Introduces New MULTI-MASTER Milling Heads with 1.5xD

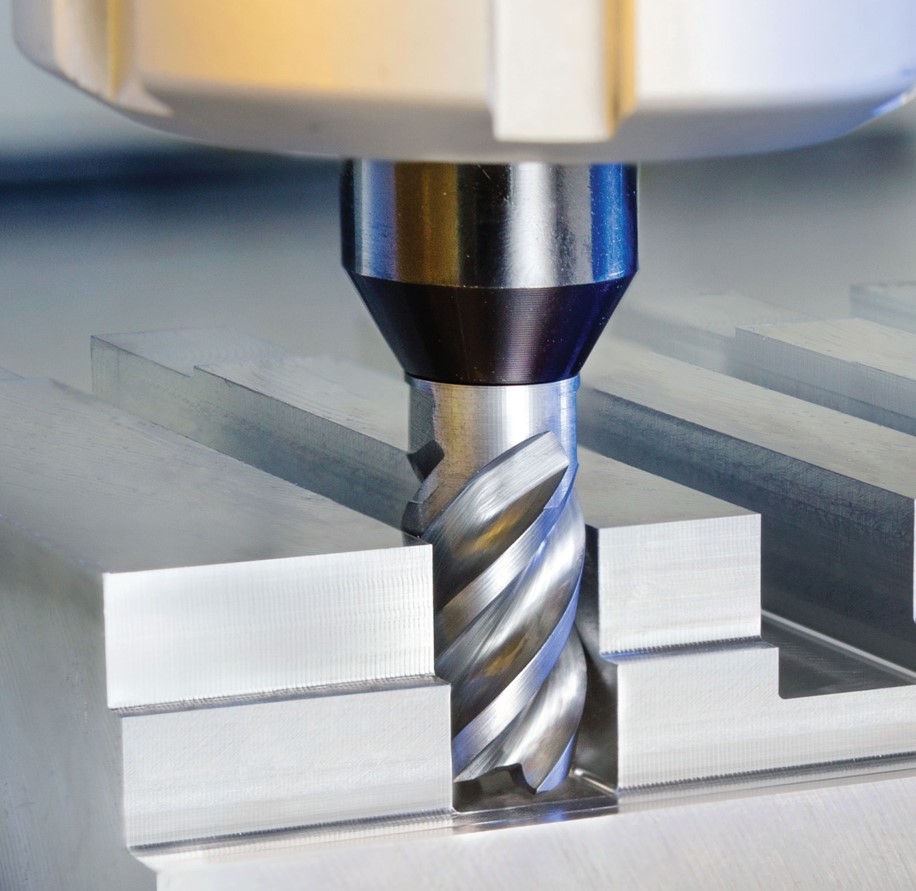

MM EC/MM ERS

MM EC: Φ8 indexable heads with 4 flute and 7 flute

MM ERS: Φ8 indexable heads with roughing endmill 4 flute

* Here is the recommended conditions for side milling with BT30 based on actual machining data.

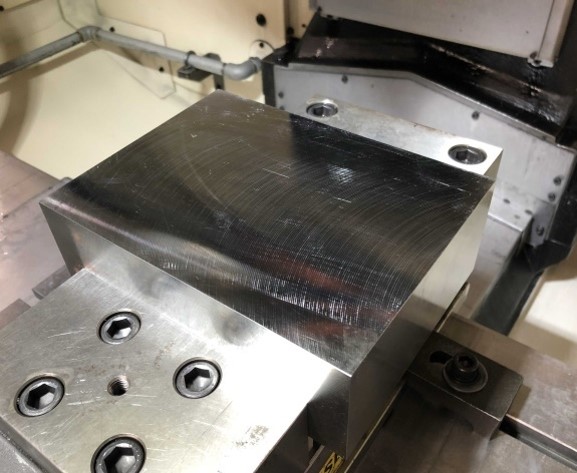

Side milling with BT30

Cutting condition difference by different heads

-

Machine

ROBODRILL α-D14LiA5 BT30

-

Tool

①MM EC120H18R05CF-4T08 IC908

②MM ERS120B18-4T08 IC908

(ERS is roughing head) -

Workpiece material

SCM440

Test result

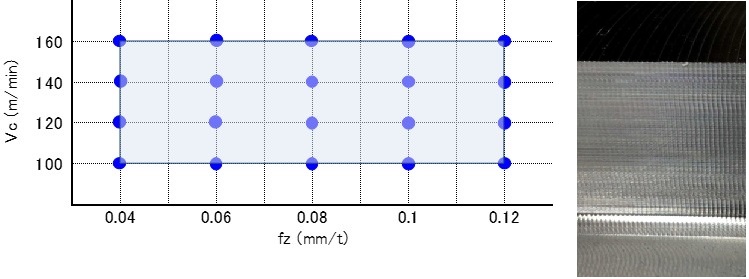

Shoulder milling with MM EC-CF head

Side surface

Cutting condition: Vc=160m/min, fz=0.12

MM EC-All the test items passed at good condition.

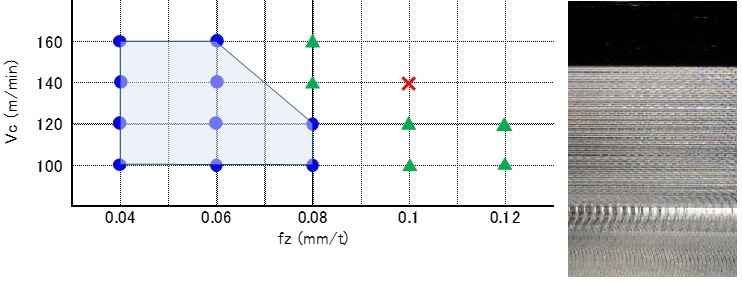

Test result

Shoulder milling with MM ERS head

Side surface

Cutting condition: Vc=140m/min, fz=0.1

MM ERS head vibrated under high speed cutting.

Please refer Iscar web site for more detail.

EC head (7,9 flute):

https://www.iscar.com/eCatalog/Family.aspx?fnum=4206&mapp=IT&app=0

EC head (4 flute):

https://www.iscar.com/Ecatalog/Family.aspx?fnum=4207&mapp=ML&app=125

ERC head:

https://www.iscar.com/Ecatalog/Family.aspx?fnum=4208&mapp=ML&app=132

-

Reduce tool replacement time

Improvement of tool replacement time especially for automatic machines with a small space for tool exchange.

-

1.5xD

is now a standard product.

-

Slotting

We didn't get good result with slotting by using BT30 machine. Slotting is not recomended for this product.