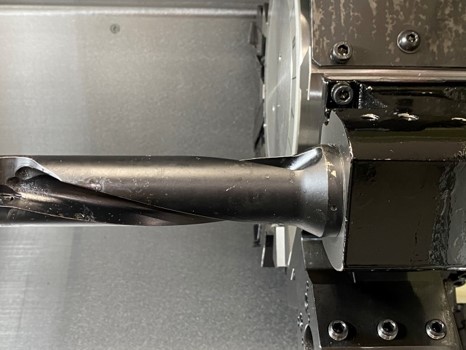

Stable machining of large diameter x deep holes Walter D3120

High rigidity indexable insert drill

The high-rigidity design of the straight flute enables stable machining, especially when drilling holes by turning.

One indexable insert shape for outer and inner seat.

You have 3 options for the breaker.

High rigidity design with straight cutting edge.

Stable machining is possible even in large diameter and deep hole.

-

Walter D3120

-

General indexable insert drill (Japanese other company's)

Size lineup

Diameter: Φ16~42

Length: 2D~4D

4 cutting edges with one indexable insert shape for outer and inner seat

3 options of breaker: Comventiional type (E57), high stability type (A57), and light cutting type (E67)

Test data

-

Machine

Mazak QT-compact200MY -

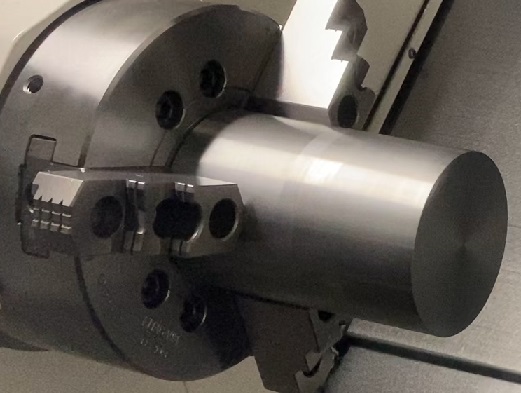

Workpiece

Φ80 external diameter x 140mm length

Workpiece material: S45C

Cutting condition:Vc=80m/min f=0.1mm/rev Depth of cut100mm

Result: No vibration and quiet machining noise compared to Japanese other company's product.

Stable chip control from the start to 100mm.

-

Walter D3120

-

Japanese other company's product

Machining video

-

For large diameter and deep holes machining

High rigidity holder and insert makes hard to vibrate.

-

3 types breaker

You can choose the proper breaker depending on machining application.