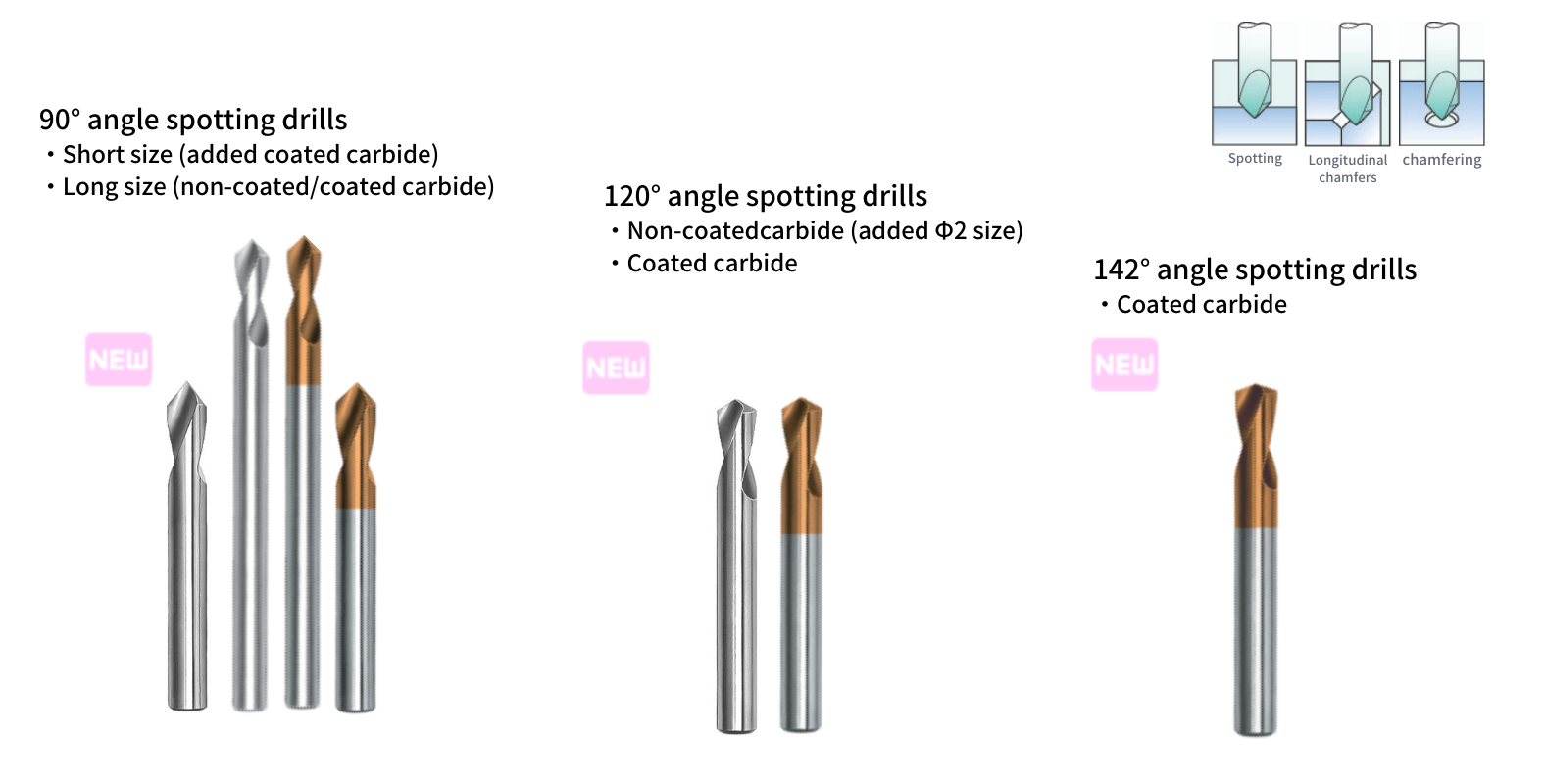

New lineup of prompt delivery inventory

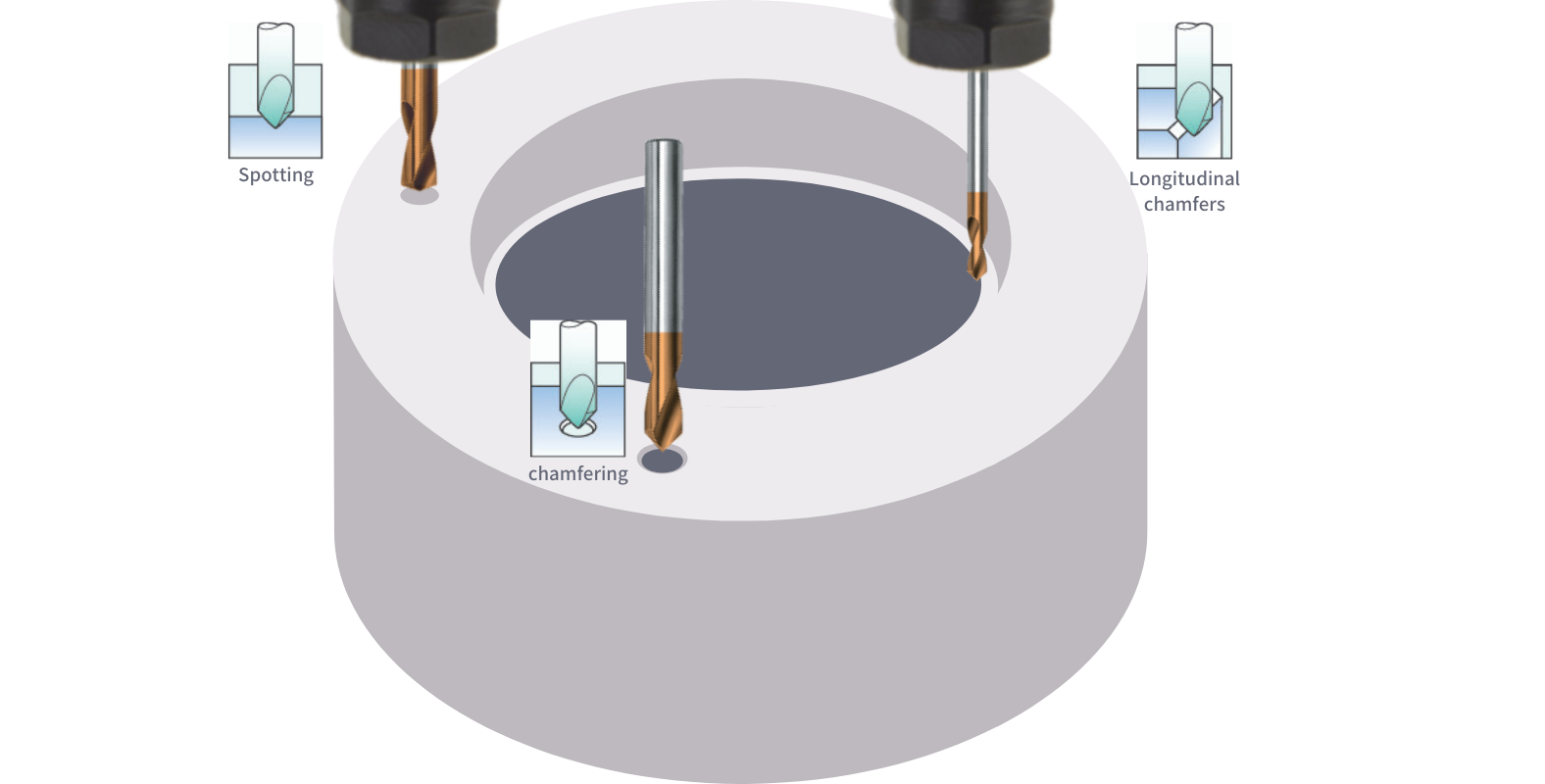

Suggestions for how to use each spotting drills

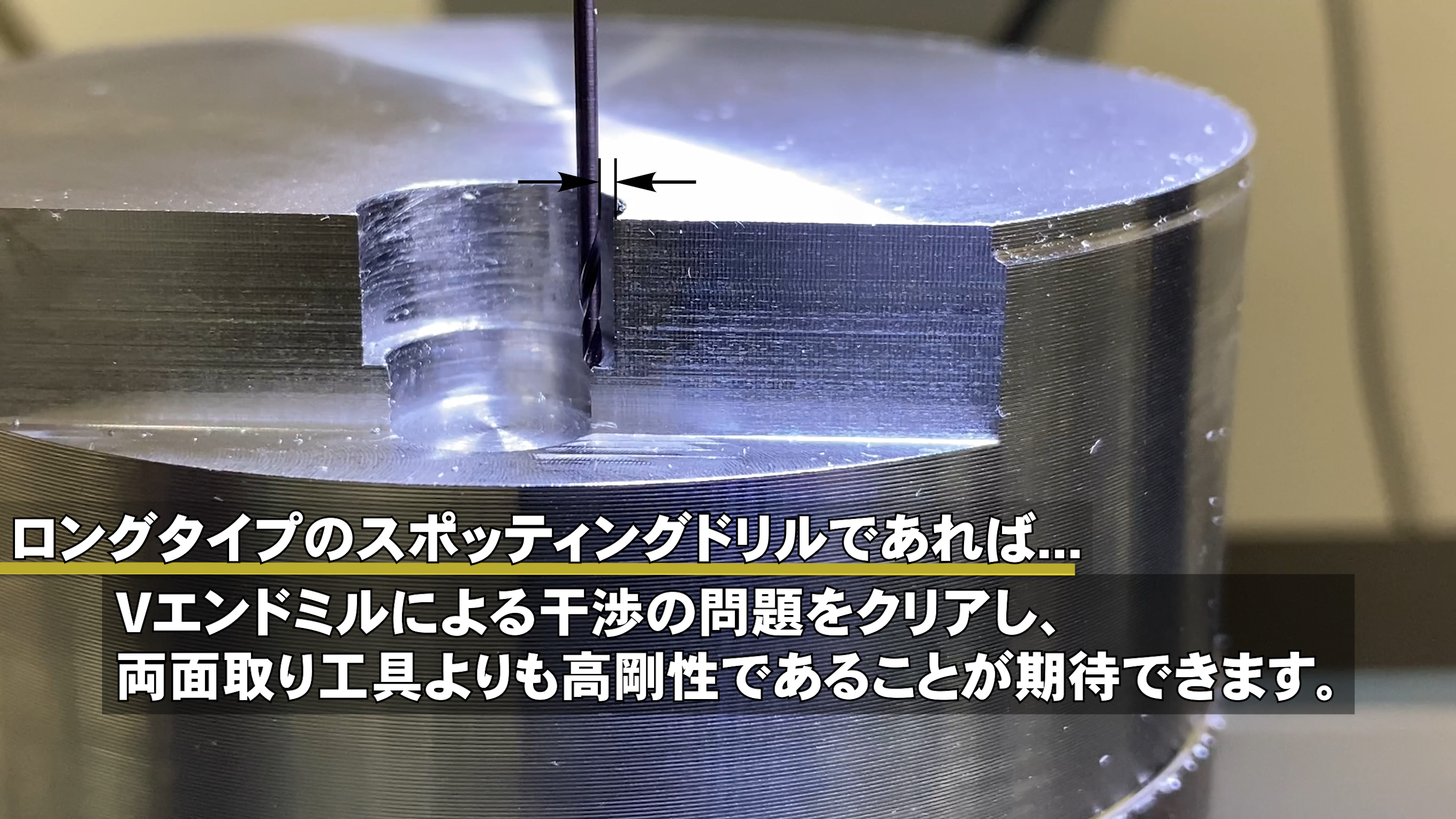

Suggestions for how to use each spotting drills The long type spotting carbide drills can be used not only for chamfering holes, but also for deburring in milling in interfering parts and narrow space. The 142 ° angle spotting drills may use for spotting of tip angles of 120 °, 135 °, and 140 °.

*TIPs: Please pay attention for the tip angle tolerance of the drill when using 140° angle drill for spotting.

There are 140 ° angle drills with ± 2 ° tolerance, but it is 142 ° ± 1 ° for magafor products, which may interfere the tip angle of drill.

Also for step blind hole chamfering.

