Web tour Walter factory in Germany

Cutting tool manufacturer in Germany

It takes 13 hours by direct flight from Japan.

We invite you to a web tour that makes Walter, a German cutting tool manufacturer, more closer.

Reference

(https://www.walter-tools.com/en-gb/campaigns/Pages/history-walter.aspx)

Walter production sites

There are 4 production sites in Germany: Tübingen, Münsingen, Zell, and Frankfurt.

Overseas production sites are in France, India, and China.

Company headquarters in Tübingen

There are production site of indexable milling cutters and turning holders, Technology Center, and Walter museum.

-

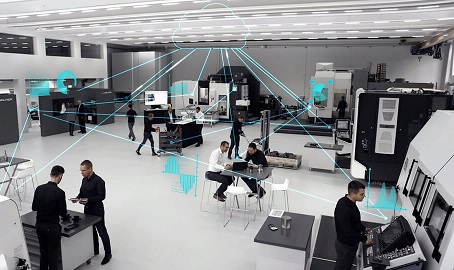

Technology Center

1st floor is testing room, and 2nd to 3rd floor is seminar room.

-

A camera is installed in the processing equipment.

Test processing is being broadcast to the whole world.

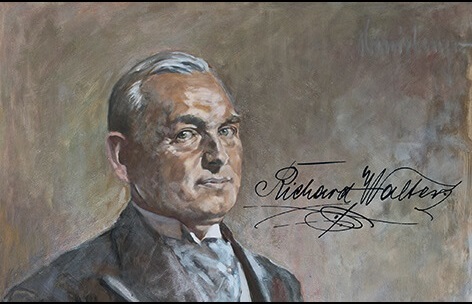

Walter museum

Just opened in May 2019

Established to commemorate the 100th anniversary of Walter's founding.

It is directly connected to the Tübingen factory.

Introducing the history of the company along with personal belongings, research tools and cutting tools used at that time.

-

Richard Walter, founded in 1919.

He also visited Japan and sold tools. -

Global expansion in 1963.

We are displaying products that have been successful worldwide.

World's first carbide milling cutter

The first carbide milling tool was released in 1927.

It has become a new standard for cutting tools.

It looks like inserting a lot of boring bars.

Other production site in Germany

-

Münsingen Factory

Product range: Complete production of carbide indexable inserts

-

Zell Factory

Product range:

Production of Taps and indexable endmill (Conefit) -

Frankfurt Factory

Sales Headquarters in Germany

Production range: Production of drill and regrinding

Walter's traditional apprenticeship training system

Human resource development rooted in the German craftsman guild

At the Frankfurt factory, Walter secure, train, and pass on skills through an apprenticeship system (corporate apprenticeship training system) rooted in the traditional craftsman guild of medieval Europe.

Currently, about 16 students over the age of 15 are enrolled, and together with Walter's trainer, they are making improved parts for the production line and making original student works.

In order to improve quality and accuracy, trainee learn how to use machining equipment, how to draw drawings, cutting / grinding and assembly. Walter is supporting career development to be able to work anywhere.

It is unique that Walter, a tool manufacturer, trains cutting. That makes us feel Walter's social contribution to the cutting industry as well.

Even 100 years after their founding, they will continue to pass on the traditional manufacturing spirit to the next generation.