Please watch the video in this article for more detail.

2.Durability test (magafor vs. Japanese center drill manufacturer)

-

Machine

Mazak VCN-430A(BT40) -

Workpiece clamping condition

Size: 200mm square x 50mm height

Workpiece material: SCM440

Tools for test

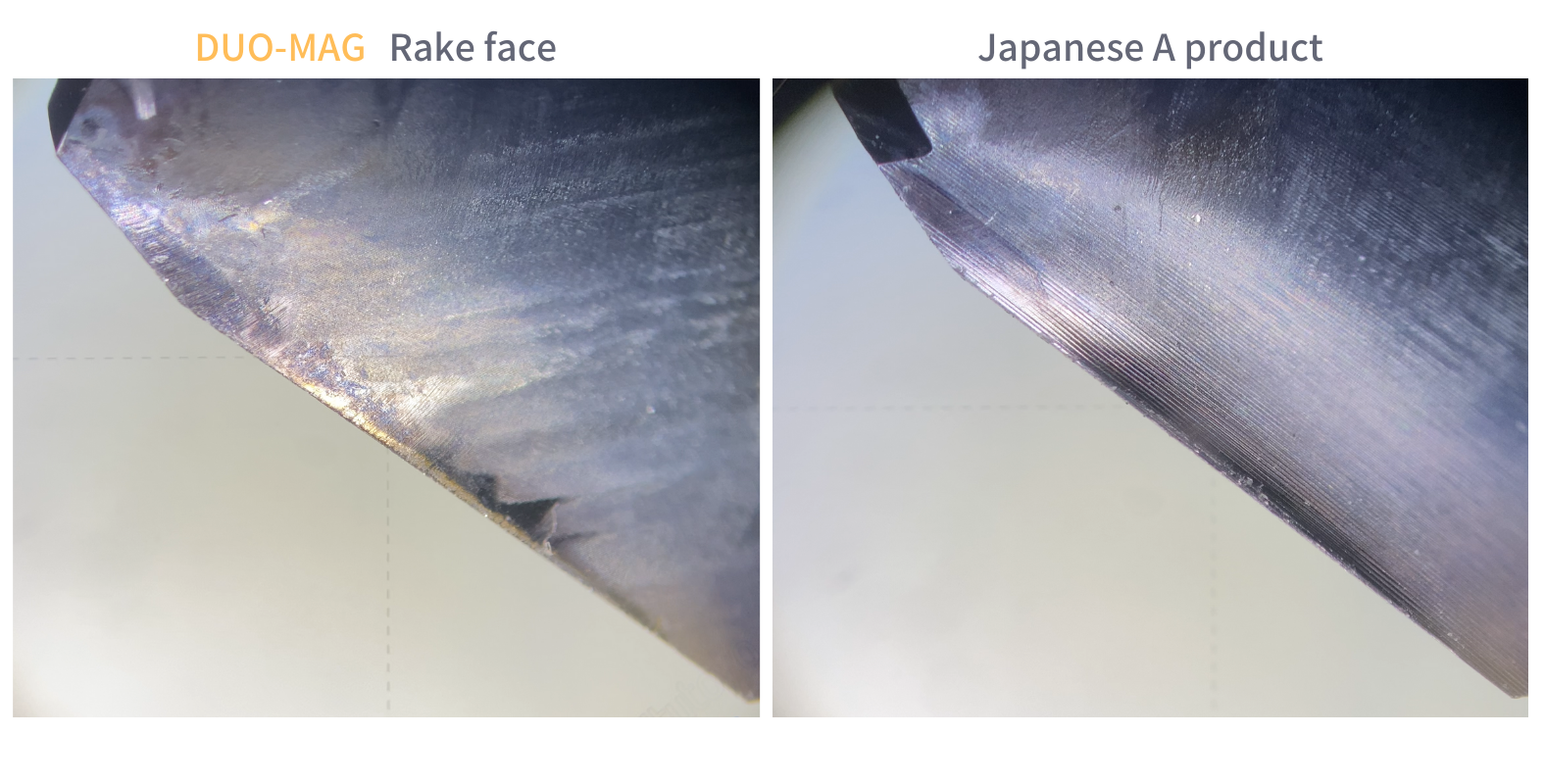

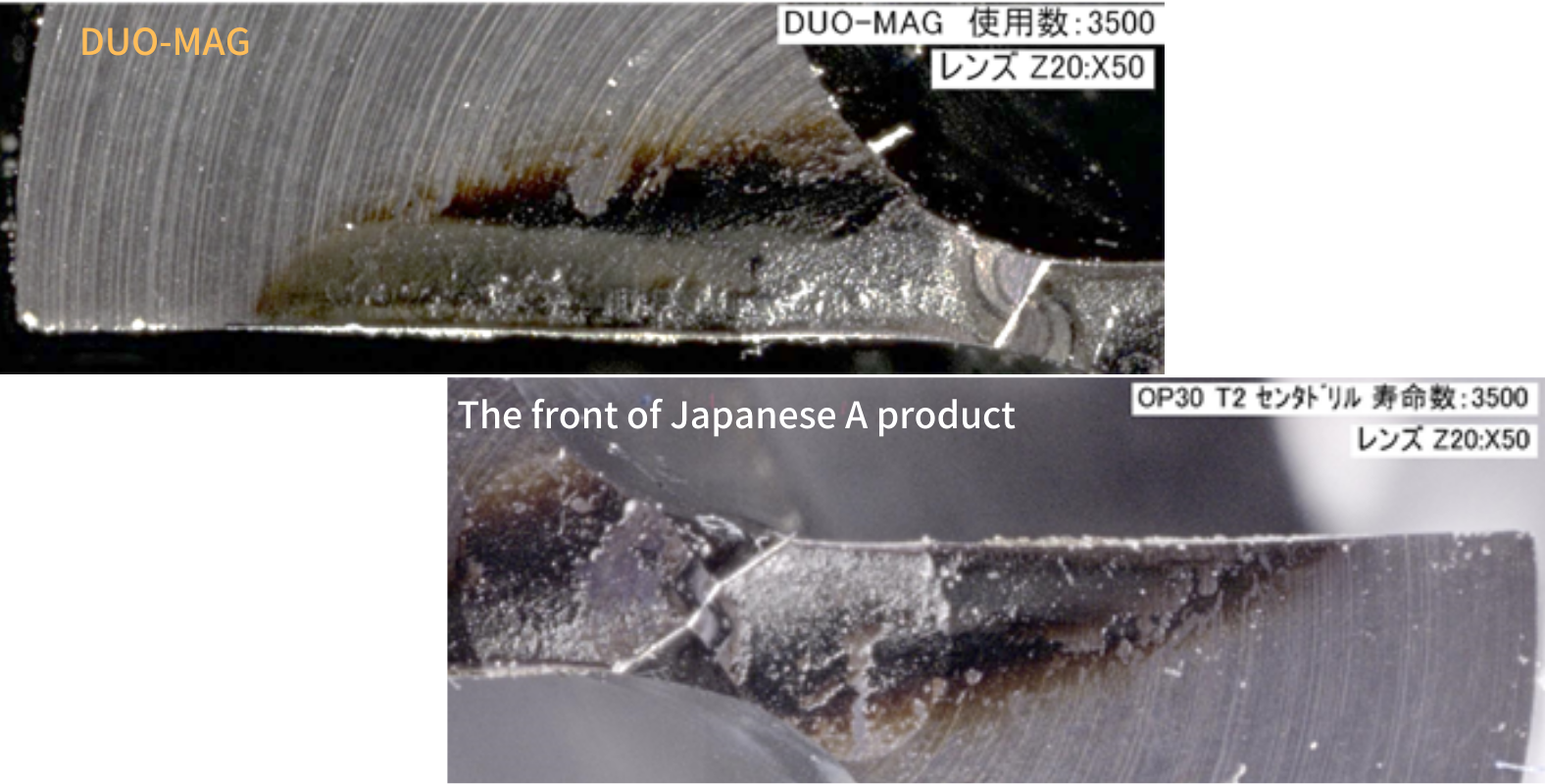

Edge comparison after 3,000 holes (approx. 15m) machining.

There was no damage or welding even 3,000 holes machining on SCM440.

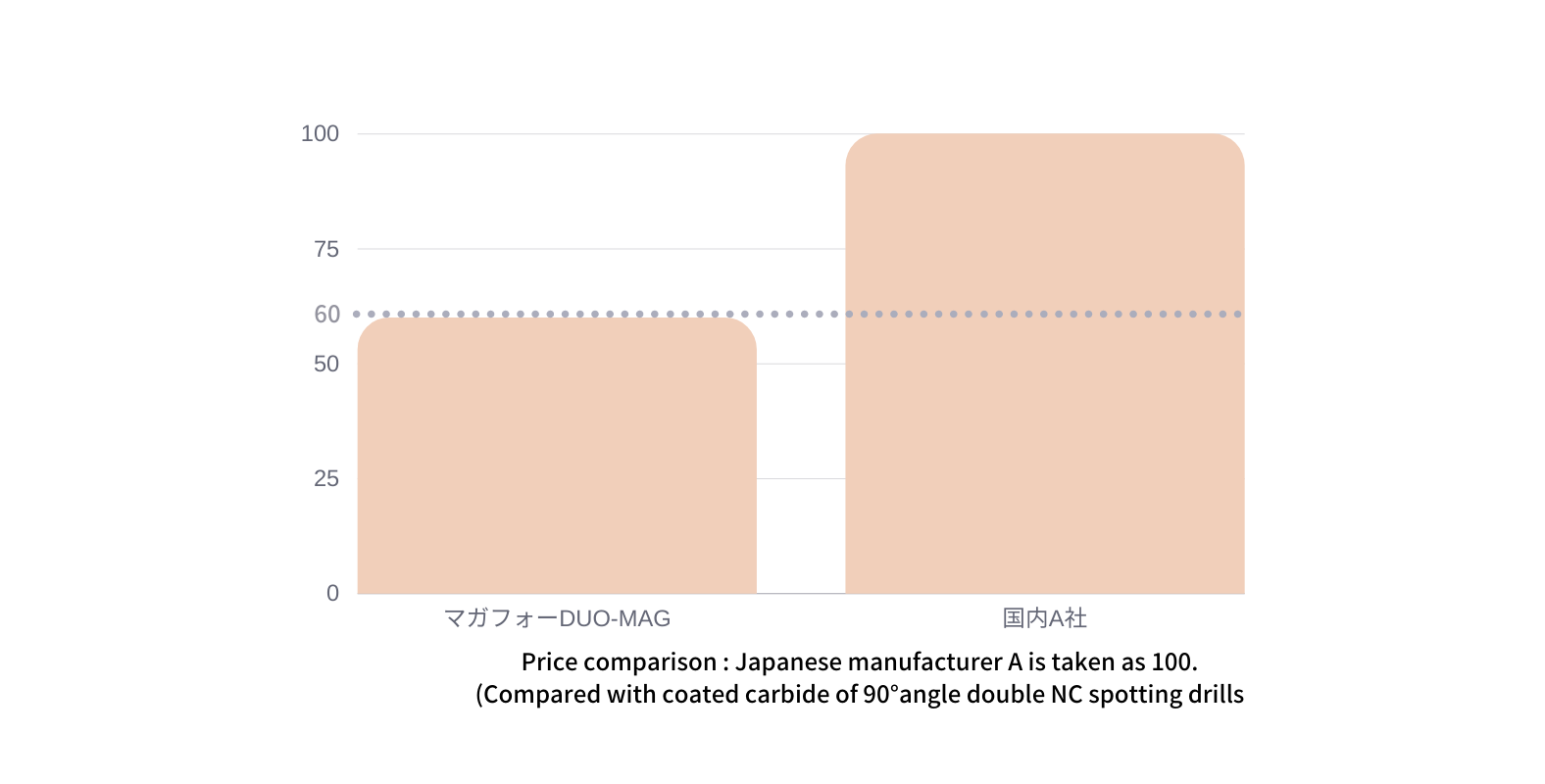

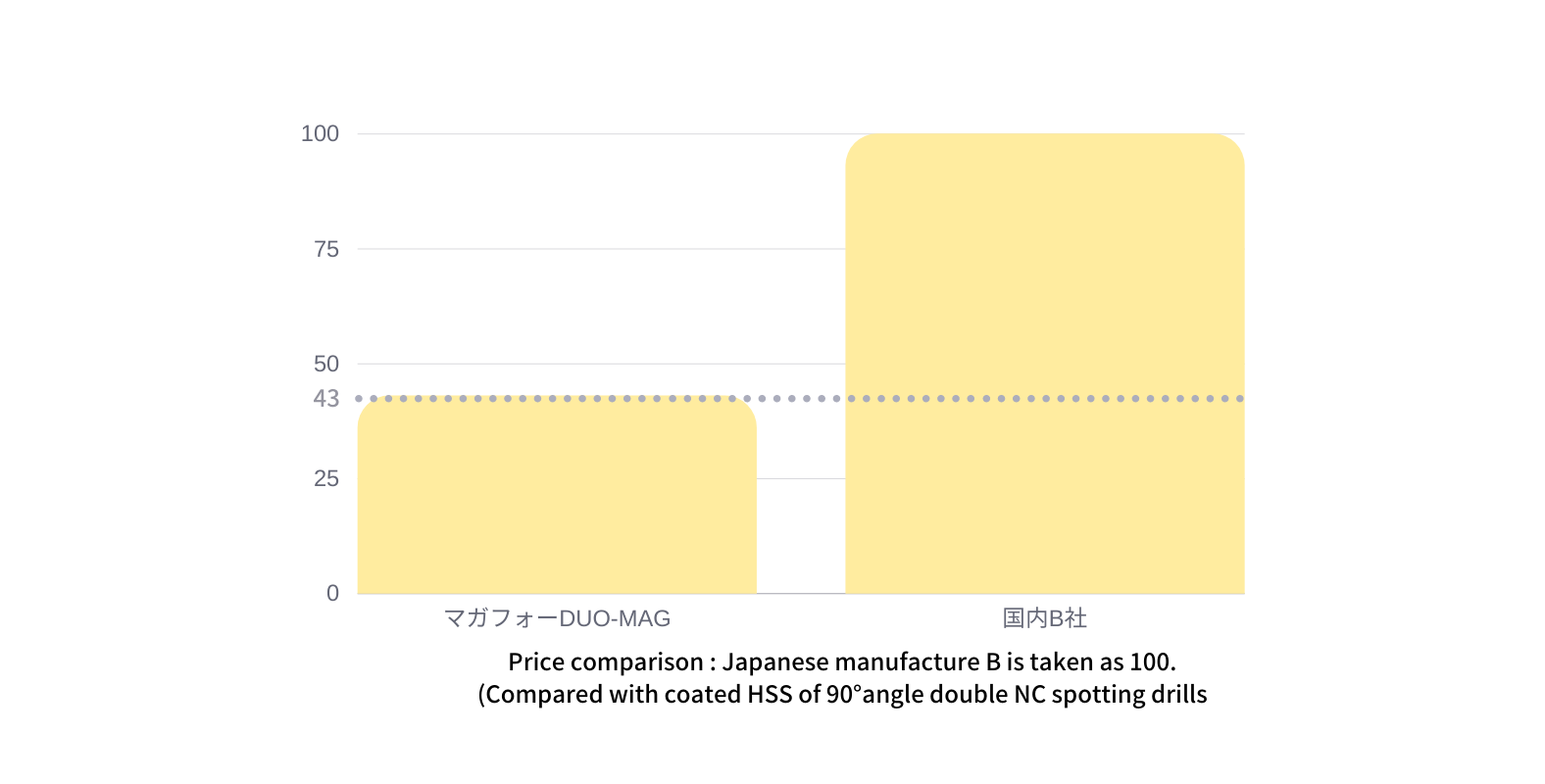

3.Price comparison

4.The example of changing tool of Japanese user

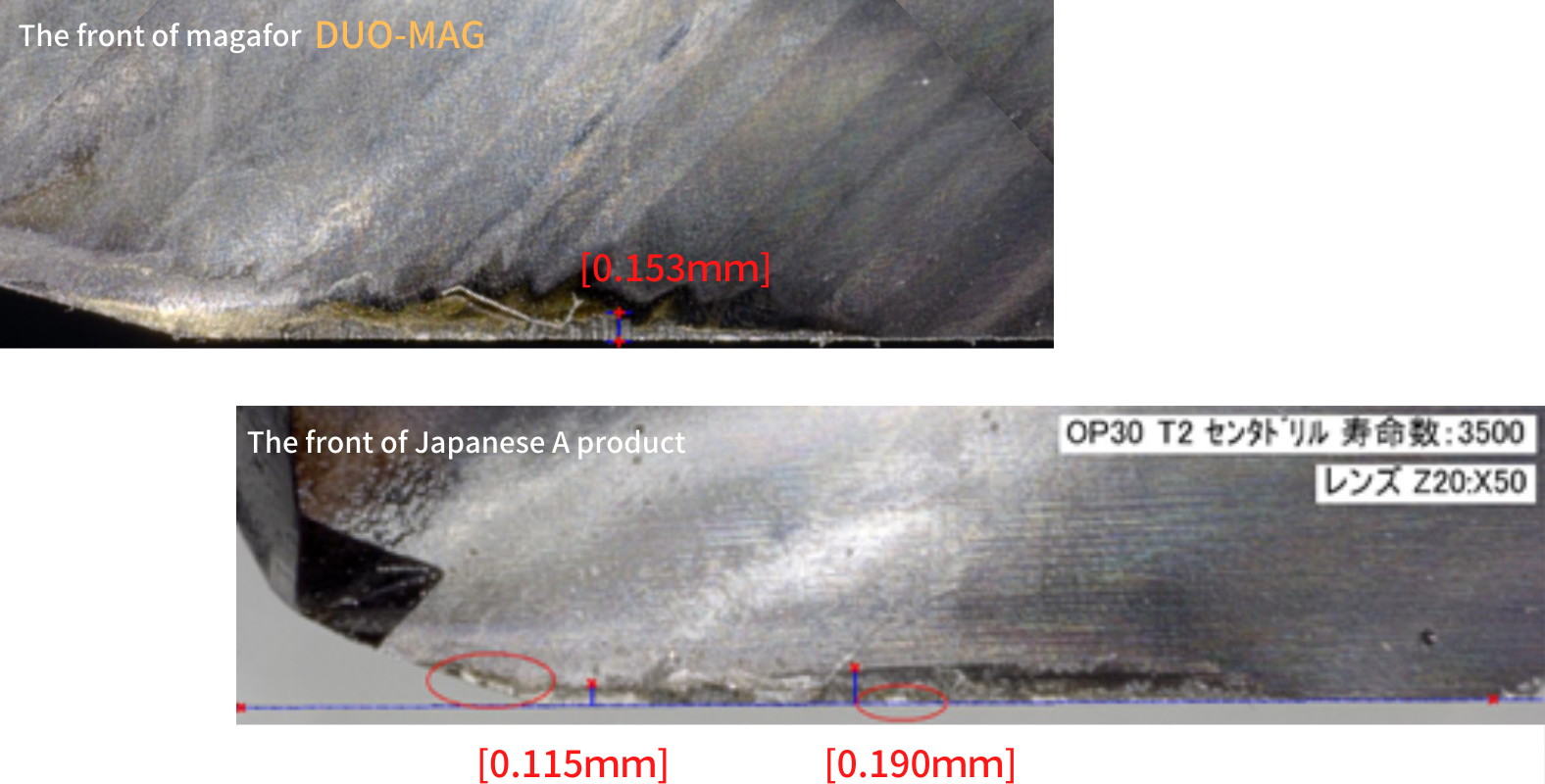

The example of changing tool from Japanese manufacturer product A to magafor product.

This is for workpiece of manganese which is high alloy steel.

Machine: BT30, external coolantCutting condition: 3,200 rotation/min, f=0.15/rev, 5mm per one hole x 3,500 holes

(machining for 17.5m)

Testing tools: DUO-MAG vs. Japanese manufacture A's product (coated carbide)

The workpiece material is easily generates heat during machining and the tool is easily got damages, but DUO-MAG was selected due to cost advantage and the same performance as current tool.

5.Explanation video

How to use magafor products